Solar monocrystalline silicon cleaning solution and cleaning method

A monocrystalline silicon wafer and solar energy technology, which is applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problem of not meeting the technical requirements of cells, affecting the yield and product quality, and reducing the battery capacity. In order to achieve the effect of reducing organic matter and metal ion residues, improving market competitiveness and improving surface state structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

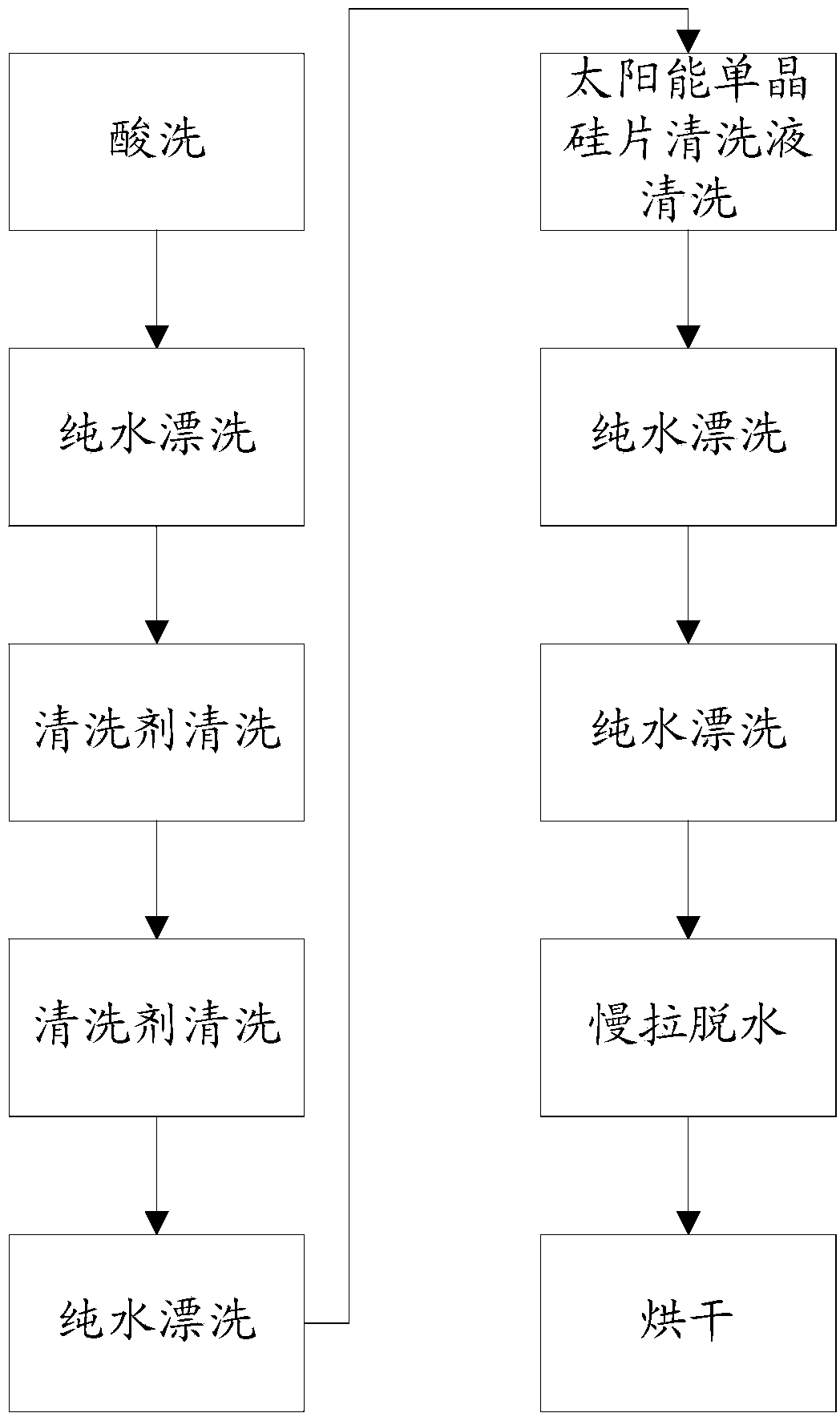

[0049] 1) A batch of 200 monocrystalline silicon wafers is ultrasonically cleaned in the pickling tank, pure water rinsing tank, cleaning agent washing tank, cleaning agent washing tank and pure water rinsing tank. The cleaning time in each tank is 240s.

[0050] 2) Immerse the batch of monocrystalline silicon wafers in the chemical tank containing solar single crystal silicon wafer cleaning solution for cleaning, turn on the ultrasound, set the temperature of the chemical tank to 35°C, and the cleaning time is 240s.

[0051] Each component and mass percentage in this solar single crystal silicon wafer cleaning liquid are respectively: hydrogen peroxide adopts mass fraction to be 30% hydrogen peroxide analytical pure reagent, and mass percentage is 3%; Potassium hydroxide adopts analytical pure reagent, mass percentage is 0.1%; the balance is pure water, and the resistance is 15 megohms.

[0052] 3) The batch of monocrystalline silicon wafers cleaned in step 2) are rinsed twi...

Embodiment 2

[0054] 1) A batch of 225 monocrystalline silicon wafers is ultrasonically cleaned in the pickling tank, pure water rinsing tank, cleaning agent washing tank, cleaning agent washing tank and pure water rinsing tank. The cleaning time in each tank is 300s.

[0055] 2) Immerse the batch of monocrystalline silicon wafers in the chemical tank containing solar single crystal silicon wafer cleaning solution for cleaning, turn on the ultrasound, set the temperature of the chemical tank to 45°C, and the cleaning time is 300s.

[0056] Each component and mass percent in this solar single crystal silicon wafer cleaning solution are respectively: hydrogen peroxide adopts the mass fraction of 30% hydrogen peroxide analytical pure reagent, and the mass percentage is 2%; Potassium hydroxide adopts analytical pure reagent, the mass percentage is 0.2%; the balance is pure water, and the resistance is 13 megohms.

[0057] 3) The batch of monocrystalline silicon wafers cleaned in step 2) are ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com