Inorganic flame retardant and preparation method thereof

An inorganic flame retardant and formulation technology, applied in the field of flame retardants, can solve the problems of high production cost, unfavorable environmental protection, and a large amount of black smoke, and achieve the effects of good thermal stability, reduced density, and improved tinting strength

Inactive Publication Date: 2013-12-18

吴丛科

View PDF1 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In recent years, due to the wide application of interior decoration materials, the fire and flame retardant properties of synthetic materials are increasingly important to building safety. Among various inorganic flame retardants, magnesium aluminum hydrotalcite has good thermal stability and flame retardant properties. It is a high-efficiency, non-toxic, low-smoke high-quality flame-retardant material, but the preparation cost is high. The antimony oxide flame retardant can be combined with the halogen contained in the synthetic material, or the cold dew used in conjunction with it. The compound produces a great synergistic flame retardant effect and is a highly efficient flame retardant synergist, but it will produce a lot of black smoke when burning, which is not conducive to environmental protection

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0028] The second embodiment of the present invention is basically the same as the first embodiment, the difference is that the modifying agent in the formula is 403 in the KBE coupling agent series, and the process steps are the same as the first embodiment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Login to View More

Abstract

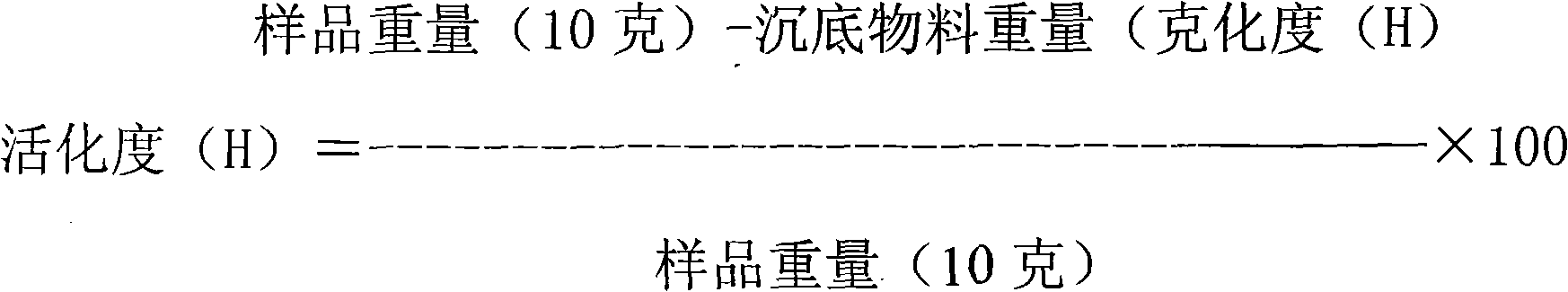

The invention discloses an inorganic flame retardant and a preparation method thereof. The inorganic flame retardant has the characteristic that the components of the inorganic flame retardant consist of ultrafine magnesium silicate, aluminum hydroxide and a modifying agent. The preparation method of the inorganic flame retardant comprises the following steps: material selection, material pretreatment, crushing treatment, modifying agent selection and treatment, and modifying treatment, wherein the modifying treatment is as follows: adding the product particles into a modifying machine; meanwhile, heating up the modifying machine, so that the materials in the modifying machine are heated up to 100 DEG C; dropwise adding a coupling agent after 10 minutes, wherein the adding amount of the coupling agent is 1.2%, and the temperature is kept at 100 DEG C for 30 minutes when the coupling agent is added. The inorganic flame retardant disclosed by the invention is not only used for improving tension strength, shearing strength, flexural strength and pressure strength of the product, but also is high in whiteness, uniform in grain size and strong in dispersity. Meanwhile, the inorganic flame retardant further can be used for improving CTI (Computer Telephony Integration) indexes, is not only good in thermal stability and invariant in color, but also is capable of improving the tinting strength of the material.

Description

technical field [0001] The invention relates to a flame retardant, mainly an inorganic flame retardant and a preparation method thereof. Background technique [0002] Flame retardant is one of the main components of fireproof coatings for steel components, fireproof fillers for plastic materials, and fireproof fillers for cable insulation layers. Its consumption is increasing rapidly with the improvement of the country's industrialization level and people's living standards. In recent years, due to the wide application of interior decoration materials, the fire and flame retardant properties of synthetic materials are increasingly important to building safety. Among various inorganic flame retardants, magnesium aluminum hydrotalcite has good thermal stability and flame retardant properties. It is a high-efficiency, non-toxic, low-smoke high-quality flame-retardant material, but the preparation cost is high. The antimony oxide flame retardant can be combined with the halogen ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08K9/06C08K3/34C08K3/22C09C1/40C09C3/12

Inventor 吴丛科

Owner 吴丛科

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com