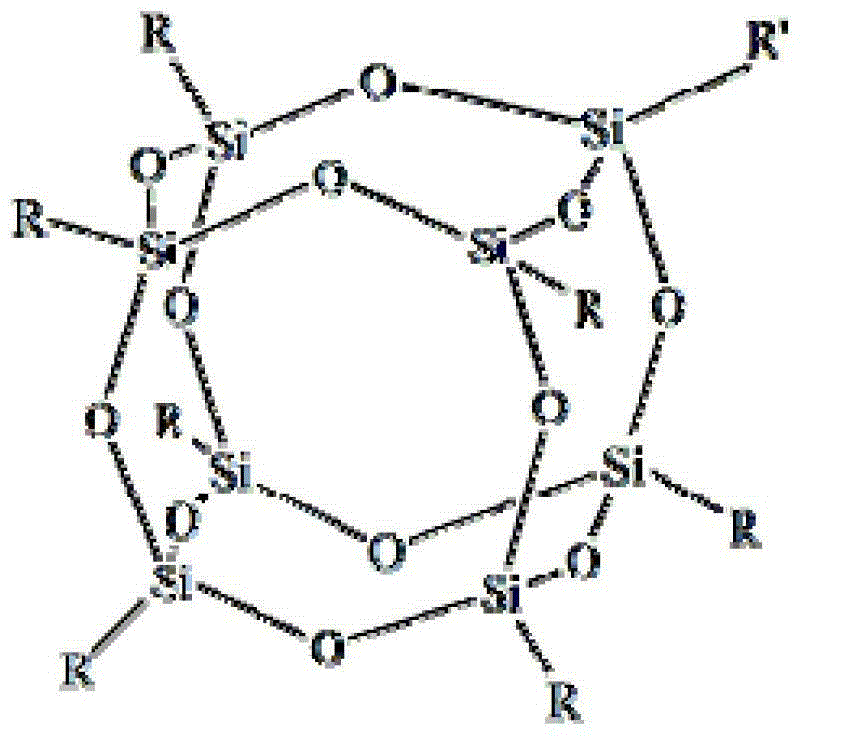

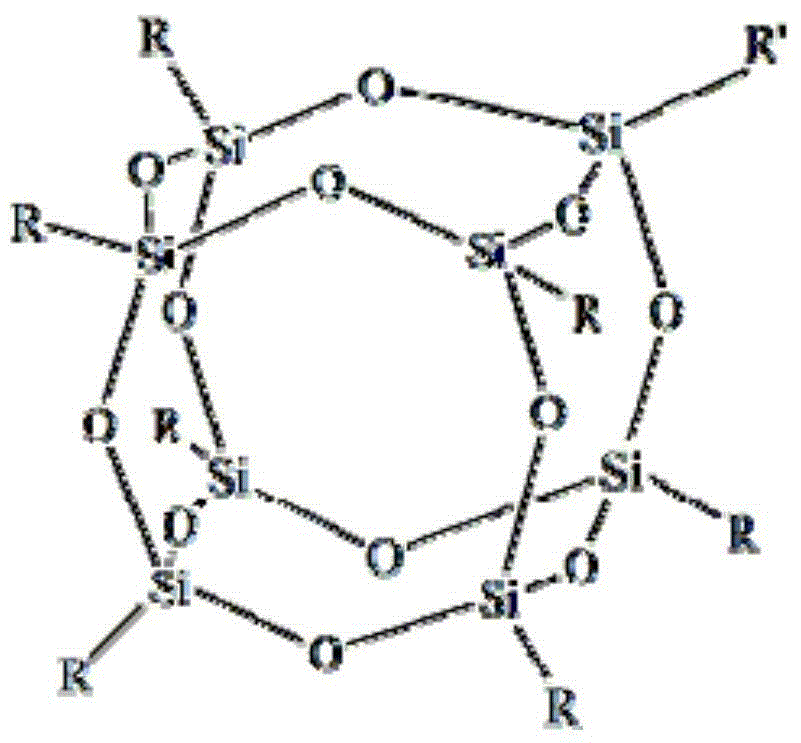

Poss-based hybrid fluorine-containing acrylate resin and its preparation method and application

A technology of fluorine-containing acrylate and acrylic acid, applied in the direction of polyurea/polyurethane coatings, coatings, etc., to achieve the effect of simple synthesis conditions, high-efficiency oil-water separation characteristics, and strong mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In the first step, when equipped with an electric mixer, N 2 Add 12g of butyl acetate as a solvent to the four-necked flask with the gas guide tube, condensing reflux tube and constant pressure funnel, heat up to 75°C and reflux for 30min, and feed N 2 , then mix 1.2g methyl methacrylate, 1.9g butyl acrylate, 2.1g lauryl acrylate, 1.5g-β-hydroxyethyl methacrylate, 0.135g azobisisobutyronitrile and 4g butyl acetate After uniformity, add it to the constant pressure funnel, stir at a speed of 350 rpm, and drop it continuously within 2.5 hours, and continue the insulation reaction for 3 hours after the dropwise addition;

[0039] In the second step, 1.0g of trifluorooctyl methacrylate, 0.019g of azobisisobutyronitrile and 2g of butyl acetate were mixed evenly and added to the constant pressure funnel, and then added dropwise to the reaction system of the first step at a constant speed , continuous dripping within 1.5h, and continue the insulation reaction for 3h after the ...

Embodiment 2

[0043] In the first step, when equipped with an electric mixer, N 2 Add 10 g of butyl acetate as a solvent to the four-neck flask with the gas guide tube, condensing reflux tube and constant pressure funnel, heat up to 90 ° C and reflux for 30 min, and feed N 2 , then mix 0.8g tert-butyl methacrylate, 1.2g isooctyl acrylate, 1.8g hexadecyl acrylate, 1.4g hydroxybutyl methacrylate, 0.104g benzoyl peroxide and 3g butyl acetate Add it to the constant pressure funnel, stir at 350 rpm, drop it continuously within 3 hours, and continue the insulation reaction for 3.5 hours after the dropwise addition;

[0044] In the second step, mix 0.8g hexafluorobutyl acrylate, 0.015g benzoyl peroxide and 2g butyl acetate evenly and add them to the constant pressure funnel, then drop them into the reaction system of the first step at a constant speed, within 0.5h After the continuous dripping, continue the insulation reaction for 2 hours after the dripping;

[0045] In the third step, 4g POSS-b...

Embodiment 3

[0048] In the first step, when equipped with an electric mixer, N 2 Add 11 g of butyl acetate as a solvent to the four-neck flask with air duct, condensing reflux tube and constant pressure funnel, raise the temperature to 80 ° C and reflux for 30 min, and feed N 2 , then mixed 1.8g methyl methacrylate, 2.7g isooctyl acrylate, 2.4g octadecyl methacrylate, 1.7g hydroxypropyl methacrylate, 0.184g azobisisobutyronitrile and 3g butyl acetate After uniformity, add it to the constant pressure funnel, stir at a speed of 350 rpm, and drop it continuously within 2.5 hours, and continue the heat preservation reaction for 4 hours after the dropwise addition;

[0049] In the second step, 1.2g of 2-(perfluorooctyl)ethyl methacrylate, 0.02g of azobisisobutyronitrile and 2g of butyl acetate were mixed evenly and added to the constant pressure funnel, and then added dropwise to the first In the reaction system of the first step, the continuous dripping is completed within 1.5h, and the insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com