Phosphorous and nitrogenous UV-cured flame retardant and preparation method thereof

A phosphite and flame retardant technology, which is applied in the field of UV-curable nitrogen-phosphorus flame retardants and their preparation, can solve the problems of low flame retardant efficiency, complicated preparation steps, etc., and achieves high production efficiency and curbs Effect of flame retardant migration and high flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

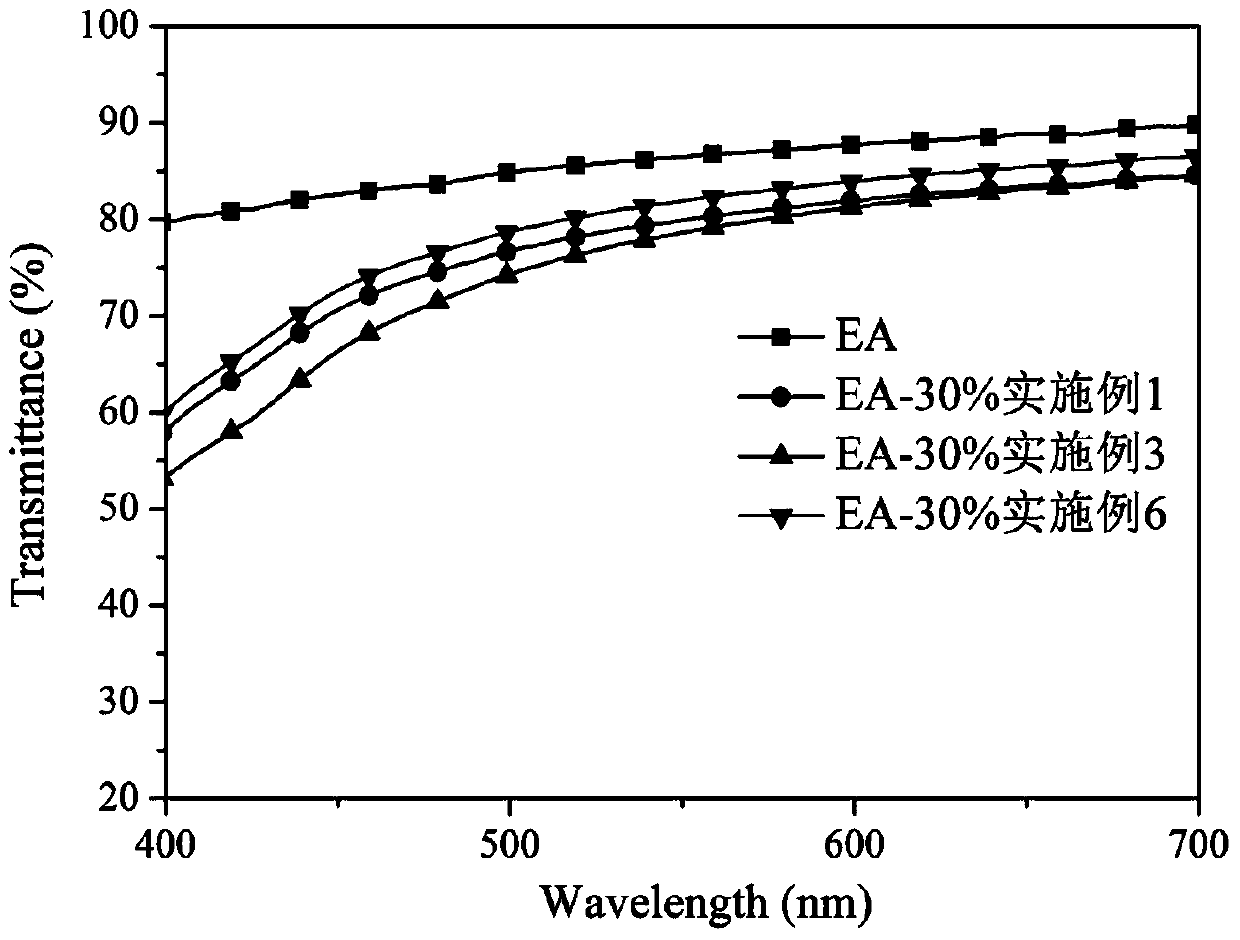

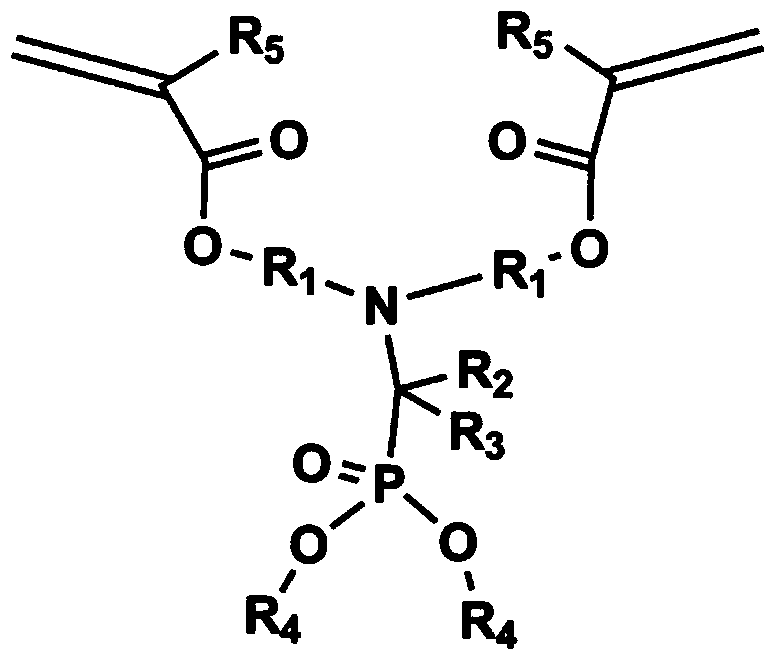

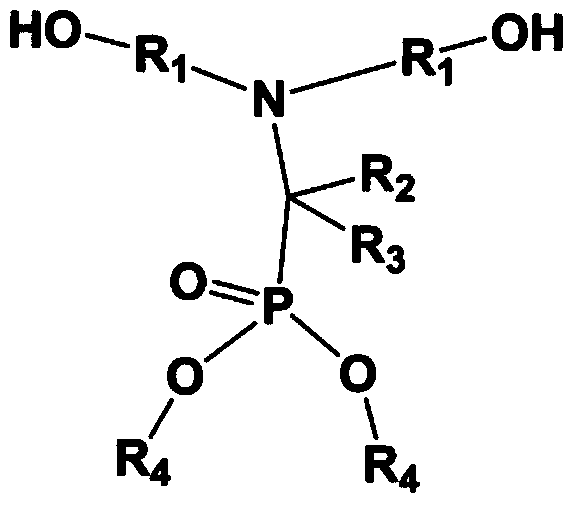

Embodiment 1

[0032] In a 500ml three-neck flask equipped with mechanical stirring and a constant pressure dropping funnel, add 0.3mol (24.3g) of 37%-40% formaldehyde aqueous solution; after stirring at 40°C for 1 hour, slowly drop 0.3mol (31.5g) of Diethanolamine, heat preservation reaction for 2 hours; the reaction solution was distilled under reduced pressure at 0.094MPa to obtain the intermediate; after the intermediate temperature was raised to 60°C, 0.3mol (41.4g) diethyl phosphite was added dropwise, and the heat preservation reaction was carried out for 3 hours. A yellow transparent liquid was obtained. Then take 10.21g (0.04mol) of the yellow liquid and 125ml of chloroform into a 250ml three-necked flask, control the temperature at -5-10°C, add 12.14g (0.12mol) of triethylamine and stir for 1 hour, then add 10.86g (0.12mol) of acryloyl chloride, after 4 hours of reaction, the temperature was raised to room temperature (25°C), and the reaction was continued for 12 hours; Washed wit...

Embodiment 2

