Preparation method of graphene foam and precious metal nano-particle composite material

A technology of graphene foam and nano particles, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as unfavorable industrial practical applications, and achieve the goal of improving its comprehensive performance, simple method, and high specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Dissolve 50mg of graphene oxide and 100mg of chloroauric acid in 100ml of deionized water, and mix them uniformly by ultrasonic;

[0018] Immersing the obtained product in liquid nitrogen to freeze, followed by freeze-drying the obtained solid;

[0019] The product obtained after the drying was completed was heated to 250° C. in air for 10 hours to obtain a graphene foam-gold nanoparticle composite material.

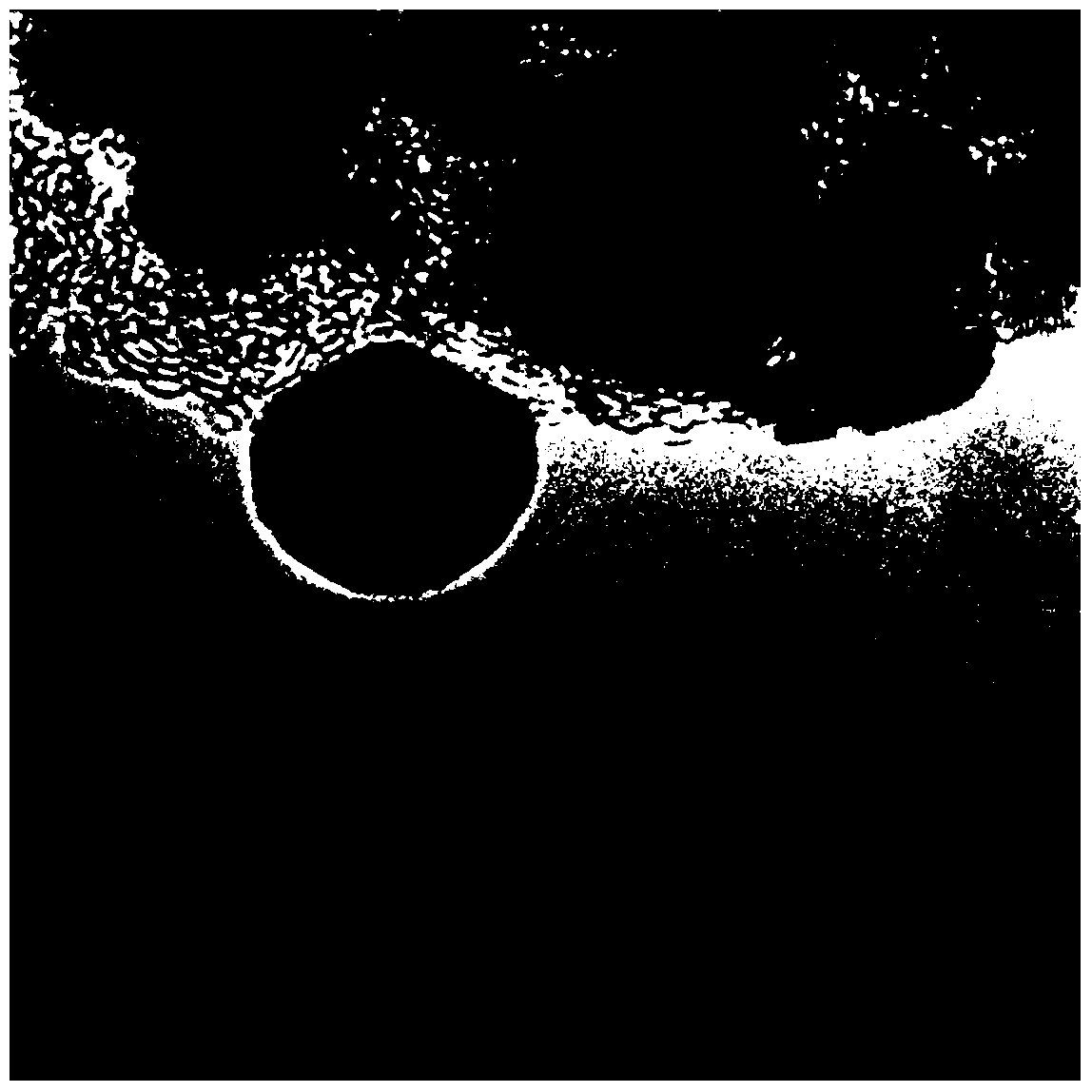

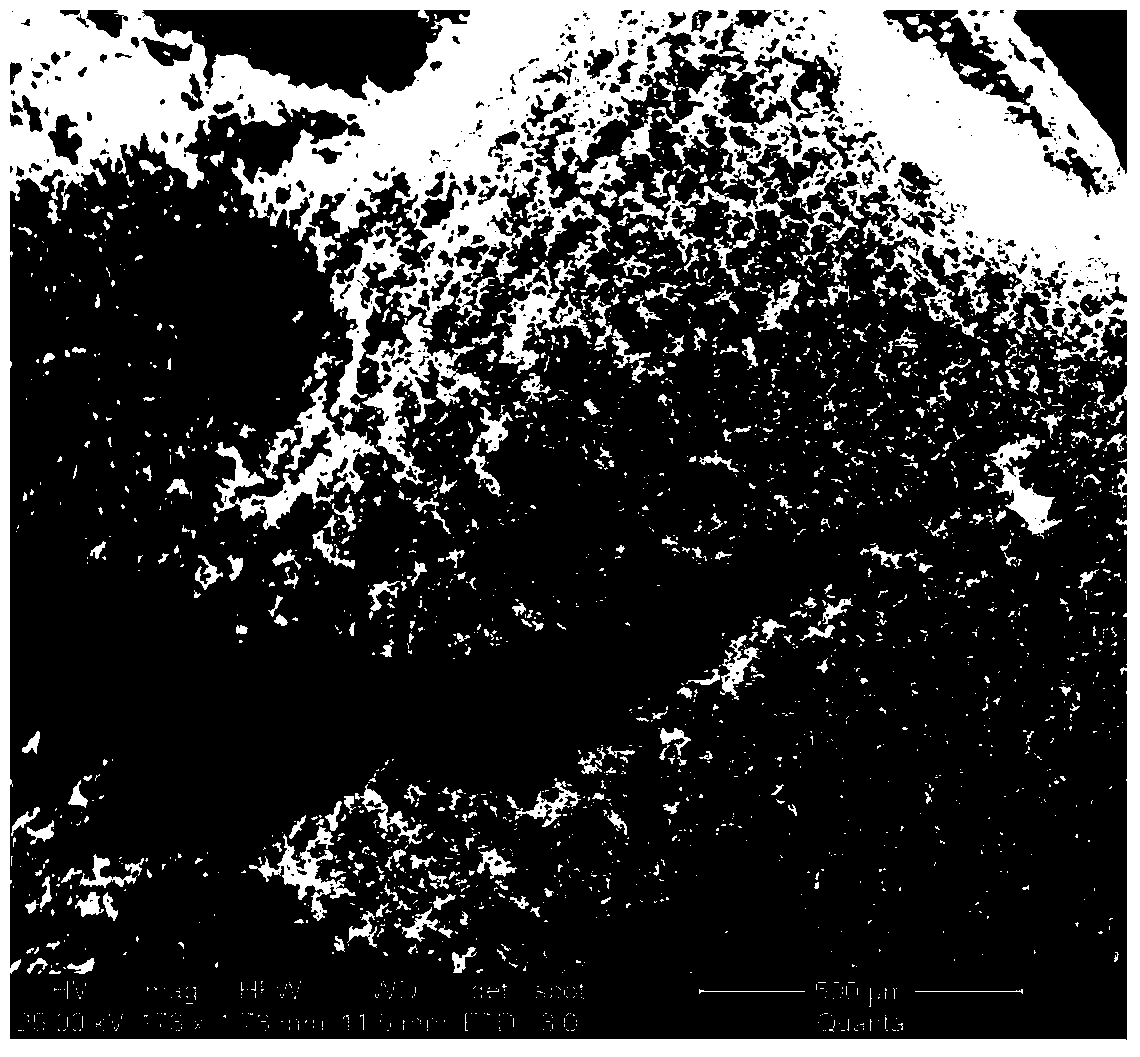

[0020] The product was characterized by transmission electron microscopy, and the results were as follows: figure 1 shown. The product was characterized by scanning electron microscopy, and the results were as follows: figure 2 It can be seen that the composite material is a porous structure.

