Method for producing astaxanthin through lactobacillus fermentum

A technology of astaxanthin and lactobacillus, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of strain resource limitation, achieve high antioxidant properties, mild culture conditions, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

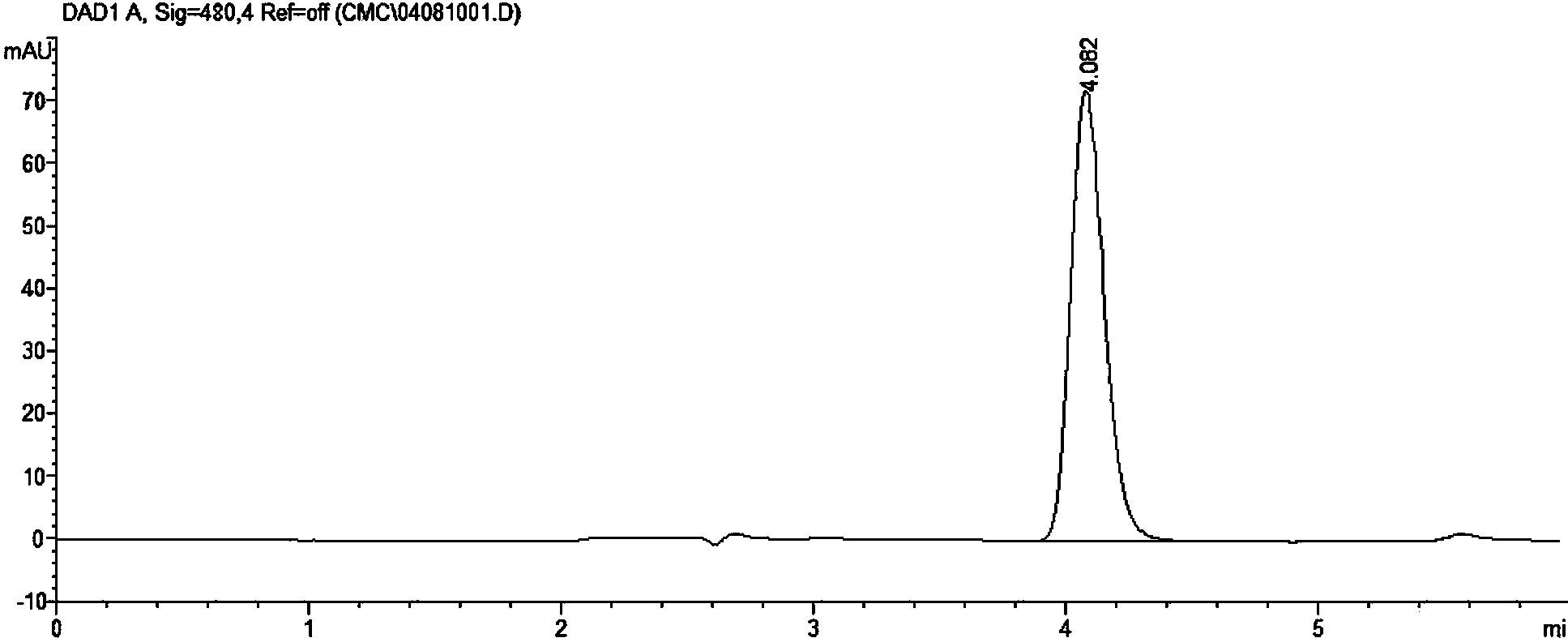

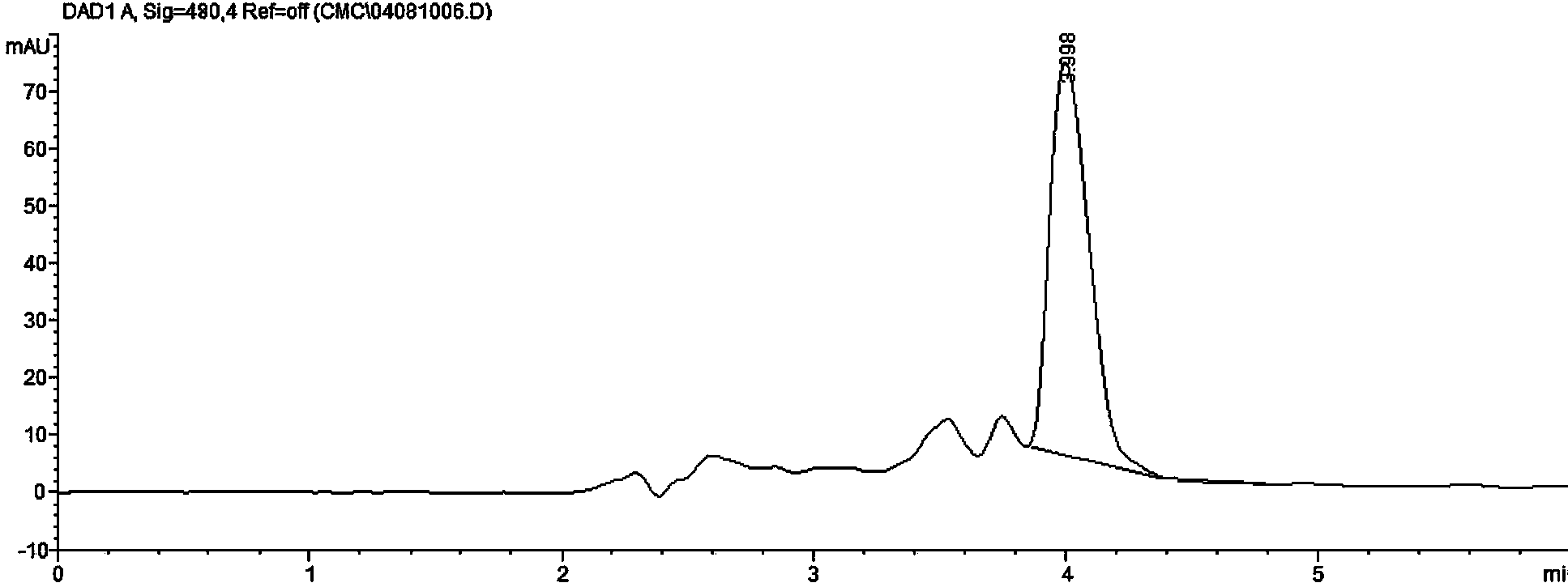

Image

Examples

Embodiment 1

[0029] S1. Fermentation culture of Lactobacillus plantarum ATCC8014: Inoculate one ring of bacterial lawn of Lactobacillus plantarum ATCC8014 into a 250mL Erlenmeyer flask containing 12.5mL of seed medium, and culture it on a shaking table at 30°C and 180r / min for 24h. Seed liquid, 5 mL of this seed liquid was inoculated in a 500 mL Erlenmeyer flask containing 45 mL of seed liquid, and cultured on a shaker at 30°C and 180 r / min for 18 hours to obtain a secondary seed liquid, and then inoculated with an inoculation amount of 6 % (v / v) Cultivate in a fermenter (10L tank contains 7L astaxanthin-producing fermentation medium) at 30°C, use a constant pH, maintain a relative dissolved oxygen content of 40-60%, and obtain a dry cell weight of 26 g / L astaxanthin Yield 598mg / L.

[0030] 60g / L sucrose, 10g / L molasses, 5g / L ammonium sulfate and 350 μL / L α-pinene contained in the astaxanthin-producing fermentation medium, 0.9 μg / L vitamin B 12 . , the pH of the medium was 7.0.

[0031]...

Embodiment 2

[0036] S1. Fermentation culture of Lactobacillus plantarum ATCC8014: Inoculate one ring of bacterial lawn of Lactobacillus plantarum ATCC8014 into a 250mL Erlenmeyer flask containing 12.5mL of seed medium, and culture it on a shaking table at 30°C and 180r / min for 24h. Seed solution, 5mL of this seed solution