Supported copper-based adsorbent and preparation method thereof

An adsorbent and load-type technology, applied in separation methods, chemical instruments and methods, reagents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

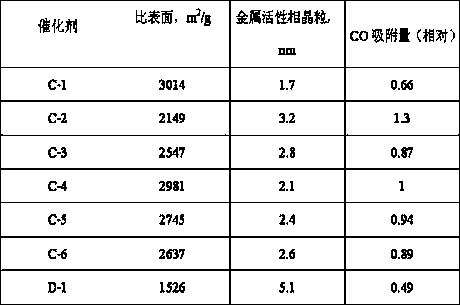

Image

Examples

Embodiment 1

[0043] Grind 100g of petroleum coke into powder, then mix it with 9.47g of sodium tetrachlorocuprate and 300g of sodium hydroxide, place it in a tube furnace, and raise the temperature to 800°C for 40 minutes under nitrogen atmosphere. After the activation, the temperature was lowered to 200 °C under a nitrogen atmosphere, and 5% (volume fraction) O 2 / Ar mixed gas treatment for 10 min.

[0044] Weigh an appropriate amount of glucose aqueous solution with a concentration of 10wt%, add it to the sample obtained above, and stir in a water bath at 50°C for 60 minutes. The obtained sample was ground into powder, weighed, mixed with deionized water at a mass ratio of 1:15, fully stirred, and then solid-liquid separated until the pH value of the filtrate was neutral, and the obtained solid sample was placed in a vacuum drying oven. Under vacuum conditions, dry at 150°C for 6 hours to obtain an adsorbent with a mass of 5% Cu in terms of elements, which is denoted as C-1.

Embodiment 2

[0046] Grind 100g of petroleum coke into powder, then mix it with 46.83g of sodium tetrachlorocuprate and 300g of potassium bicarbonate, and place it in a microwave heating furnace with a microwave frequency of 2450MHz. Under the condition of a microwave power of 0.3kw, the Under a nitrogen atmosphere, the temperature was raised to 900°C for activation for 20 minutes. After the activation, the temperature was lowered to 300 °C under a nitrogen atmosphere, and 5% (volume fraction) O 2 / Ar mixed gas treatment for 30min.

[0047] Weigh an appropriate amount of glucose aqueous solution with a concentration of 20wt%, add it to the sample obtained above, and stir in a 90°C water bath for 20min. The obtained sample was ground into powder, weighed, mixed with deionized water at a mass ratio of 1:15, fully stirred, and then solid-liquid separated until the pH value of the filtrate was neutral, and the obtained solid sample was placed in a vacuum drying oven. Under vacuum conditions, ...

Embodiment 3

[0049] Grind 100g of petroleum coke into powder, then mix it evenly with 32.56g of sodium tetrachlorocuprate and 300g of potassium hydroxide, place it in a microwave heating furnace with a microwave frequency of 2450MHz, and vacuum it under the condition that the microwave power is 0.3kw Then, the temperature was raised to 500°C and kept constant for 40 minutes, then nitrogen gas was introduced to normal pressure, and the temperature was raised to 800°C for 20 minutes under the condition of microwave power of 0.3kw for activation. After the activation, the temperature was lowered to 250 °C under a nitrogen atmosphere, and 5% (volume fraction) O 2 / Ar mixed gas treatment for 20min.

[0050] Weigh an appropriate amount of glucose aqueous solution with a concentration of 15wt%, add it to the sample obtained above, and stir in a 70°C water bath for 40min. The obtained sample was ground into powder, weighed, mixed with deionized water at a mass ratio of 1:15, fully stirred, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com