Gold nanoparticle-silver nano-semisphere array as well as preparation method and application thereof

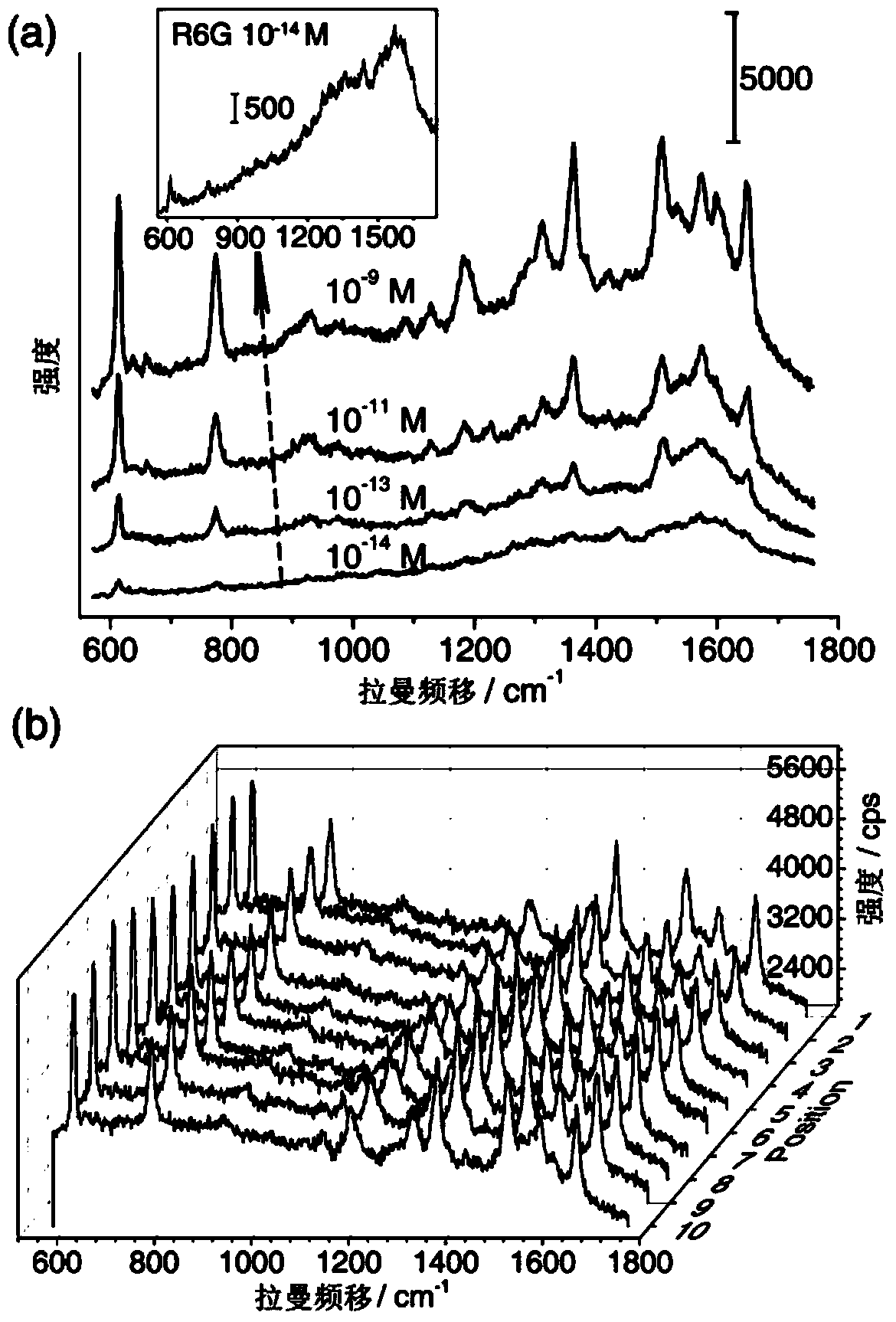

A gold nanoparticle, silver nanoparticle technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as the inability to obtain interstitial ordered arrays, and achieve structural stability and preparation methods. effect of science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The concrete steps of preparation are:

