Electrocatalytic wastewater treatment system

A wastewater treatment system, electrocatalysis technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of increasing system energy consumption and device volume, and reduce wastewater treatment Cost, improvement of reaction efficiency, and time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

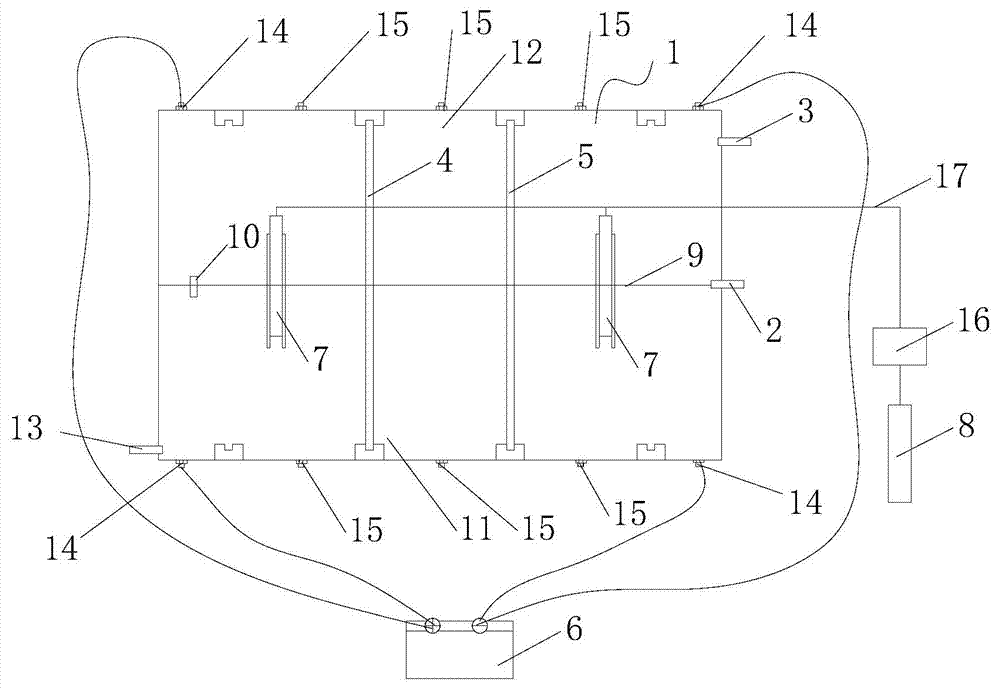

Method used

Image

Examples

Embodiment 1

[0058] Analysis of the treatment effect of the effluent after biochemical treatment of oil refinery wastewater.

[0059] Refining wastewater is refractory wastewater. The refining process consumes a lot of water, and the water quality of the discharged wastewater is complex and highly volatile. Using the above-mentioned wastewater treatment system with a treatment capacity of 60L / h, a 30-day on-site continuous operation test was carried out on the wastewater discharged from an oil refinery after biochemical treatment. The results show that: when the influent water quality index COD fluctuates between 80.0-360mg / L, the average value is 220mg / L; when the ammonia nitrogen concentration is around 40.0mg / L, the control reaction time is 20min, and the COD of the system effluent after the reaction is lower than 50mg / L, the average removal rate can reach 80.1%; the concentration of ammonia nitrogen in the effluent is lower than 4mg / L, and the removal rate of ammonia nitrogen can reach...

Embodiment 2

[0061] Analysis of the treatment effect of printing and dyeing wastewater after biochemical treatment.

[0062] The printing and dyeing industry consumes a lot of water, the water quality is complicated, and the concentration of pollutants fluctuates greatly. Using the above-mentioned wastewater treatment system with a treatment capacity of 60L / h, a 3-week on-site continuous operation test was carried out on the biochemical discharge water of a number of printing and dyeing wastewater. The main water quality indicators of the experimental water are: the COD fluctuation of the influent water quality index is between 80-120mg / L, and the average value is 100mg / L; the chroma is 40-80, and the average value is 60. The reaction time was controlled at 20 min during the experiment. The results of water discharge show that when the dielectric barrier plasma generator 16 is not working, the average COD removal rate of the system can still reach 70%, and the chroma removal rate is close...

Embodiment 3

[0064] Analysis of the effect of advanced treatment on effluent after biochemical treatment of petrochemical wastewater.

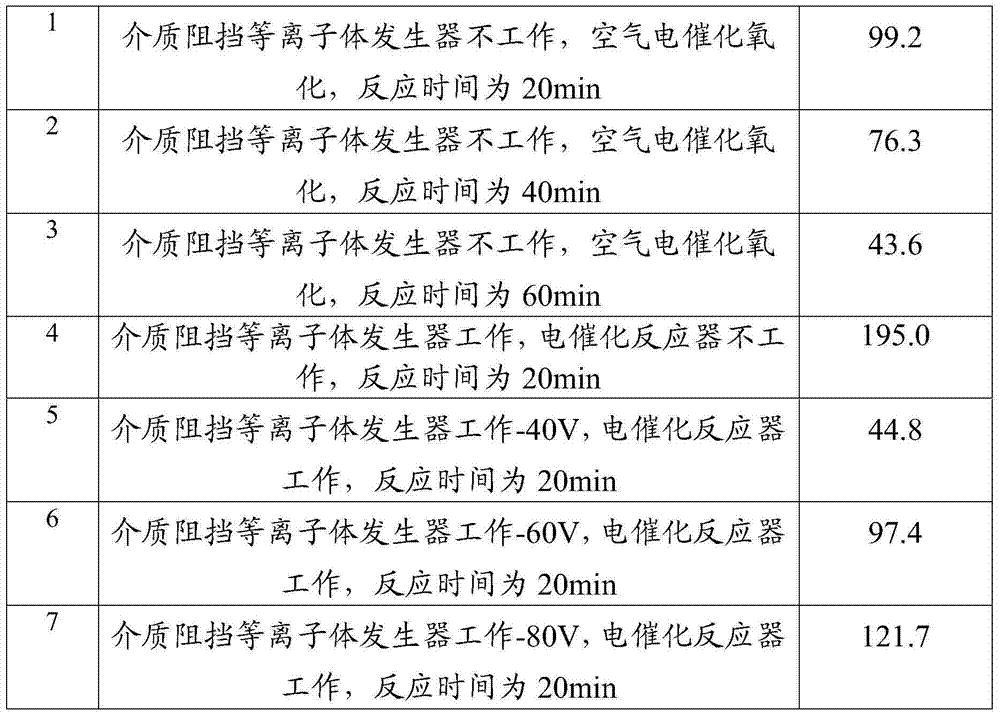

[0065]Petrochemical or coking wastewater has the remarkable characteristics of oxidation and refractory degradation. It is difficult to effectively degrade it by traditional advanced oxidation methods such as ozone, electrolysis, and Fenton method. Using a laboratory small-scale electrocatalysis experimental device (note: the effective volume of the experimental device is 400mL, there are 3 pairs of 316L stainless steel working electrodes 14, the distance between each pair of working electrodes 14 is 2cm, and the length of the reaction tank is 10cm) to measure the presence or absence of plasma The comparative results of the flow-time electrocatalytic wastewater treatment system on petrochemical wastewater under different conditions are shown in Table 1. The test water quality is: the COD fluctuation of the influent varies between 180-220mg / L, and the aver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com