LED (Light-Emitting Diode) lamp tube with large light flux and large light-emitting angle and manufacturing method thereof

A technology of LED tube and light emitting angle, applied in the field of LED tube, can solve the problems of increasing the power consumption of fluorescent tube, high manufacturing cost, increasing possibility of failure, etc., and achieve the effect of improving system reliability and system repair ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] The specific implementation method comprises the following steps:

[0020] a. Put the COMMB-LED light source mold strip completed by solid crystal, wire bonding, dispensing and external lead electrode tinning into the serial-parallel tooling, and perform serial-parallel soldering connection;

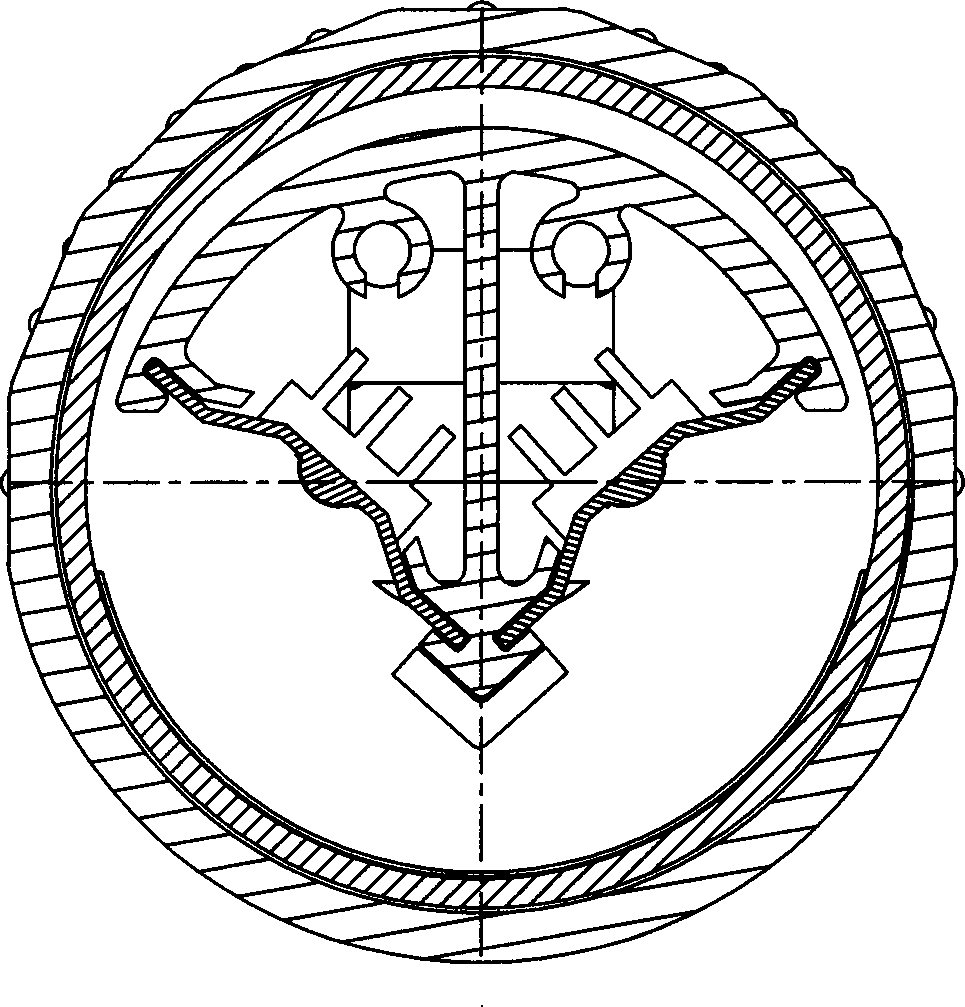

[0021] b. Use the COMMB-LED light source mold strip to install it into the COMMB-LED light source mold strip embedding groove on the two symmetrical slopes of the heat-conducting and heat-transfer aluminum profile of the V-shaped structure;

[0022] c. Install the diffusion film axially into the glass tube along the inner wall of the light-emitting end of the glass tube;

[0023] d. Put the combination of the V-shaped heat-dissipating heat-transfer aluminum profile and the COMMB-LED light source assembly into the glass tube;

[0024] e. After injecting flexible hot-melt colloid into the rubber ring groove of the insulating connecting sleeve on the supporting part along the circum...