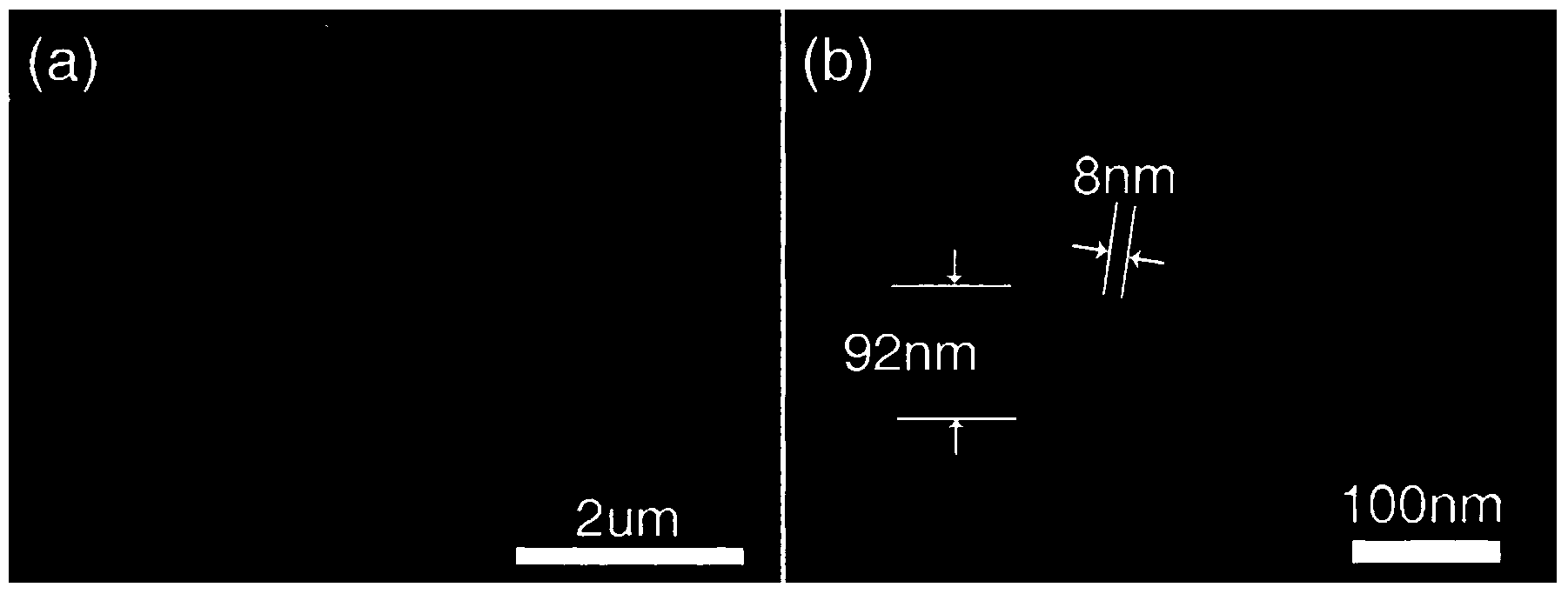

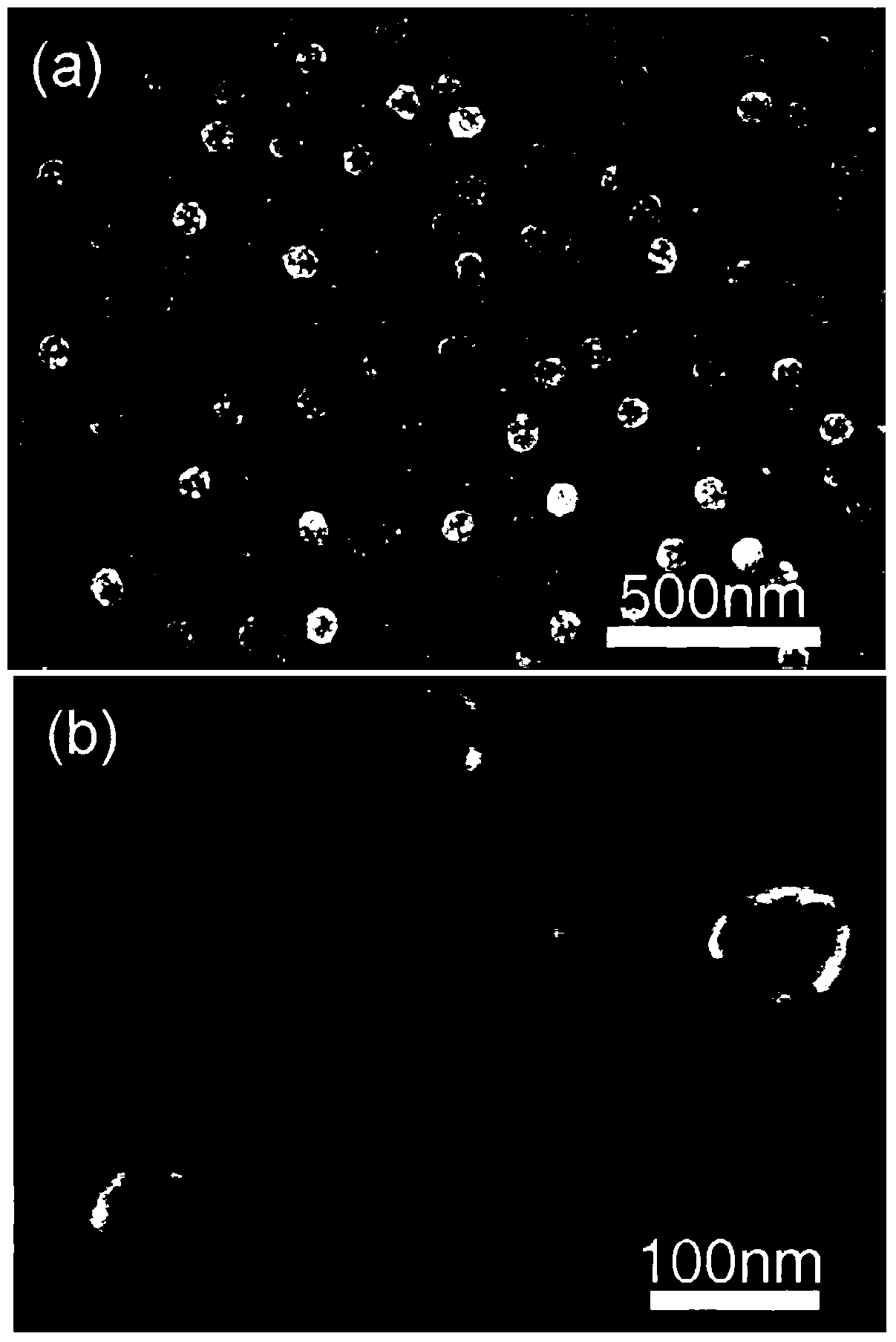

[0044] Step 1. First, expand the through-hole alumina template with a hole diameter of 50nm and a hole center distance of 100nm. Soak the through-hole alumina template in a phosphoric acid solution with a temperature of 35°C and a concentration of 4wt%. After 18 minutes, a through-hole alumina template with a pore diameter of 85 nm was obtained. Then use an ion sputtering device to plate a silver film on one side of the through-hole alumina template; wherein, the ion sputtering current is 4mA and the time is 20min when the silver film is plated, so that one side is covered with a silver film and silver nanohemispheres are agglomerated in the holes. alumina template.

[0045] In step 2, the aluminum oxide template covered with silver film on one side and silver nano-hemispheres agglomerated in the holes is heated to 115° C., and then the surface of the silver film is coated with paraffin wax. Then, the substrate is adhered and f...

Embodiment 2

[0048] The concrete steps of preparation are:

[0049] Step 1. First, expand the through-hole alumina template with a hole diameter of 55nm and a hole center distance of 100nm, that is, place the through-hole alumina template in a phosphoric acid solution with a temperature of 38°C and a concentration of 4.5wt%. Soak for 19 minutes to obtain a through-hole alumina template with a pore diameter of 88 nm. Then use an ion sputtering device to plate a silver film on one side of the through-hole alumina template; wherein, the ion sputtering current is 4.5mA and the time is 20min when the silver film is plated. Alumina template for hemispheres.

[0050] In step 2, the aluminum oxide template covered with silver film on one side and silver nano-hemispheres agglomerated in the holes is heated to 120° C., and then paraffin wax is coated on the surface of the silver film. Then, the substrate is adhered and fixed on the surface of the silver film, and after cooling, an aluminum oxide t...

Embodiment 3

[0053] The concrete steps of preparation are:

[0054] Step 1. First, expand the through-hole alumina template with a hole diameter of 60nm and a hole center distance of 100nm. Soak the through-hole alumina template in a phosphoric acid solution with a temperature of 40°C and a concentration of 5wt%. After 20 minutes, a through-hole alumina template with a pore diameter of 90 nm was obtained. Then use an ion sputtering device to plate a silver film on one side of the through-hole alumina template; wherein, when the silver film is plated, the current of ion sputtering is 5mA, and the time is 20min, so that one side is covered with a silver film and silver nanohemispheres are agglomerated in the holes. alumina template.

[0055] In step 2, the aluminum oxide template covered with silver film on one side and silver nano-hemispheres aggregated in the holes is heated to 125° C., and then the surface of the silver film is coated with paraffin wax. Then, the substrate is adhered an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com