Novel compound building template and manufacturing method thereof

A technology of building templates and manufacturing methods, which is applied to building structures, on-site preparation of building components, construction, etc., can solve problems such as pollution, and achieve the effects of broad market prospects, smooth and clean surfaces, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

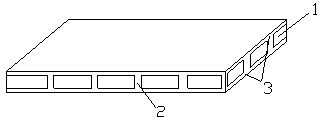

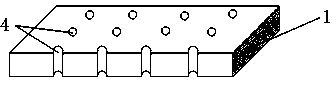

[0028] Embodiment 1: A kind of novel composite building formwork, such as figure 1 , 2 As shown, it includes a substrate 1, a plastic connecting column 2 and a plastic composite layer 3, a circular through hole 4 is opened on the substrate 1, the plastic connecting column 2 runs through the through hole 4 of the substrate 1, and the plastic composite layer 3 covers the substrate The upper and lower surfaces of 1 are closely bonded to the substrate 1, and form an integrated structure with the plastic connecting column 2; the diameter of the plastic connecting column 2 is 6 mm, the distance between two adjacent plastic connecting columns 2 is 50 mm, and the thickness of the plastic composite layer 3 is 1mm, the total thickness of the building formwork is 10mm. In this embodiment, the substrate 1 is made of wood plywood.

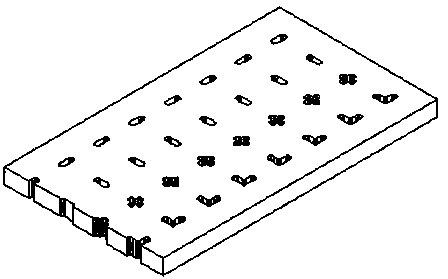

[0029] The manufacture method of above-mentioned novel composite building formwork, as image 3 shown, including the following steps:

[0030] (1) Drill th...

Embodiment 2

[0045] Embodiment 2: A kind of novel composite building template, such as figure 1 , 2 As shown, it includes a substrate 1, a plastic connecting column 2 and a plastic composite layer 3, a circular through hole 4 is opened on the substrate 1, the plastic connecting column 2 runs through the through hole 4 of the substrate 1, and the plastic composite layer 3 covers the substrate The upper and lower surfaces of 1 are closely attached to the substrate 1, and form an integrated structure with the plastic column 2; specifically, the diameter of the plastic connecting column 2 is 8 mm, and the lateral distance between two adjacent plastic columns 2 is 10 mm, and the vertical distance is 10 mm. The thickness of the plastic composite layer 3 is 2.5 mm, and the total thickness of the building formwork is 25 mm. In this embodiment, the substrate 1 is made of a moisture-proof paper honeycomb board, the honeycomb paper core is 350g kraft paper, and the hole diameter is 8mm.

[0046] T...

Embodiment 3

[0062] Embodiment 3: roughly the same as Embodiment 1, the difference is that the through hole is a cross-shaped through hole with a width of 8 mm, the distance between two adjacent plastic columns 2 is 100 mm, and the thickness of the plastic composite layer 3 is 6 mm. The thickness is 30mm, the substrate 1 is made of sawdust board, and the plastic slurry is made of micro-foamed PVC plastic. The formulation of the plastic slurry is shown in Table 3. In the manufacturing method, the temperature of the plastic slurry in step (1) is raised to 120-160°C. The maximum temperature of PVC plastic should not exceed 160°C for a long time, otherwise it will burn. Step (4) Cool in the water tank for 2 minutes. The service life of this embodiment can reach 45 times.

[0063] Table 3 Formula 3 (by mass parts)

[0064] PVC 80 Regenerated PVC (grade 1) 20

[0065] CPE 5 ACR 2

[0066] DOP 2 epoxidized soybean oil 2

[0067] Zn530 6 PA60 1

[0068] Stearic acid 0.2 Paraffin wax 0.3

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Carrying capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com