Method for extracting p-tertbutyl benzaldehyde from oxidation reactant of p-tertbutyl methylbenzene through integration of liquid-liquid extraction crystallization and decompression sidetrack rectification

A technology of p-tert-butyltoluene and tert-butyl benzoic acid, applied in the field of p-tert-butyl benzaldehyde, can solve the problems of inconvenient control of product quality, large equipment investment, long technological process, etc., and achieve convenient product quality and equipment investment. Reduced, no impact on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

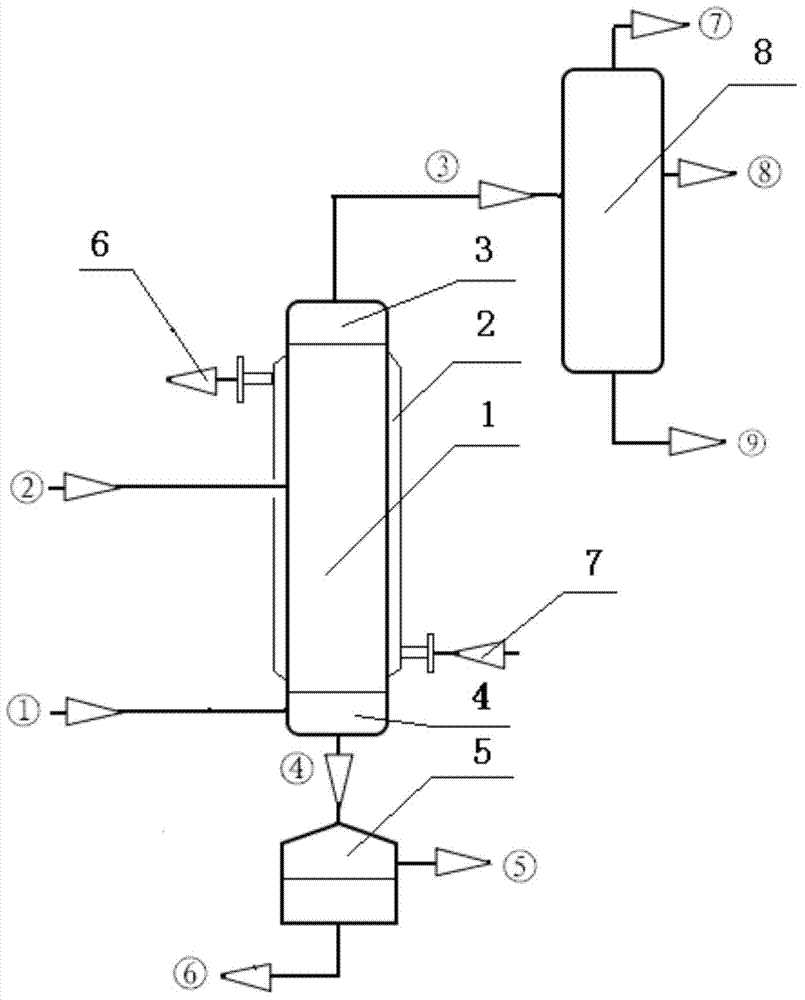

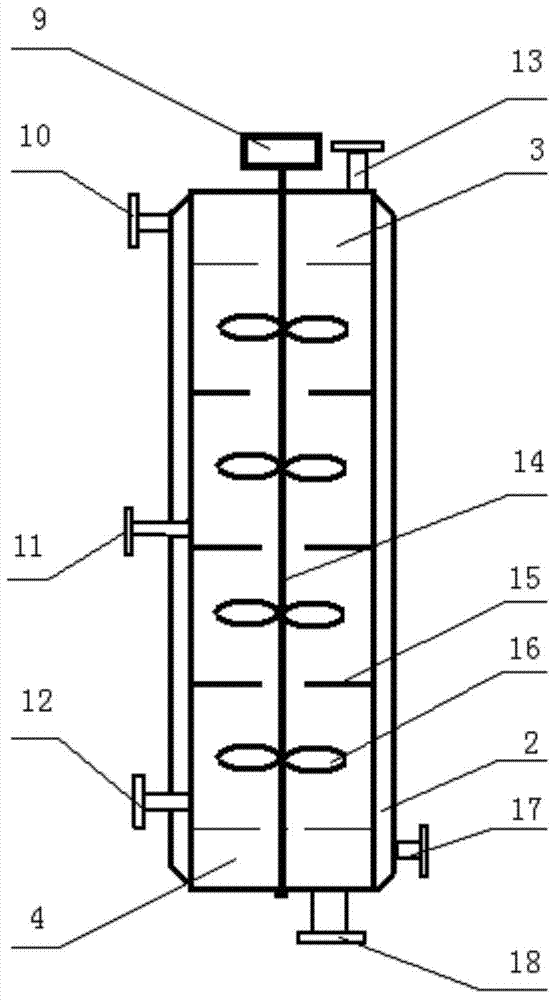

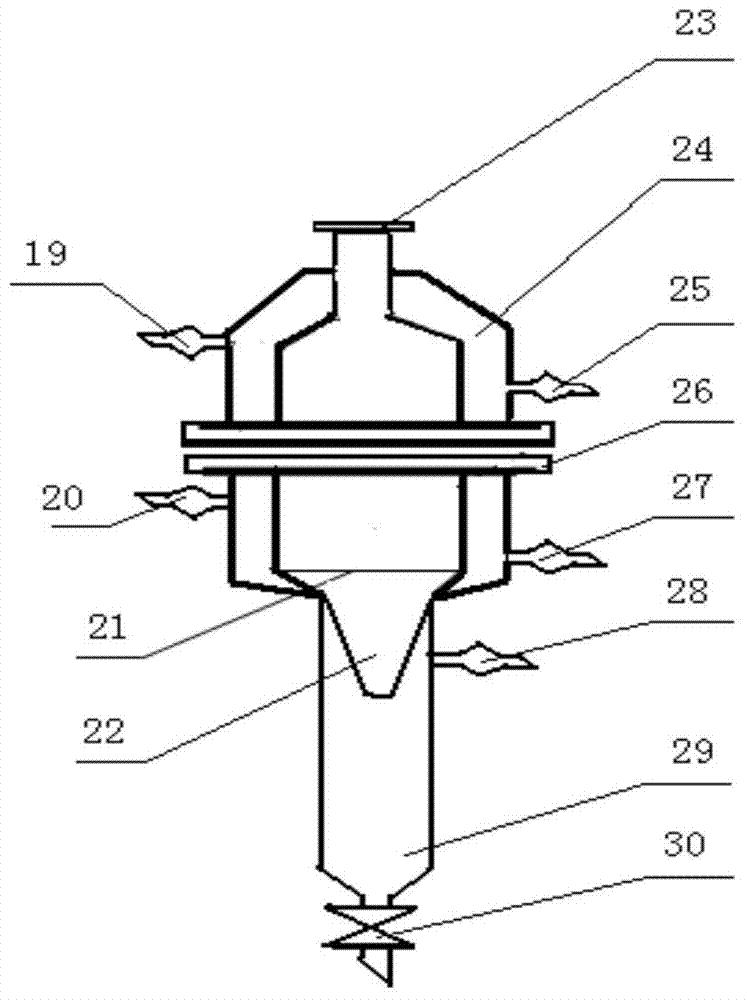

[0028] Embodiment 1, liquid-liquid extraction crystallization and vacuum side stream rectification integrated separation method for p-tert-butyltoluene, p-tert-butylbenzaldehyde and p-tert-butylbenzoic acid, refer to figure 1 The process diagram shown and figure 2 and image 3 The device shown, the specific flow of the integrated process of extraction crystallization and vacuum side stream rectification is: at room temperature, raw materials ② For p-tert-butyltoluene, p-tert-butylbenzaldehyde and p-tert-butylbenzoic acid mixed solution at first enter extraction crystallization tower 1, extractant ① Benzene enters the extraction and crystallization tower 1 below the raw materials, and is fully stirred with the raw materials. The temperature of the extraction and crystallization tower is controlled at 28.3°C, and the layers are separated and crystallized. See Table 2 for the content of each component of the remaining phase ④. The extraction phase enters the vacuum distillati...

Embodiment 2

[0030] Embodiment 2 is basically the same as Example 1, but the raw materials in step (1) consist of: 37.1% p-tert-butyltoluene, 52.23% p-tert-butylbenzaldehyde and 10.67% p-tert-butylbenzoic acid. In step (2), the mass ratio of raw material / extractant toluene is 1:0.7-1.0; the actual number of stages in the extraction and crystallization section is 4 stages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com