[0036] In a 500ml three-neck flask equipped with mechanical stirring and a constant pressure dropping funnel, add 0.3mol (24.3g) of 37%-40% formaldehyde aqueous solution; after stirring for 1 hour at 40°C, slowly drop 0.3mol (39.9g) of Diisopropanolamine, heat preservation reaction for 2 hours; the reaction solution was distilled under reduced pressure at 0.094MPa to obtain the intermediate; after the intermediate temperature was raised to 60°C, 0.3mol (41.4g) diethyl phosphite was added dropwise, and the heat preservation reaction After 3 hours, a yellow transparent liquid was obtained. Then take 11.3g (0.04mol) of the yellow liquid and 125ml of chloroform into a 250ml three-necked flask, control the temperature at -5-10°C, add 12.14g (0.12mol) of triethylamine and stir for 1 hour, then add 10.86g (0.12mol) of acryloyl chloride, after 4 hours of reaction, the temperature was raised to room temperature (25°C), and the reaction was continued for 12 hours; Washed with salt wate...

Embodiment 3

[0040] In a 500ml three-neck flask equipped with mechanical stirring and a constant pressure dropping funnel, add 0.3mol (35.7g) of 37%-40% acetaldehyde aqueous solution; after stirring at 40°C for 1 hour, slowly drop in 0.3mol (39.9g) Melted 3,3'-dihydroxydiphenylamine, heat preservation reaction for 2 hours; the reaction solution was distilled under reduced pressure at 0.094MPa to obtain the intermediate; after the intermediate was heated to 60°C, 0.3mol (41.4g) of diphosphite was added dropwise Ethyl ester was incubated for 3 hours to obtain a yellow transparent liquid. Then take 14.0g (0.04mol) of the yellow liquid and 125ml of chloroform into a 250ml three-necked flask, control the temperature at -5-10°C, add 12.14g (0.12mol) of triethylamine and stir for 1 hour, then add 10.86g (0.12mol) of acryloyl chloride, after 4 hours of reaction, the temperature was raised to room temperature (25°C), and the reaction was continued for 12 hours; Washed with salt water, and dried wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com