Metal double-hydroxide/molybdenum disulfide nano-composite material and preparation method and application thereof

A technology of nanocomposite materials and double hydroxides, applied in the field of nanomaterials, can solve problems such as no reports, and achieve the effects of simple steps, large surface area, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

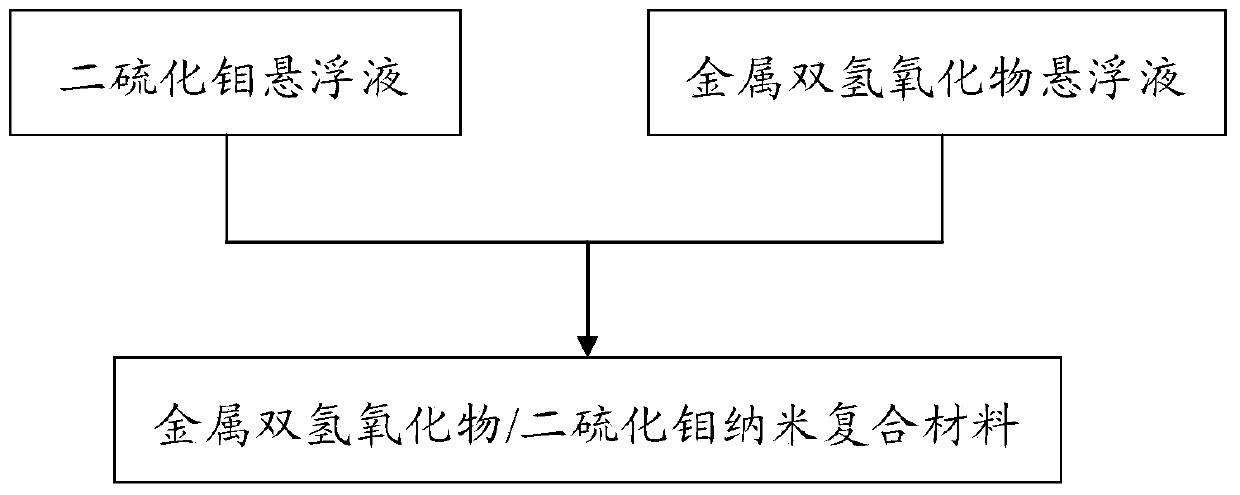

Method used

Image

Examples

Embodiment 1

[0050] 1) Ultrasonic hydrolysis of 0.5 g of layered molybdenum disulfide after lithium ion intercalation in deionized water for 2 hours to prepare the exfoliated molybdenum disulfide suspension;

[0051] 2) Add 0.3mmol Ni(NO 3 ) 2 ·6H 2 O and 0.1mmolFe(NO 3 ) 3 9H 2 O was dissolved in 200 ml of deionized water, stirred and mixed, and 2.0 mol / liter of sodium hydroxide solution was added dropwise under the protection of nitrogen to adjust the pH of the reaction system to 10, and then stirred and reacted at 100°C for 24 hours, the precipitate in the solution After centrifugation and washing, take 0.1g and redisperse in deionized water to obtain metal double hydroxide (NiFe-LDH) suspension;

[0052] 3) Mix the molybdenum disulfide suspension obtained in 1) with the NiFe-LDH suspension obtained in 2), and stir and react at 30°C for 4 hours to obtain NiFe-LDH / disulfide with a NiFe-LDH content of 16.7%. Molybdenum nanocomposites.

