Window film with automatically adjustable light transmittance

A technology of automatic adjustment and light transmittance, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve the problems of high reflection, low definition, high cost, etc., and achieve simple manufacturing process and increase the appearance Effect, the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

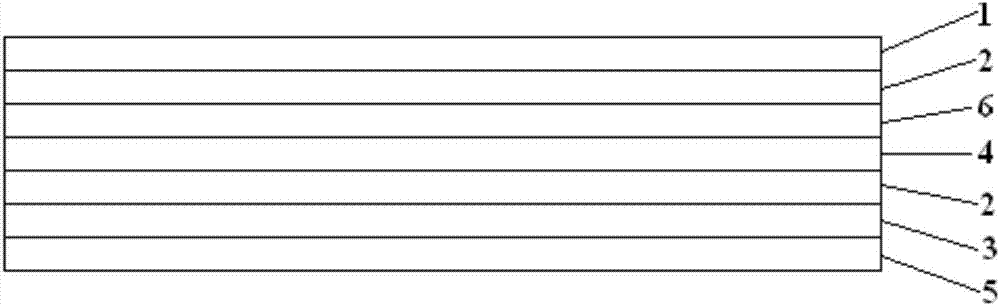

Embodiment 1

[0038] 1) Add ash 208, 2-(2'-hydroxy-6-tert-butyl-5'-methylphenyl)-5-chlorinated benzotriazole, Add the pressure-sensitive adhesive and ethyl acetate into the mixer, stir continuously to raise the temperature to 50°C, then keep the temperature constant, continue to stir for 0.5 hours, and cool down to obtain a photochromic pressure-sensitive adhesive;

[0039] 2) The photochromic pressure-sensitive dye glue is uniformly coated on the PET base film with a thickness of 23 μm by slit coating to form a photochromic pressure-sensitive adhesive layer 6 with a thickness of 12 μm. After drying, the glue-coated PET base film 2 is compounded with the PET base film 2 coated with a 30nm thick aluminum heat insulation layer 4 to obtain a composite film.

[0040] 3) One side of the composite film is coated with a scratch-resistant coating 1 with a thickness of 2 μm by dimple coating, and after being cured by ultraviolet light, a pressure-sensitive adhesive 3 with a thickness of 6 μm is coat...

Embodiment 2

[0043] 1) Add ash 306, 2-(2'-hydroxy-6-tert-butyl-5'-methylphenyl)-5-chlorinated benzotriazole with a mass ratio of 0.03:0.2:20:79.77 Add the pressure-sensitive adhesive and ethyl acetate into the mixer, stir continuously to raise the temperature to 50°C, then keep the temperature constant, continue to stir for 0.5 hours, and cool down to obtain a photochromic pressure-sensitive adhesive;

[0044] 2) The photochromic pressure-sensitive adhesive is evenly coated on the PET base film with a thickness of 23 μm by slit coating to form a photochromic pressure-sensitive adhesive layer 6 with a thickness of 8 μm. After drying, the glue-coated PET base film 2 is compounded with the PET base film 2 coated with a 20nm thick aluminum heat-insulating layer 4 to obtain a composite film.

[0045] 3) One side of the composite film is coated with a scratch-resistant coating 1 with a thickness of 3 μm by dimple coating, and after being cured by ultraviolet light, the other side is coated with ...

Embodiment 3

[0048] 1) Add ash 306, 2-(2'-hydroxy-6-tert-butyl-5'-methylphenyl)-5-chlorinated benzotriazole, Add the pressure-sensitive adhesive and ethyl acetate into the mixer, stir continuously to raise the temperature to 50°C, then keep the temperature constant, continue to stir for 0.5 hours, and cool down to obtain a photochromic pressure-sensitive adhesive;

[0049] 2) The photochromic pressure-sensitive adhesive is evenly coated on the PET base film with a thickness of 23 μm by slit coating to form a photochromic pressure-sensitive adhesive layer 6 with a thickness of 8 μm. After drying, the glue-coated PET base film 2 is combined with the PET base film 2 coated with a 20nm thick titanium heat insulation layer 4 to obtain a composite film.

[0050] 3) One side of the composite film is coated with a scratch-resistant coating 1 with a thickness of 4 μm by dimple coating. After being cured by ultraviolet light, a pressure-sensitive adhesive 3 with a thickness of 12 μm is coated on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com