specific Embodiment

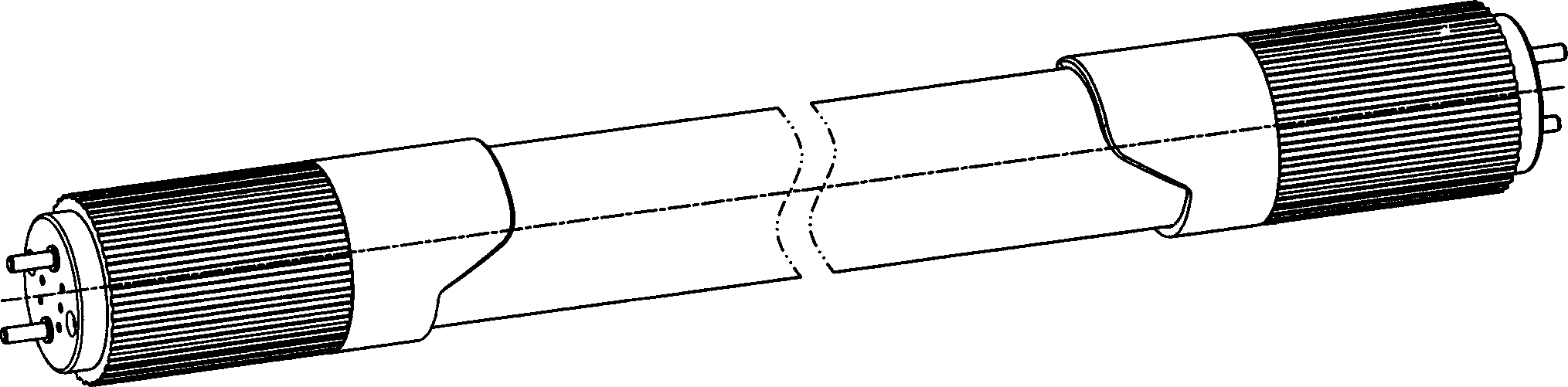

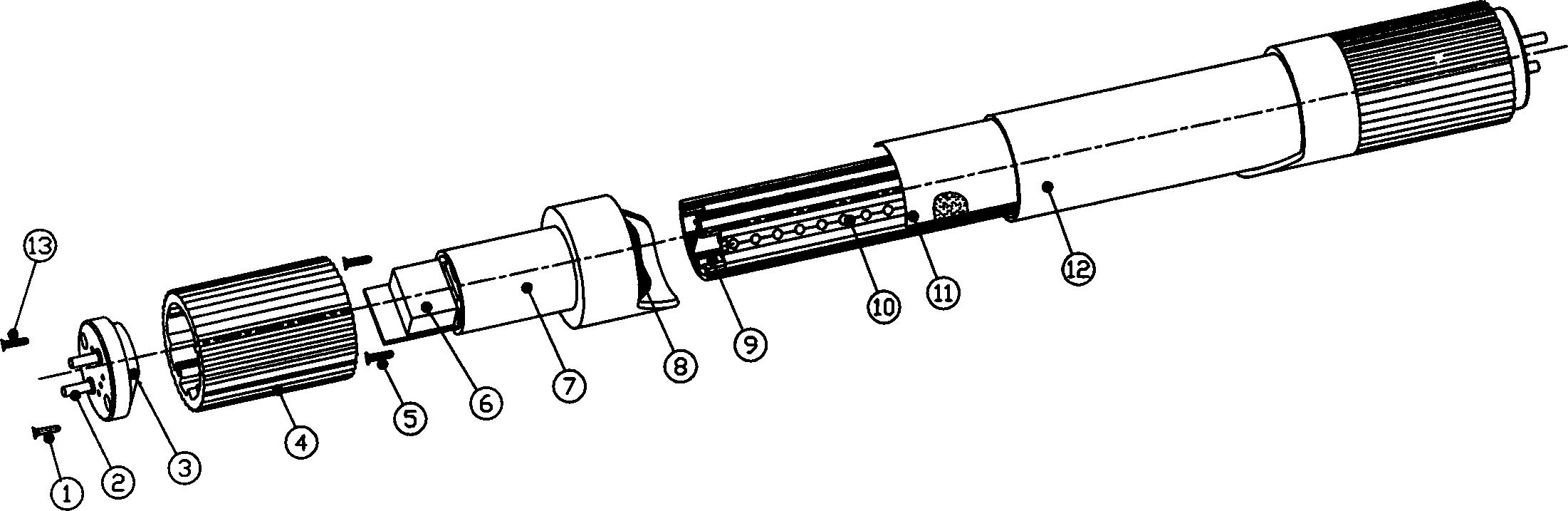

[0032] like figure 1 , 2 As shown, a LED lamp tube with large luminous flux and large light output angle includes: 1. End cap locking screws for connecting the external copper post wiring cover of the LED fluorescent lamp tube with the aluminum shell cap; 2. External copper post, which is introduced Realize the rigid connection between the lamp tube and the lamp frame at the same time as the mains; 3. The external copper column connection cover is used as the support of the external copper column in the LED fluorescent tube and the axial cover of the lamp tube; 4. The aluminum shell cover head, Used as the heat sink of the constant current power supply of the COMMB-LED light source component and the connecting piece of the plastic transition sleeve; 5. The set screw of the transition sleeve is used to complete the rigidity of the plastic transition sleeve, the aluminum shell cover head and the external copper column wiring cover Connection; 6. Constant current power supply, u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Beam angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com