Ternary piezoelectric material with high curie temperature and preparation method

A Curie temperature, piezoelectric material technology, applied in the field of piezoelectric materials and preparation, can solve the problems of harsh process conditions, low piezoelectric performance, high cost, etc., to achieve no special equipment and harsh conditions, excellent performance, improved pressure. The effect of electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: According to the material composition A: 0.65BiFeO 3 -0.05LiNbO 3 -0.30PbTiO 3 +0.02molCeO 2 +0.02molSb 2 o 3 The molar stoichiometric ratio is used for batching, and the analytically pure raw material Bi is weighed 2 o 3 , Fe 2 o 3 , Li 2 CO 3 、TiO 2 , Nb 2 o 5 , CeO 2 and Sb 2 o3 , put it into a ball mill jar, the ball mill medium is absolute alcohol and zirconia balls, the weight ratio of material: ball: alcohol is 2:1:0.5, ball mill 6h, the rotating speed is 600 rpm, after drying the mixture, Put it into a corundum crucible for compaction, cover and seal it, and keep it warm in a muffle furnace at a temperature of 900°C for 2 hours. After coarse crushing and grinding, put the synthesized block into a ball mill jar, and grind it with zirconia balls and distilled water. Medium, material: the weight ratio of ball: water is 2:1:1, the ball mill is 12 hours, the speed is 600 rpm, after the powder is dried, add PVA (polyvinyl alcohol) with a weig...

Embodiment 2

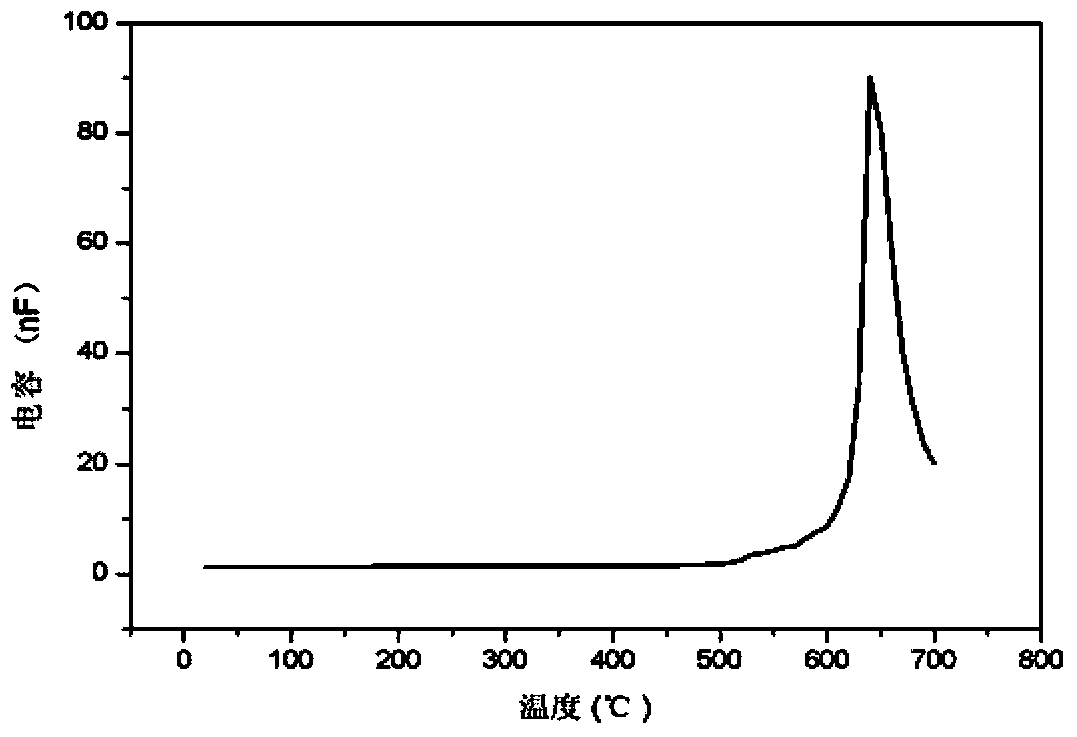

[0025] Example 2: According to the material composition B: 0.70BiFeO 3 -0.02LiNbO 3 -0.28PbTiO 3 +0.01molCeO 2 +0.01molSb 2 o 3 The molar stoichiometric ratio is used for batching, the pre-firing synthesis temperature is 800°C, and the temperature is kept for 6 hours. mm, the polarization time is 20 minutes, and all the other processes are the same as in Example 1; the performance of the element tested after placing it for 48 hours is: piezoelectric constant d 33 =122pC / N, electromechanical coupling coefficient kp=0.36, Qm=160, Curie temperature Tc=645℃;

Embodiment 3

[0026] Embodiment 3: Composition C by material:

[0027] 0.62BiFeO 3 -0.10LiNbO 3 -0.28PbTiO 3 +0.03molCeO 2 +0.05molSb 2 o 3 The stoichiometric ratio is used for batching, the pre-sintering synthesis temperature is 1000°C, heat preservation for 1h, sintering temperature is 1260°C, heat preservation for 3 hours, oil bath polarization is carried out in dimethyl silicone oil at 140°C, and the polarization voltage is 5000V / mm, Polarization time is 30 minutes, and all the other processes are identical with embodiment 1; The component performance tested after placing 48 hours is: piezoelectric constant d 33 =185pC / N, electromechanical coupling coefficient kp=0.45, Qm=60, Curie temperature Tc=605℃;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com