Organic sulfur hydrolysis catalyst applicable to natural gas large-scale sulfur recovery device and preparation method thereof

A technology of hydrolysis catalyst and sulfur recovery, which is applied in the direction of catalyst activation/preparation, sulfur preparation/purification, catalyst carrier, etc., and can solve the problem of high organic sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

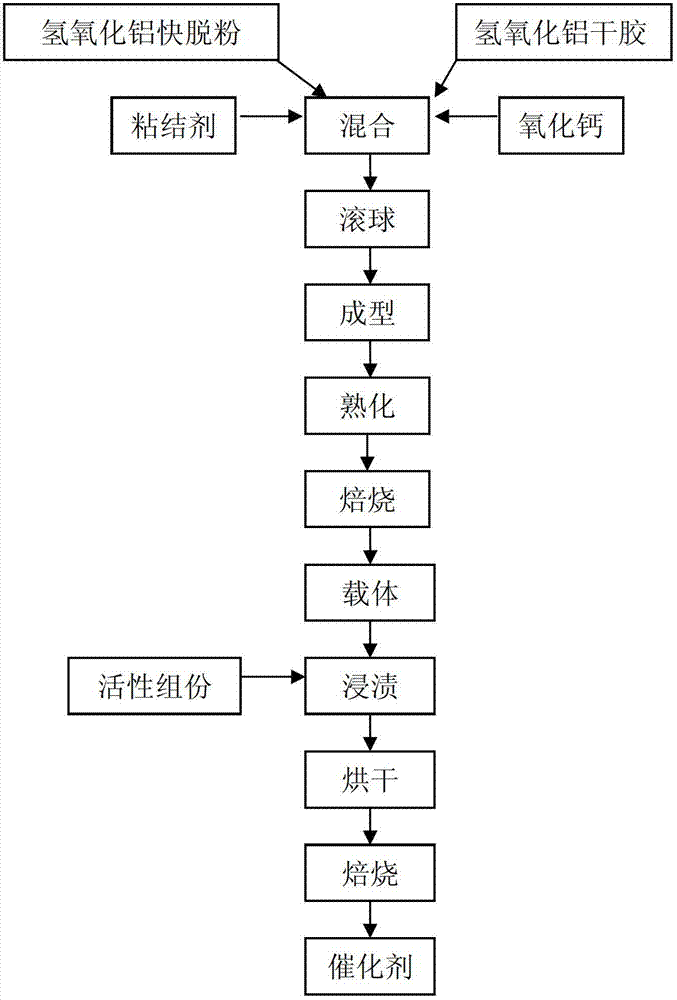

[0109] Weigh the specific surface as 422m 2 1 kg of aluminum hydroxide dry glue with a pore volume of 1.10 ml / g and a pore volume of 1.10 ml / g is placed in a roasting furnace, and dehydrated and dried for 2 hours at 550 ° C. Weigh 4 kg specific surface is 320m 2 Calcium oxide of 99% calcium oxide is the fast de-powder of aluminum hydroxide of 0.41ml / g of pore volume 0.41ml / g and 50 grams of purity, mixes evenly with the aluminum hydroxide dry glue after the dehydration.

[0110] Take by weighing 402 grams of acetic acid with a purity of 99.5%, dissolve it in water, stir evenly, and configure it as a binding agent. Put the uniformly mixed solid material in the rolling ball machine, slowly spray the prepared binder into the mixed solid material, rotate the rolling ball to form, and get Catalyst pellets are prepared by aging the pellets in a water vapor atmosphere at 100°C for 20 hours, drying at 120°C for 4 hours, and calcining at 400°C for 3 hours to prepare the catalyst carr...

Embodiment 2

[0112] Weigh the specific surface as 422m 2 1 kg of aluminum hydroxide dry glue with a pore volume of 1.10 ml / g and a pore volume of 1.10 ml / g is placed in a roasting furnace, and dehydrated and dried for 2 hours at 550 ° C. Weigh 5 kg specific surface is 320m 2 Calcium oxide of 99% calcium oxide is the quick de-powder of aluminum hydroxide of 0.41ml / g of pore volume 0.41ml / g and 60 grams of purity, mixes evenly with the aluminum hydroxide dry glue after the dehydration.

[0113] Take by weighing 402 grams of acetic acid with a purity of 99.5%, dissolve it in water, stir evenly, and configure it as a binding agent. Put the uniformly mixed solid material in the rolling ball machine, slowly spray the prepared binder into the mixed solid material, rotate the rolling ball to form, and get Catalyst pellets are prepared by aging the pellets in a water vapor atmosphere at 100°C for 20 hours, drying at 120°C for 4 hours, and calcining at 400°C for 3 hours to prepare the catalyst ca...

Embodiment 3

[0115] Weigh the specific surface as 422m 2 1 kg of aluminum hydroxide dry glue with a pore volume of 1.10 ml / g and a pore volume of 1.10 ml / g is placed in a roasting furnace, and dehydrated and dried for 2 hours at 550 ° C. Weigh 4 kg specific surface is 320m 2 Calcium oxide of 99% calcium oxide is the fast de-powder of aluminum hydroxide of 0.41ml / g of pore volume 0.41ml / g and 50 grams of purity, mixes evenly with the aluminum hydroxide dry glue after the dehydration.

[0116] Take by weighing 402 grams of acetic acid with a purity of 99.5%, dissolve it in water, stir evenly, and configure it as a binding agent. Put the uniformly mixed solid material in the rolling ball machine, slowly spray the prepared binder into the mixed solid material, rotate the rolling ball to form, and get Catalyst pellets are prepared by aging the pellets in a water vapor atmosphere at 100°C for 20 hours, drying at 120°C for 4 hours, and calcining at 400°C for 3 hours to prepare the catalyst car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com