Preparation method of cottonseed protein

A cottonseed protein and cottonseed meal technology, applied in the field of cottonseed processing, can solve the problems of less than 35% protein extraction rate, high production cost, difficult enzymatic hydrolysis process control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of cottonseed protein is as follows:

[0031] (1) Crushing the raw material of cottonseed meal;

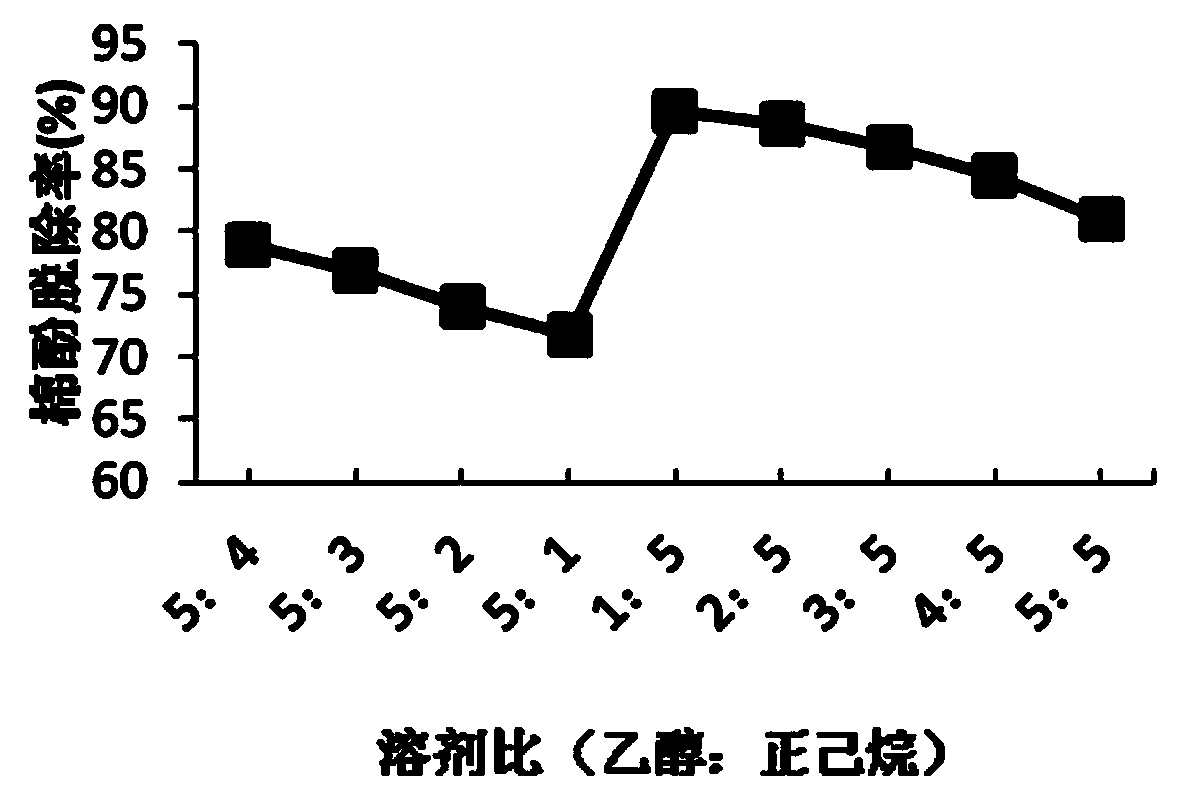

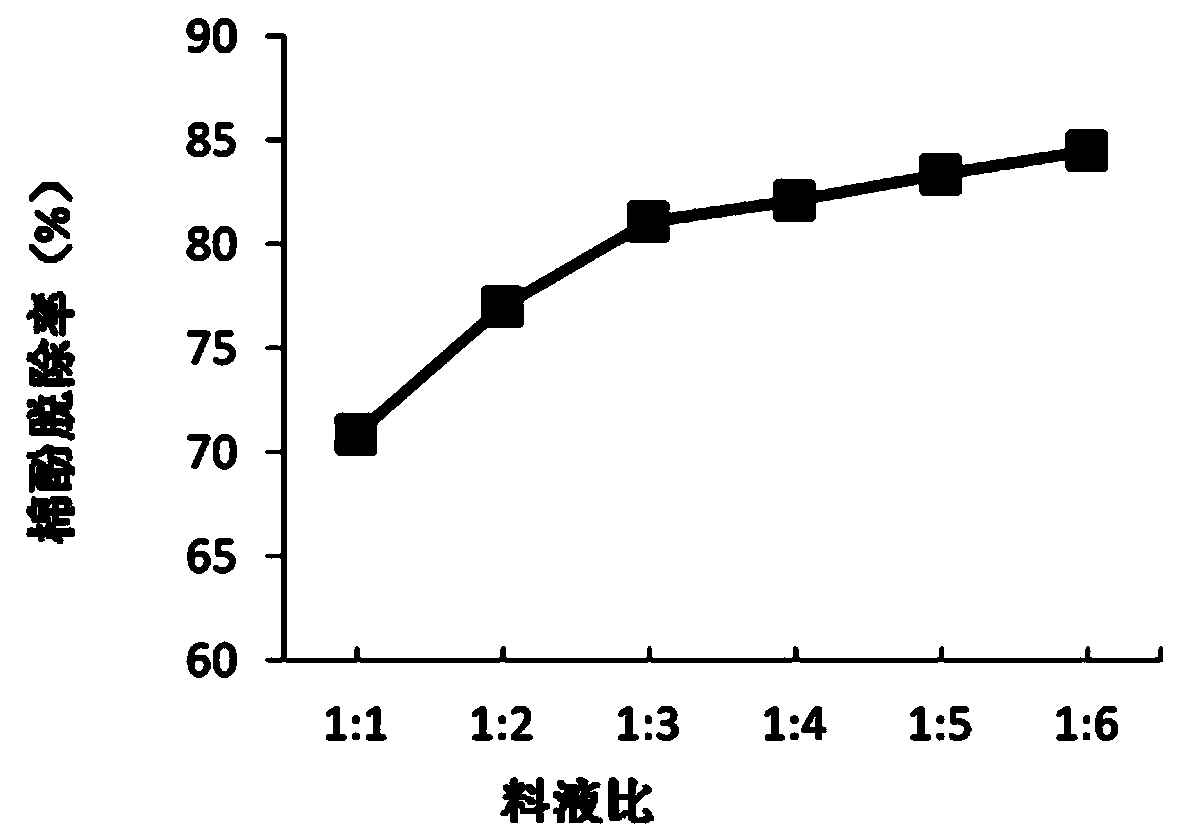

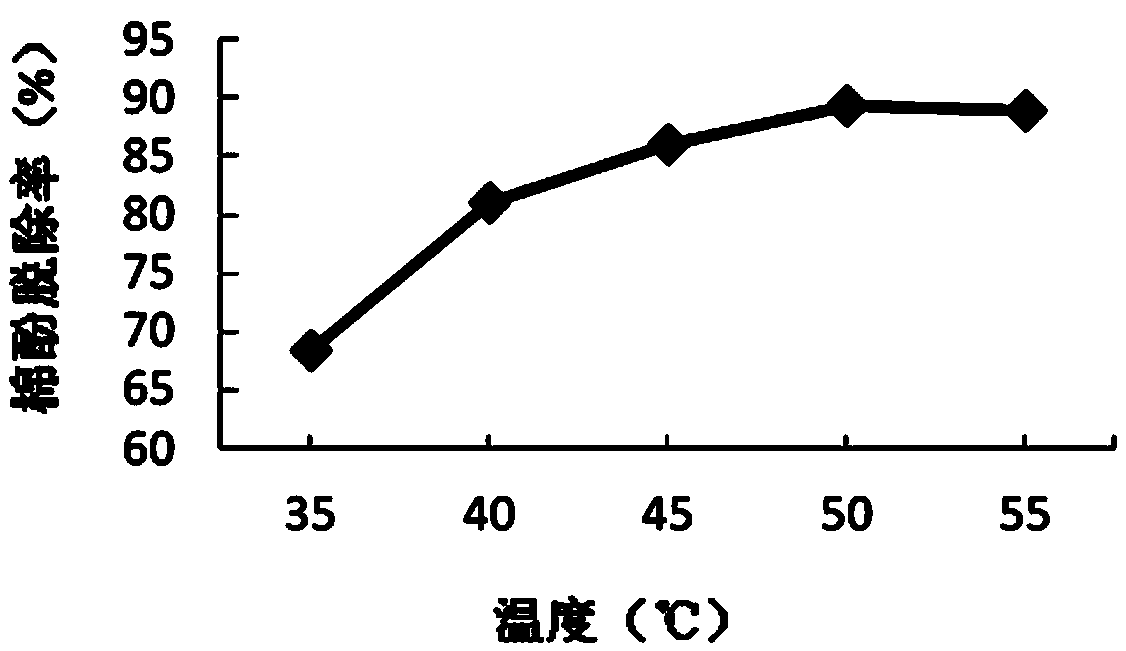

[0032] (2) Extract the crushed cottonseed meal with a mixed solvent of ethanol and n-hexane to remove gossypol from the cottonseed meal;

[0033] (3) After the dephenolized cottonseed meal is separated from the mixed solvent, the dephenolized cottonseed meal is obtained;

[0034] (4) Add water to the dephenolized cottonseed meal, then add sodium hydroxide and sodium sulfite to extract cottonseed protein;

[0035] (5) After the dephenolized cottonseed meal is leached, the extract solution is separated, acid is added to adjust the pH of the extract solution to 4-6, acid precipitation, and the precipitation is cottonseed protein.

[0036] The method of the present invention has no special restrictions on the cottonseed meal, which can be the residue after the oil is extracted from the cottonseed by pressing, or the residue after the oil is extracted by...

Embodiment 1

[0072] (1) Pulverize the cottonseed meal;

[0073] (2) The pulverized cottonseed meal is leached with a mixed solvent of ethanol and n-hexane to remove gossypol in the cottonseed meal. The liquid ratio is 1:4 (w / v, g / ml), the extraction temperature is 50°C, and the extraction time is 1 hour, the removal rate of gossypol is 89.60%, and the free gossypol (FG) in dephenolized cottonseed meal is ≤400mg / kg;

[0074] (3) After the dephenolized cottonseed meal is separated from the mixed solvent, the dephenolized cottonseed meal is obtained;

[0075] (4) Add water to the dephenolized cottonseed meal, and then add sodium hydroxide and sodium sulfite to extract cottonseed protein. The ratio of solid to liquid between the dephenolized cottonseed meal and the infusion solution is 1:15, the temperature is 60°C, and the extraction time is 1 hour. The mass ratio of sodium hydroxide and sodium sulfite in the soaking liquid is 1:1, and the total concentration of sodium hydroxide and sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com