Embodiment 2

[0022] Dissolve 10 mg of graphene oxide and 30 mg of silver nitrate in 20 ml of deionized water, and mix evenly by stirring;

[0023] The obtained product is subjected to refrigerating compressor freezing and drying;

[0024] The obtained product was heated to 500° C. for 10 minutes in hydrogen to obtain a graphene foam-silver nanoparticle composite material.

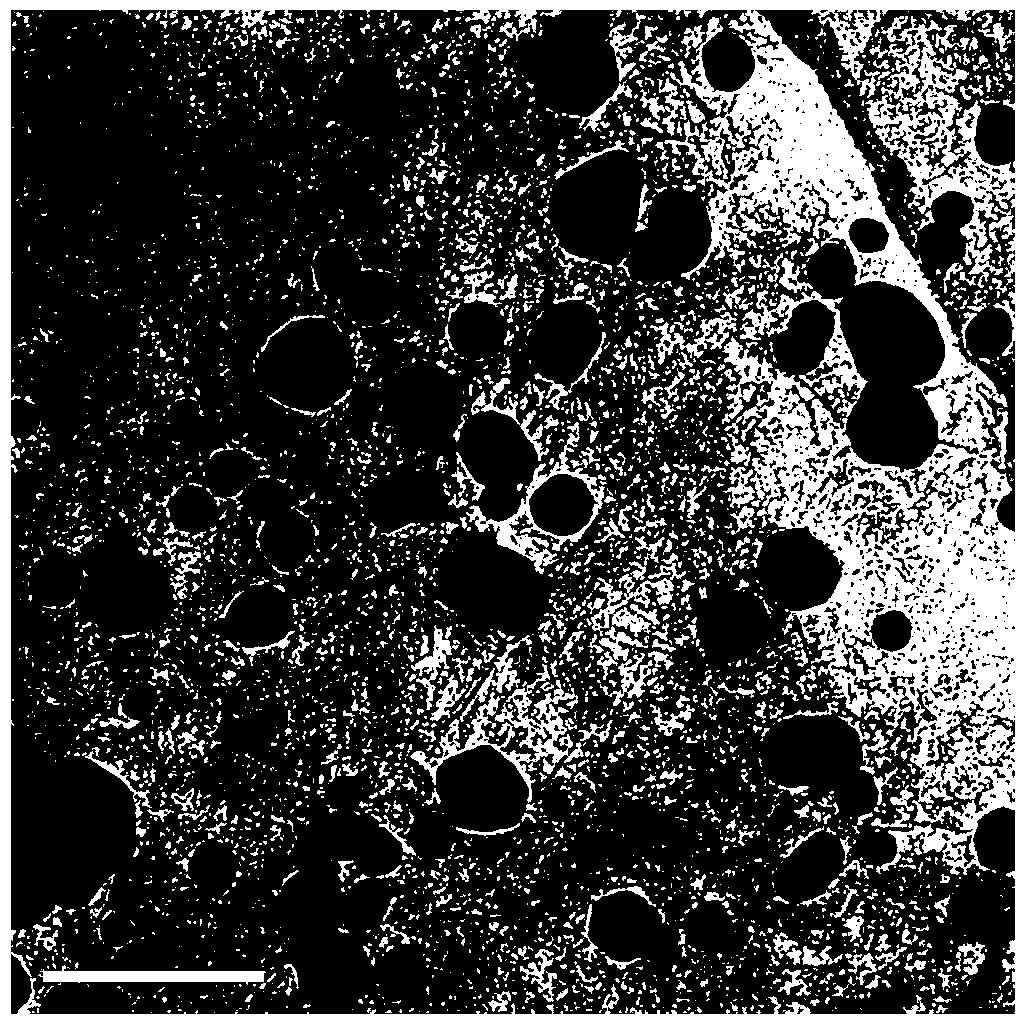

[0025] The product was characterized by transmission electron microscopy, and the results were as follows: image 3 shown.

Embodiment 3

[0027] Dissolve 100mg of graphene oxide and 100mg of sodium chloroplatinate in 100ml of deionized water, and mix them uniformly by ultrasonic;

[0028] The obtained product is subjected to refrigerating compressor freezing and drying;

[0029] The obtained product was heated to 1100° C. for 5 seconds in argon to obtain a graphene foam-platinum nanoparticle foam composite material.

[0030] The obtained result is similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com