was inoculated into a 500mL Erlenmeyer flask containing 45mL of seed solution, cultured on a shaker at 30°C and 180r / min for 18h to obtain a secondary seed solution, and then inoculated with an inoculation amount of 8% (v / v) Cultivate in a fermenter (10L tank contains 7L astaxanthin-producing fermentation medium) at 28°C, use a constant pH, maintain a relative dissolved oxygen content of 40-60%, and obtain a dry cell weight of 28 g / L astaxanthin Yield 456mg / L.

[0037] The astaxanthin-producing fermentation medium contains 60g / L sucrose, 10g / L molasses, 5g / L ammonium sulfate and 150 μL / L α-pinene, 0.2 μg / L vitamin B 12 , the pH of the medium was 7.0.

[0038] S2. Pr...

Embodiment 3

[0041] S1. Fermentation culture of Lactobacillus plantarum ATCC8014: Inoculate one ring of bacterial lawn of Lactobacillus plantarum ATCC8014 into a 250mL Erlenmeyer flask containing 12.5mL of seed medium, and culture it on a shaking table at 30°C and 180r / min for 24h. Seed liquid, 5 mL of this seed liquid was inoculated into a 500 mL Erlenmeyer flask containing 45 mL of seed liquid, cultured on a shaker at 30°C and 180 r / min for 18 hours to obtain a secondary seed liquid, and then inoculated with 10 % (v / v) inoculum Cultivate in a fermenter (10L tank contains 7L astaxanthin-producing fermentation medium) at 26°C, use a constant pH, maintain a relative dissolved oxygen content of 40-60%, and obtain a dry cell weight of 19 g / L astaxanthin Yield 513mg / L.

[0042] 120 sucrose, 4.5 g / L urea and 500 μL / L α-pinene contained in the astaxanthin-producing fermentation medium, 0.8 μg / L vitamin B 12 , the medium pH was 6.

[0043] S2. Preparation and purification of crude pigment: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com