Thermal treatment method for hydrogen removing of titanium wires

A heat treatment method and technology for titanium wire, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of wire elongation and strength loss, high annealing temperature, long annealing time, etc., and achieve simple treatment methods and clever design. , Remarkable effect of removing hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] TA1 pure titanium wire (its starting recrystallization temperature T rs 590°C, the final recrystallization temperature T re 650°C) dehydrogenation heat treatment:

[0019] Put the TA1 pure titanium wire after pickling treatment into the vacuum heat treatment furnace, and the vacuum degree is not more than 1.0×10 -2 Under the vacuum condition of Pa, the TA1 pure titanium wire was heated up to 560°C at a heating rate of 6°C / min and then kept for 80 minutes, then raised to 600°C at a heating rate of 6°C / min and kept for 100 minutes, and finally heated at 6°C / min The heating rate was increased to 660°C and then kept for 80 minutes.

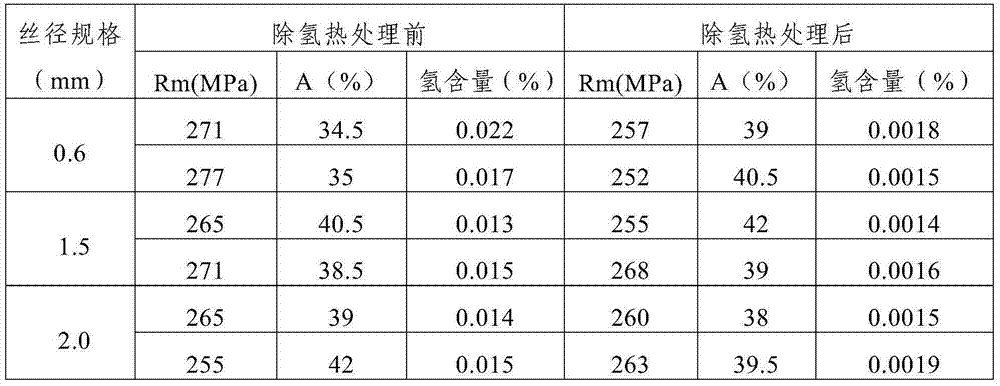

[0020] The TA1 pure titanium wire after hydrogen removal heat treatment was cooled naturally or with argon to room temperature of 25°C, and then the mechanical properties and hydrogen content were tested. The test data are shown in Table 1.

[0021] Table 1 Example 1 Mechanical properties and hydrogen content of TA1 pure titanium wire before...

Embodiment 2

[0025] TA1ELI pure titanium wire (its starting recrystallization temperature T rs 570°C, the final recrystallization temperature T re 640°C) dehydrogenation heat treatment:

[0026] Put the TA1ELI pure titanium wire after pickling treatment into the vacuum heat treatment furnace, and the vacuum degree is not more than 1.0×10 -2 Under the vacuum condition of Pa, the TA1ELI pure titanium wire was heated up to 550°C at a heating rate of 6°C / min and then kept for 80 minutes, then raised to 580°C at a heating rate of 6°C / min and kept for 100 minutes, and finally heated at 6°C / min The heating rate was increased to 660°C and then kept for 80 minutes.

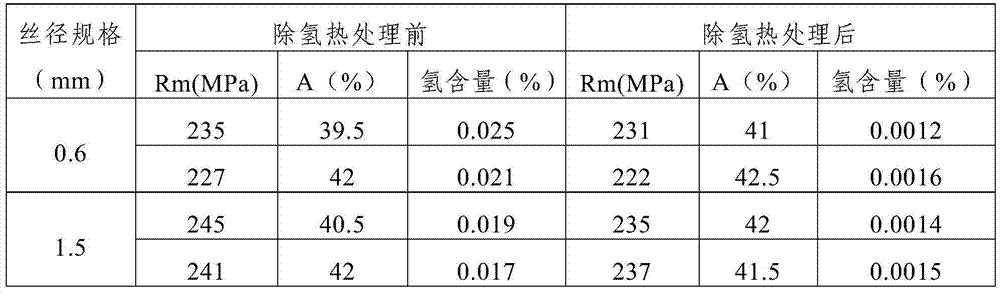

[0027] The TA1ELI pure titanium wire after hydrogen removal heat treatment was cooled naturally or with argon to a room temperature of 25°C, and then the mechanical properties and hydrogen content were tested. The test data are shown in Table 2.

[0028] Table 2 Example 2 Mechanical properties and hydrogen content of TA1ELI pure tit...

Embodiment 3

[0032] TA2 pure titanium wire (its recrystallization temperature T rs 650°C, the final recrystallization temperature T re 750°C) dehydrogenation heat treatment:

[0033] Put the TA2 pure titanium wire after pickling treatment into the vacuum heat treatment furnace, and the vacuum degree is not more than 1.0×10 -2 Under the vacuum condition of Pa, the TA2 pure titanium wire was heated up to 620°C at a heating rate of 8°C / min and then kept for 40 minutes, then raised to 680°C at a heating rate of 8°C / min and kept for 100 minutes, and finally heated at 8°C / min The heating rate was increased to 750°C and then kept for 80 minutes.

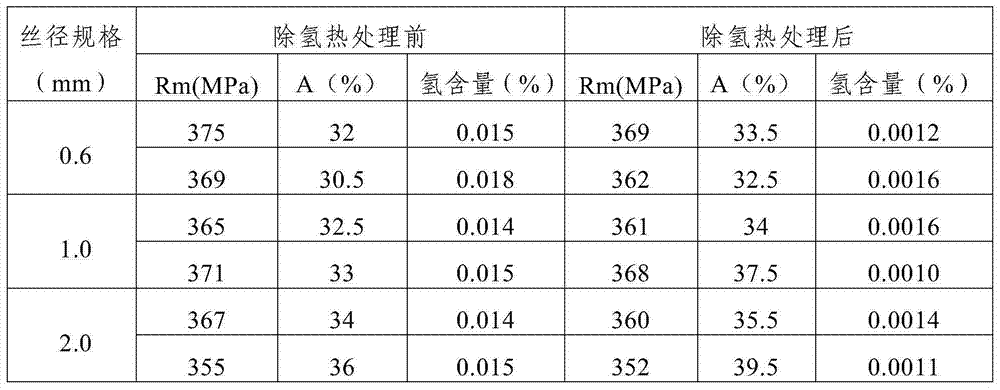

[0034] The TA2 pure titanium wire after hydrogen removal heat treatment was cooled naturally or with argon to a room temperature of 25°C, and then the mechanical properties and hydrogen content were tested. The test data are shown in Table 3.

[0035] Table 3 Example 3 Mechanical properties and hydrogen content of TA2 pure titanium wire before and af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com