Fully-biodegradable composite membrane filled with nano silver/cellulose nanocrystal composite particles, and preparation method thereof

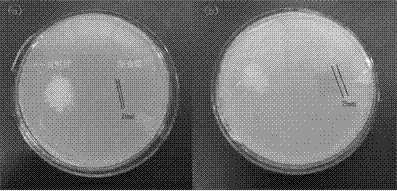

A nanocrystalline composite and biodegradable technology, which is applied in the field of new multifunctional fully biodegradable composite films and its preparation, can solve the problem that the antibacterial effect of Staphylococcus aureus is not obvious, achieve improved mechanical and thermal properties, and wide application Foreground, performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

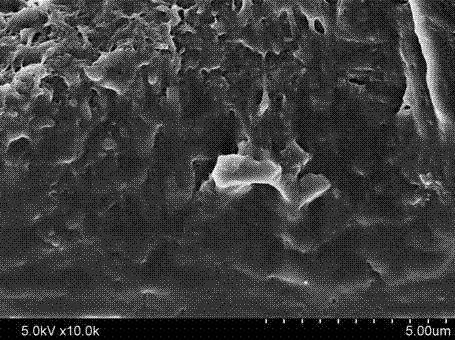

[0021] Add microcrystalline cellulose to formic acid / hydrochloric acid solution, wherein the solid-to-liquid ratio of microcrystalline cellulose and mixed acid aqueous solution is 1:60 g / mL, and formic acid (9 mol / L) and hydrochloric acid (5 mol / L) in mixed acid aqueous solution The volume ratio of the mixture is 6:1, and the mixed solution is reacted at 48 ℃ for 12 h. After the reaction is completed, the reaction product is washed with deionized water until it is neutral to obtain aldylated cellulose nanocrystals; In the silver nitrate solution of L, the solid-to-liquid ratio of cellulose nanocrystals and silver nitrate solution was 1:200 g / mL, and the mixed solution was reacted at 92 °C for 20 min. After natural cooling, it was diluted with deionized water. The reaction product is centrifuged several times to remove inorganic ions, and then the dispersion is vacuum-dried to obtain nano-silver / cellulose nano-crystal composite particles;

[0022] Slowly add nano-silver / cellulo...

Embodiment 2

[0026] Add wood pulp into formic acid / hydrochloric acid solution, wherein the solid-to-liquid ratio of wood pulp and mixed acid aqueous solution is 1:80 g / mL, and the volume ratio of formic acid (8 mol / L) to hydrochloric acid (6 mol / L) in mixed acid aqueous solution is 6:1, the mixed solution was reacted at 42 °C for 15 h. After the reaction was completed, the reaction product was washed with deionized water until neutral to obtain aldylated cellulose nanocrystals; then added 0.5 mol / L silver nitrate In the solution, the solid-to-liquid ratio of the aldylated cellulose nanocrystals to the silver nitrate solution was 1:100 g / mL, and the mixed solution was reacted at 60 °C for 30 min. After natural cooling, the reaction product was diluted with deionized water. Centrifuge once to remove inorganic ions, and then vacuum-dry the dispersion to obtain nano-silver / cellulose nanocrystalline composite particles;

[0027] Slowly add nano-silver / cellulose nanocrystalline composite particl...

Embodiment 3

[0031] Bamboo fiber was added to formic acid / hydrochloric acid solution, the solid-to-liquid ratio of bamboo fiber to the mixed acid aqueous solution was 1:20 g / mL, and the volume ratio of formic acid (3 mol / L) to hydrochloric acid (8 mol / L) in the mixed acid aqueous solution was 6:1, the mixture was reacted at 40 °C for 5 h, and after the reaction was completed, the reaction product was washed with deionized water until it was neutral, and the aldylated cellulose nanocrystals could be obtained; then 2 mol / L silver nitrate was added to it In the solution, the solid-to-liquid ratio of the aldylated cellulose nanocrystals to the silver nitrate solution was 1:400 g / mL, and the mixed solution was reacted at 80 °C for 45 min. After natural cooling, the reaction product was diluted with deionized water. Centrifuge once to remove inorganic ions, and then vacuum-dry the dispersion to obtain nano-silver / cellulose nanocrystalline composite particles;

[0032] Slowly add nano-silver / cell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com