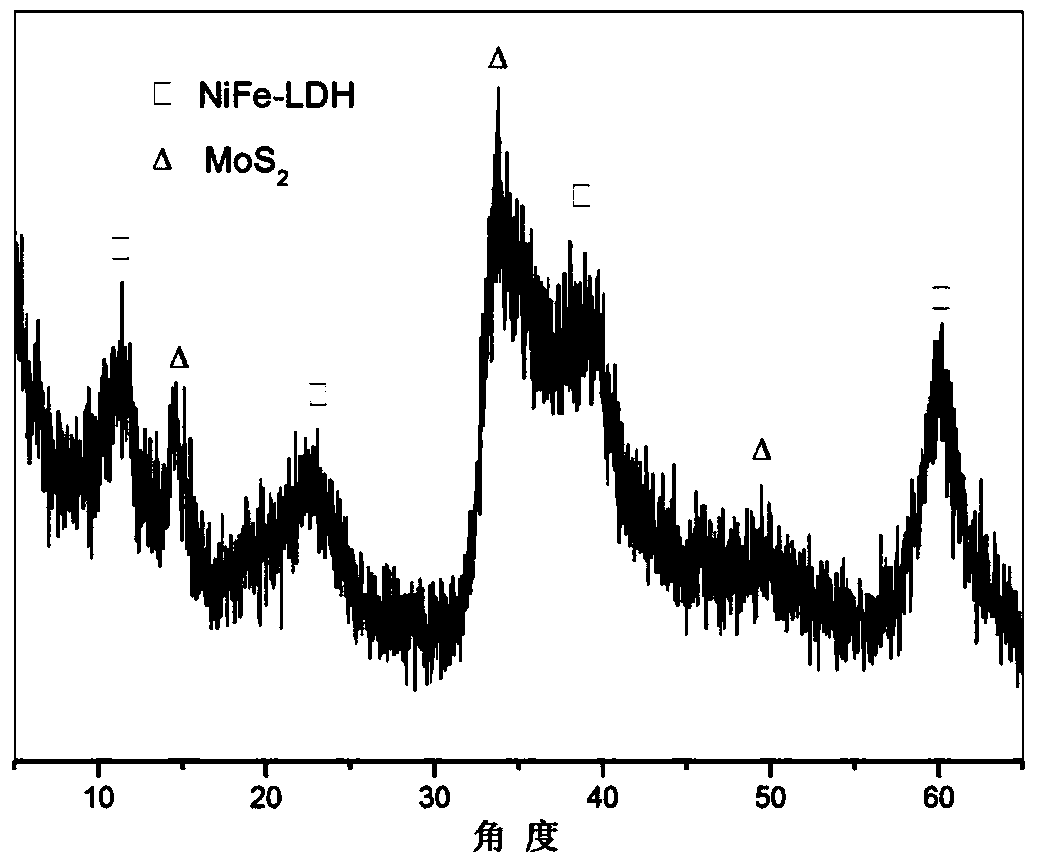

[0053] Such as figure 2 As shown, the diffr...

Embodiment 2

[0056] Other conditions are with embodiment 1, with Ni(NO 3 ) 2 ·6H 2 O to Mg(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O to Al(NO 3 ) 3 9H 2 O, 0.125 g was re-dispersed in deionized water to obtain a metal double hydroxide (MgAl-LDH) suspension in step 2), and finally a MgAl-LDH / molybdenum disulfide nanocomposite material with a MgAl-LDH content of 20% was obtained.

[0057] Such as Figure 4 As shown, the diffraction peaks of molybdenum disulfide and MgAl-LDH appeared in the XRD of the composite material at the same time.

[0058] Such as Figure 5 As shown, A refers to the MgAl-LDH sheet, B refers to the molybdenum disulfide nanosheet, and the MgAl-LDH sheet is evenly distributed on the molybdenum disulfide sheet to form a MgAl-LDH / molybdenum disulfide nanocomposites.

Embodiment 3

[0060] Other conditions are with embodiment 1, Ni(NO 3 ) 2 ·6H 2 O to Co(NO 3 ) 2 ·6H 2 O, step 2) 0.25 g was redispersed in deionized water to obtain a metal double hydroxide (CoFe-LDH) suspension, and finally a CoFe-LDH / MoS2 nanocomposite with a CoFe-LDH content of 33.3% was obtained.

[0061] The obtained CoFe-LDH / molybdenum disulfide nanocomposite material was tested by X-ray diffraction and transmission electron microscopy. The results showed that the XRD of the composite material showed obvious diffraction peaks of molybdenum disulfide and CoFe-LDH at the same time. The transmission electron micrograph of the composite material shows that the sheets of CoFe-LDH are uniformly distributed on the sheets of molybdenum disulfide, forming a CoFe-LDH / molybdenum disulfide nanocomposite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com