Process for preparing diisobutyl phthalate by electro-catalytic degradation of lignin in fixed bed reactor

A technology of diisobutyl phthalate and fixed bed reactor, which is applied in chemical industry, electrolysis process, electrolysis components, etc., can solve the problems of industrial production cost increase, long reaction cycle, expensive catalyst, etc., and achieve good results The effect of industrial application value, mild reaction conditions, and easy operation of process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) First prepare 0.5mol / L NaOH solution, take out 20mL and dilute it into a 1L volumetric flask to make a NaOH solution with pH=11.

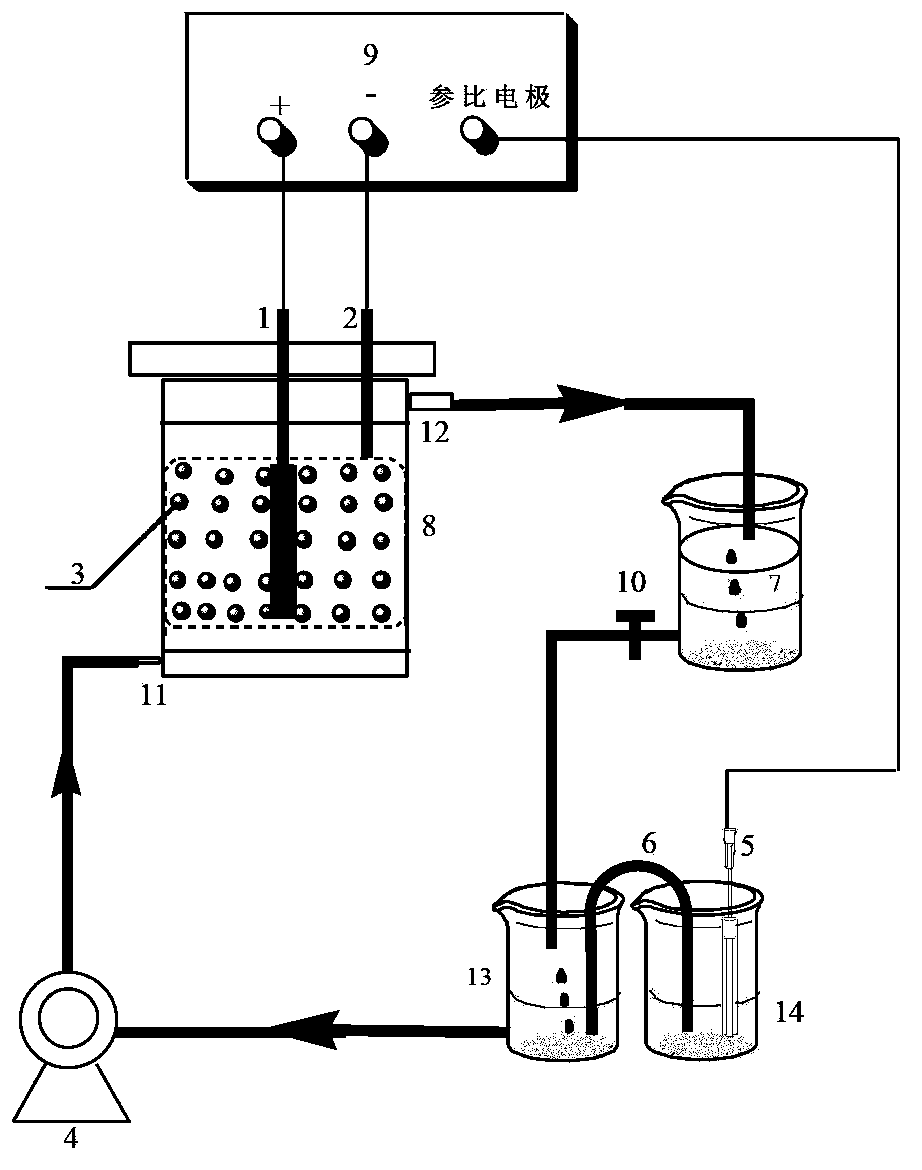

[0040] (2) Dissolve 11g of lignin in 1L of the NaOH solution prepared in step (1), the lignin concentration is 11g / L, pour it into the three-dimensional fixed bed reactor 8 as the electrolyte, and import the remaining lignin alkali solution into the storage tank 13 middle.

[0041] (3) Connect the working electrode 1, the auxiliary electrode 2 and the reference electrode 5 to the TD-3691A potentiostat 9 (Tianjin Zhonghuan Electronic Instrument Co., Ltd.) with wires.

[0042] (4) Turn on the circulating pump 4 to inject the lignin alkali solution in the storage tank 13 into the three-dimensional fixed-bed reactor 8 through the inlet 11, and the electrolyzed reaction solution flows into the extraction bottle 7 through the outlet 12 for extraction and layering , the lower liquid, that is, the extracted reaction solution, flows into the sto...

Embodiment 2~8

[0050] In Examples 2-8, under the conditions of reaction time of 4 hours, pH=13, and lignin concentration of 11g / L, the effects of different current densities on the product DIBP concentration (see Table 1), other operating steps are the same as in Example 1.

[0051] The impact of table 1 current density on the concentration of diisobutyl phthalate

[0052] project Current density (mA / cm 2 ) DIBP concentration (mg / L) Example 2 10 0.9 Example 3 15 4.8 Example 4 20 0.27 Example 5 25 5.7 Example 6 30 1.15 Example 7 35 1.2 Example 8 40 4.35

Embodiment 9~11

[0054] Embodiment 9~11 is 4h in reaction time, and current density 25mA / cm 2 , the effect of different pH values on the product DIBP concentration under the condition that the lignin concentration is 11g / L (see Table 2), and other operating steps are the same as in Example 1.

[0055] The impact of table 2pH value on the concentration of diisobutyl phthalate

[0056] project pH value DIBP concentration (mg / L) Example 9 11 5.55 Example 10 12 1.65 Example 11 13 5.7

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com