Production method for butyric acid through anaerobic fermentation of excess sludge

An anaerobic fermentation and excess sludge technology, applied in the field of solid organic waste recycling, can solve the problems of unsatisfactory economic benefits of excess sludge and low added value of products, so as to alleviate the pressure of environmental pollution and promote metabolism and growth , the effect of enhancing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described below in conjunction with the accompanying drawings and examples, but not limited by the accompanying drawings and examples.

[0015] The method of the present invention is described as follows:

[0016] The invention relates to a method for increasing the yield of butyric acid produced from organic matter in excess sludge by using excess sludge as raw material and adding a composition of trace hydrated metal compounds that enhance the activity of butyrate-producing bacteria. Specifically include the following steps:

[0017] (1) Using excess sludge as raw material, adjust the solid mass concentration of sludge, add NaOH to process and centrifuge, and get the supernatant as the substrate for anaerobic fermentation to produce butyric acid;

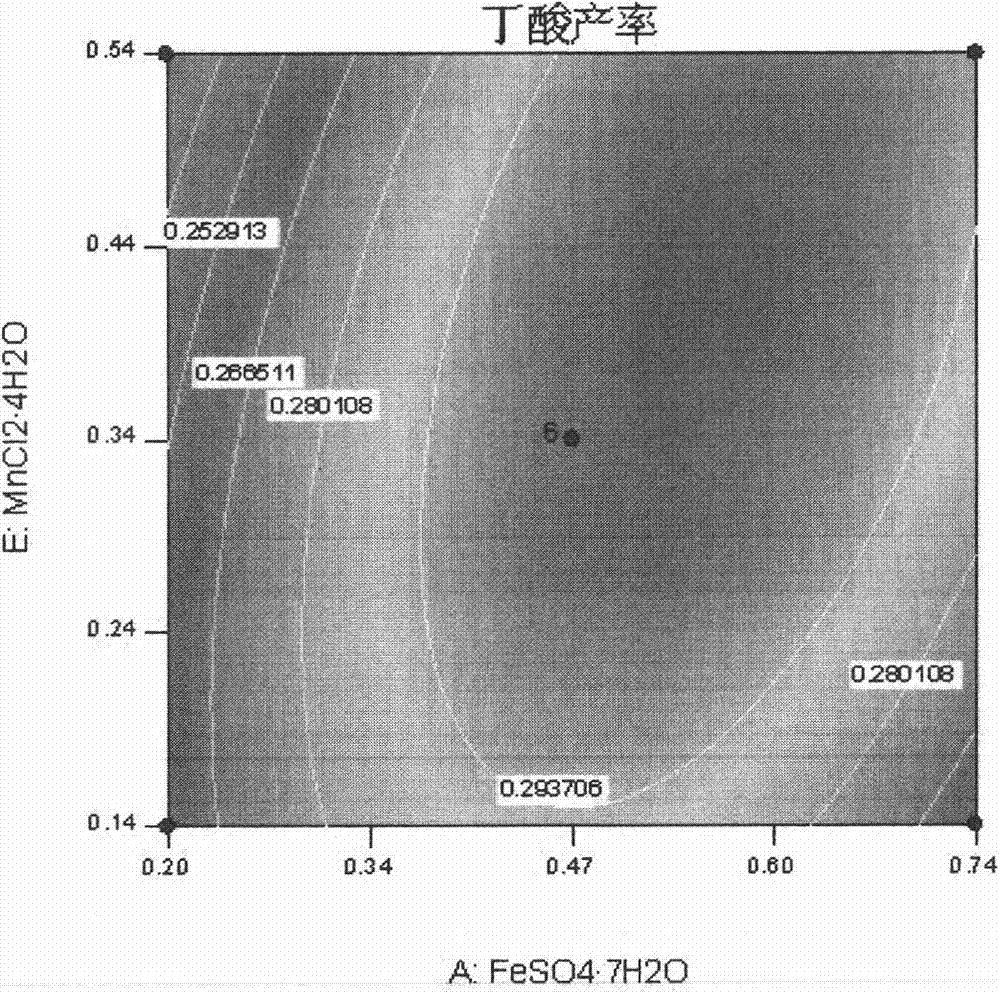

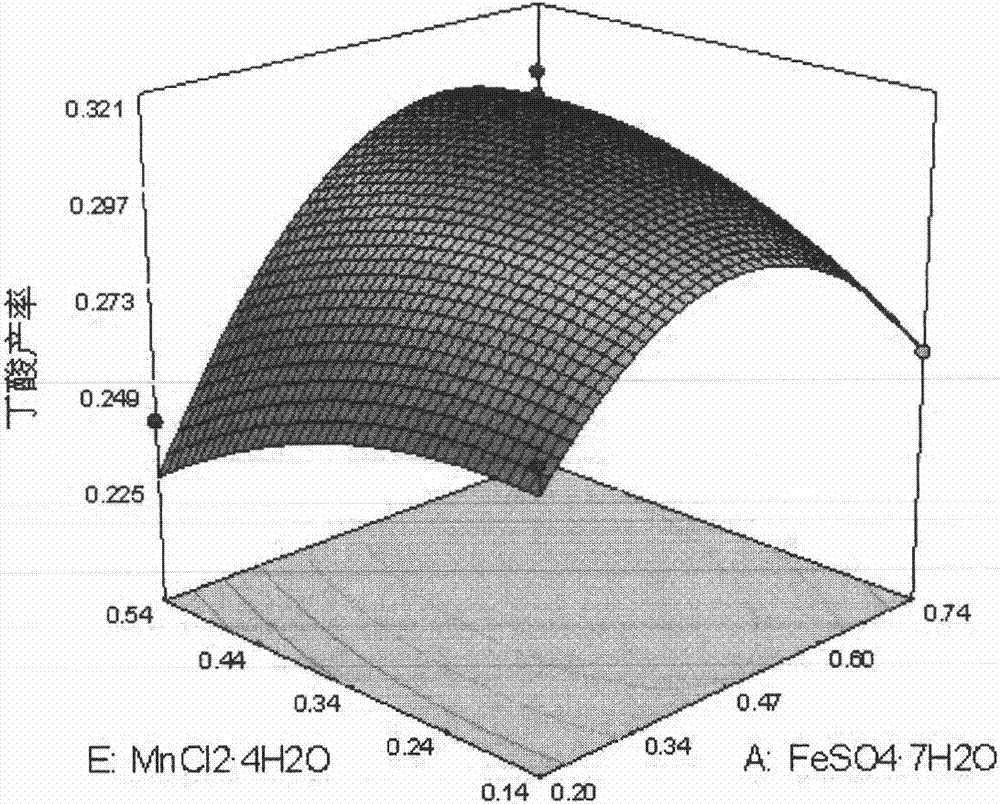

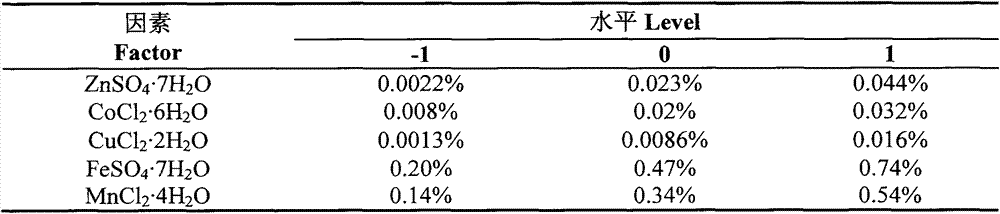

[0018] (2) Choose ZnSO 4 ·7H 2 O, CoCl 2 ·6H 2 O, CuCl 2 2H 2 O, MnCl 2 4H 2 O and FeSO 4 ·7H 2 The five factors are independent variables, and different levels are designed respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com