Preparation method of spinning electrode used for testing electrocardiosignal

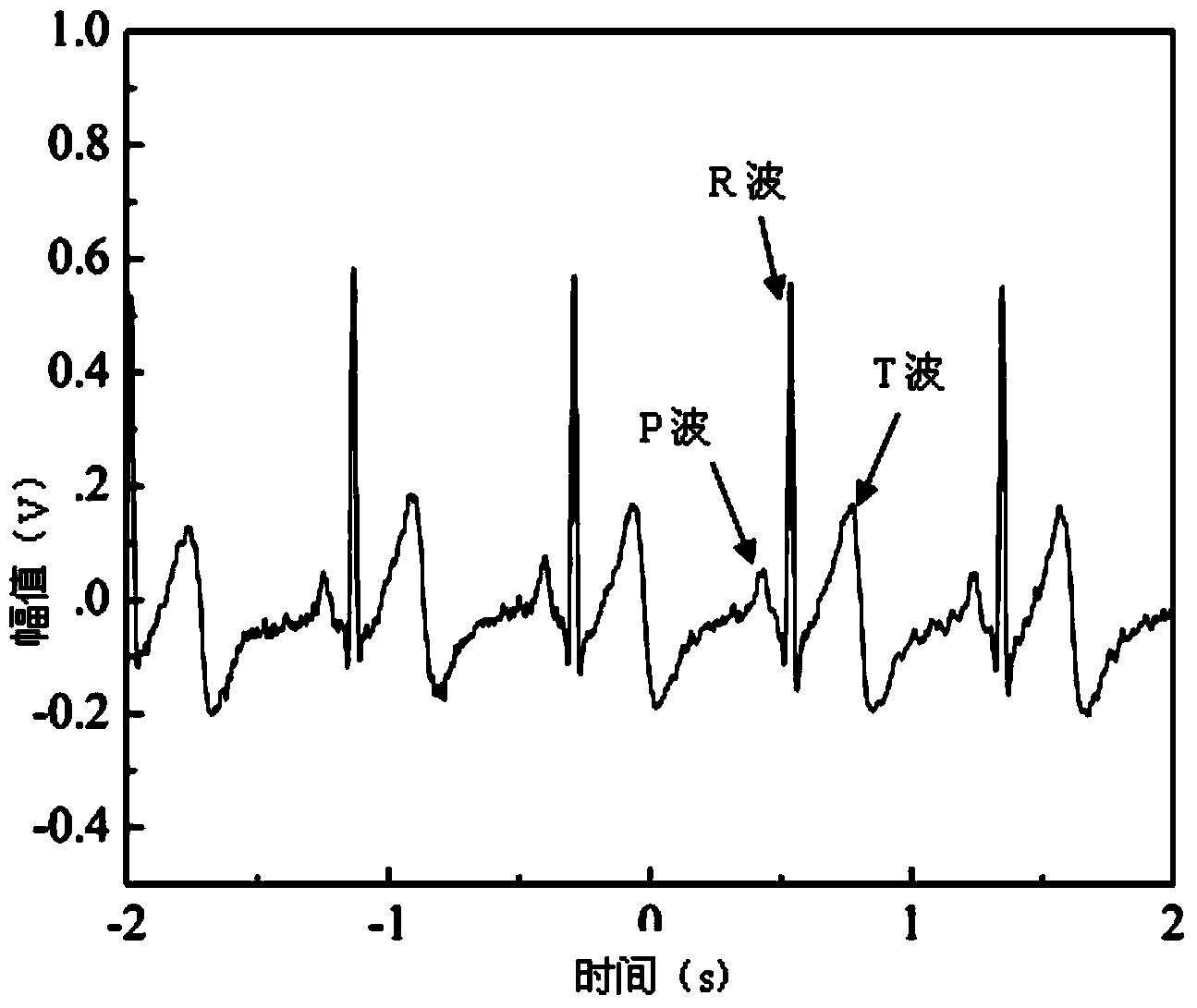

A technology for textile electrodes and ECG signals, which is applied in the field of preparation of textile electrodes, can solve problems affecting the stability of ECG signals, easy to fall off, and high requirements, so as to avoid ECG signal instability, simple manufacturing process, and good flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

