Steel plate descaling device based on slurry ejection and ultrasonic guided wave composite

An ultrasonic guided wave and descaling device technology, which is applied to used abrasive treatment devices, abrasive jet machine tools, abrasives, etc., can solve problems such as workpiece deformation, environmental pollution, and dirty steel surface, saving materials and energy. , Improve descaling efficiency and reduce power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

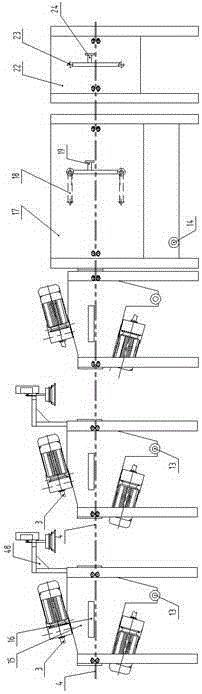

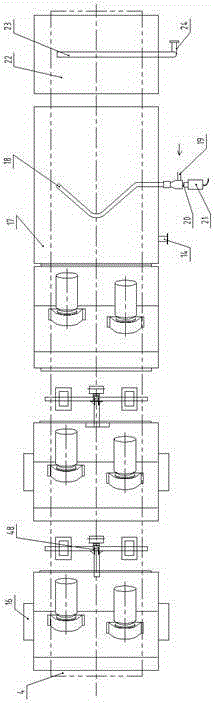

[0037] Such as figure 1 , figure 2As shown, the device of the present invention includes three descaling mechanisms with the same structure, two image detection mechanisms with the same structure, a steel plate scouring mechanism, an air-drying mechanism and a descaling slurry recycling mechanism; three descaling mechanisms, a steel plate scouring mechanism, The air-drying mechanisms are arranged and connected in sequence. An image detection mechanism is installed between two adjacent descaling mechanisms. Each descaling mechanism is connected with industrial computer 52 respectively.

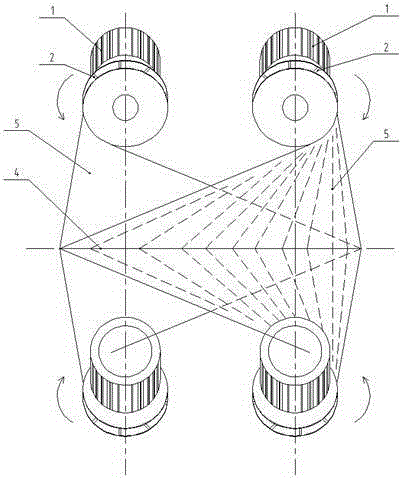

[0038] Such as Figure 3 ~ Figure 6 As shown, the descaling mechanism includes a descaling chamber 7, a descaling frame 12, two electromagnetic ultrasonic guided wave exciters 16 and four slurry ejectors with the same structure; the descaling chamber 7 is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com