Resin composition, pre-preg, and metal foil clad laminate

A resin composition, epoxy resin technology, applied in metal layered products, layered products, thin material processing and other directions, can solve the problems of decreased reflectivity, low heat resistance of laminates, discoloration of substrate surfaces, etc. Less drop in reflectance, high industrial applicability, high heat resistance and high light reflectance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1)

[0113] Into a 300ml five-necked glass round bottom flask equipped with stainless steel half-moon stirring blades, nitrogen introduction tube, Dean-Stark trap equipped with condenser, thermometer, and glass end cap, each 100g1 ,2,4-Cyclohexanetricarboxylic acid-1,2-anhydride (H-TMAn, manufactured by Mitsubishi Gas Chemical Co., Ltd.), 100g of methyl ethyl ketone, heated with a mantle heater, and heated the reaction system in about 10 minutes The temperature was raised to 80°C, stirred for 60 minutes to form a uniform solution, and air-cooled to 50°C for about 10 minutes to obtain a solution with a solid content concentration of 50% by mass.

Embodiment 1)

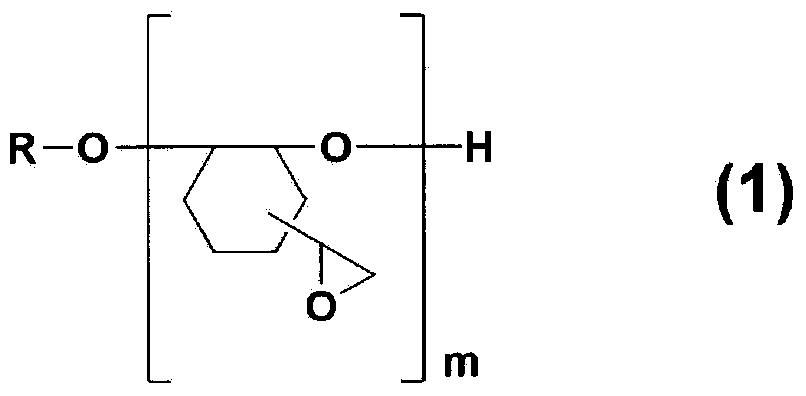

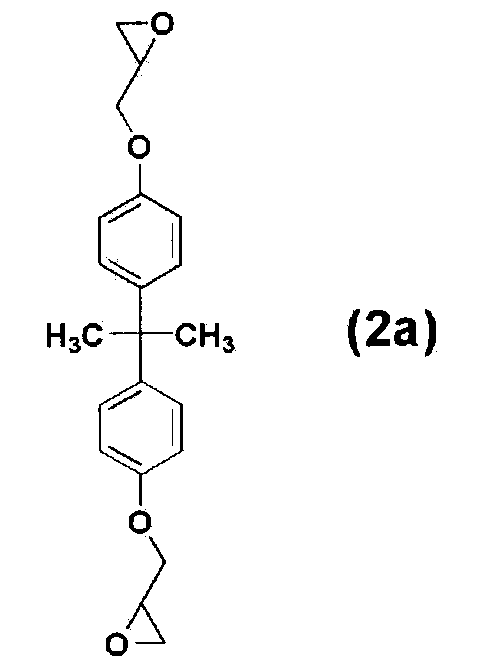

[0115] Stir and mix 24 parts by mass of the solution obtained in Preparation Example 1 with a homomixer (12 parts by mass based on 1,2,4-cyclohexanetricarboxylic acid-1,2-anhydride (H-TMAn)), as The epoxy resin having a bisphenol A skeleton represented by the following formula (3) is an epoxy resin having a bisphenol A skeleton (EP-1001, manufactured by Japan Epoxy Resins Co., Ltd.) 27 parts by mass, as an alicyclic formula 2,2-bis(hydroxymethyl)-1-butanol 1,2-epoxy-4-(2-oxiranyl) cyclohexane adduct of epoxy resin (EHPE-3150, DAICELCHEMICAL Made by INDUSTRIES, LTD.) 61 parts by mass, titanium dioxide (CR90 (with respect to the total amount of 100 parts by mass, containing 1 to 5 parts by mass of SiO) 2 And 1~3 parts by mass of Al 2 O 3 . ), ISHIHARASANGYO KAISHA, LTD.) 75 parts by mass, and 1.75 parts by mass of the dispersant (BYK-W903, manufactured by BYK Japan K.K.) to obtain a varnish.

[0116] The varnish was diluted with methyl ethyl ketone in equal times on a mass basis, ...

Embodiment 2)

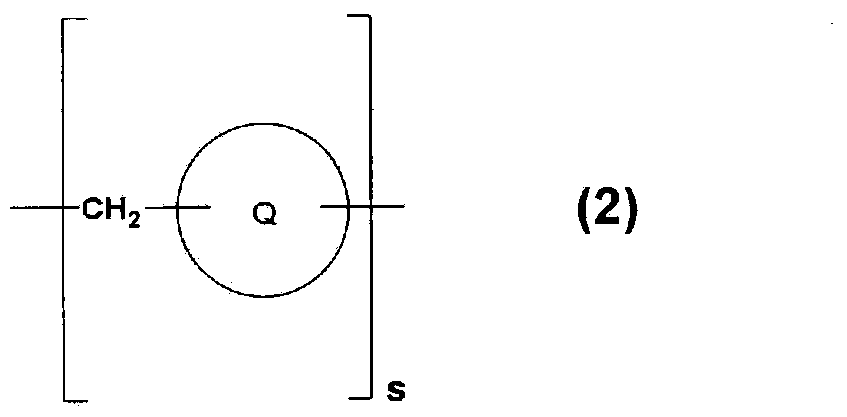

[0121] Stir and mix 28 parts by mass of the solution obtained in Preparation Example 1 with a homomixer (14 parts by mass based on 1,2,4-cyclohexanetricarboxylic acid-1,2-acid anhydride (H-TMAn)), as Novolac type epoxy resin having a bisphenol A skeleton represented by the following formula (4): 12 parts by mass of an epoxy resin having a bisphenol A skeleton (N-890, manufactured by DICCORPORATION), alicyclic epoxy resin ( EHPE-3150) 74 parts by mass, 75 parts by mass of titanium dioxide (CR90), and 1.75 parts by mass of dispersant (BYK-W903) to obtain a varnish.

[0122] Except for using the varnish, the same procedure as in Example 1 was carried out to obtain a prepreg and a double-sided copper-clad laminate with a thickness of 0.2 mm.

[0123]

[0124] (In the formula, m is a positive integer.)

[0125] Among them, in the skeleton represented by the general formula (4), the part formed by m repeating units is the same as the skeleton represented by the above general formula (2), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com