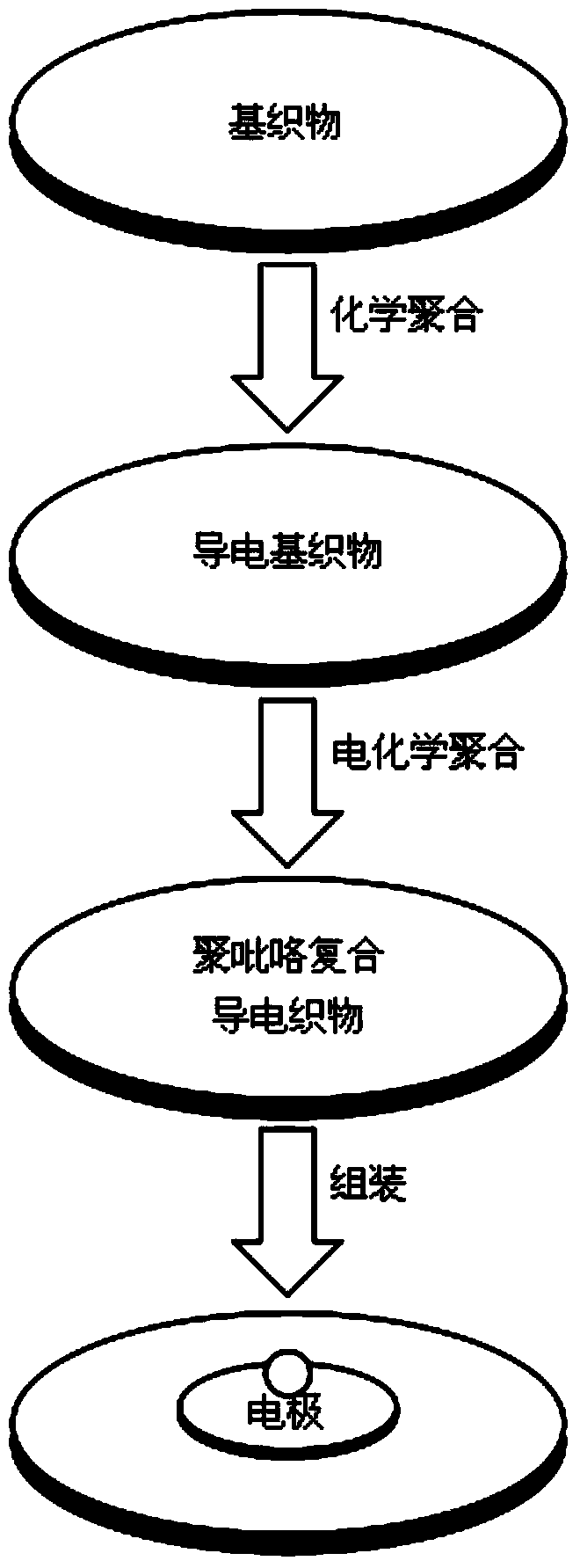

[0033] Choose cotton woven fabric (gram weight 91.73g / m 2 ) as the base fabric. The preparation steps of textile electrodes include two steps of chemical polymerization and electrochemical polymerization, namely:

[0034] Chemical polymerization: Add sodium dodecylbenzenecyclonate to distilled water to obtain 0.009mol / L solution A, add ammonium persulfate to solution A to make the concentration 0.02mol / L, obtain solution B, and immerse the base fabric in solution B , the bath ratio is 1:150, and the infiltration solution C is obtained, and the solution C is soaked in an ice-water bath at 0-4°C for 30 minutes with slight stirring with a magnet, and then pyrrole monomer is added to the solution C so that the concentration is 0.04mol / L, to obtain the reaction solution D, react D (including the base fabric) in an ice-water bath at 0-4°C for 2 hours, take out the base fabric, rinse with deionized water until there is no black residue in the water, put the washed base fabric Bake...

Embodiment 2

[0037] Choose cotton knitted fabric (weight: 194.98g / m 2 ) as the base fabric. The preparation steps of textile electrodes include two steps of chemical polymerization and electrochemical polymerization, namely:

[0038] Chemical polymerization: Add sodium dodecylbenzenecyclonate to distilled water to obtain 0.009mol / L solution A, add ammonium persulfate to solution A to make the concentration 0.02mol / L, obtain solution B, and immerse the base fabric in solution B , the bath ratio is 1:150, and the infiltration solution C is obtained, and the solution C is soaked in an ice-water bath at 0-4°C for 30 minutes with slight stirring with a magnet, and then pyrrole monomer is added to the solution C so that the concentration is 0.04mol / L, to obtain the reaction solution D, react D (including the base fabric) in an ice-water bath at 0-4°C for 2 hours, take out the base fabric, rinse with deionized water until there is no black residue in the water, put the washed base fabric Bake ...

Embodiment 3

[0042] Choose cotton non-woven fabric (weight: 174.26g / m 2 ) as the base fabric. The preparation steps of textile electrodes include two steps of chemical polymerization and electrochemical polymerization, namely:

[0043] Chemical polymerization: Add sodium dodecylbenzenecyclonate to distilled water to obtain 0.009mol / L solution A, add ammonium persulfate to solution A to make the concentration 0.02mol / L, obtain solution B, and immerse the base fabric in solution B , the bath ratio is 1:150, to obtain the infiltration solution C, let the solution C in the ice-water bath at 0-4 °C and infiltrate it for 20 minutes with gentle stirring with a magnet, and then add pyrrole monomer to the solution C, so that the concentration is 0.04mol / L, to obtain the reaction solution D, react D (including the base fabric) in an ice-water bath at 0-4°C for 1 hour, take out the base fabric, rinse with deionized water until there is no black residue in the water, put the washed base fabric Bake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com