Nitrogen polar surface light emitting diode with tunnel junction structure

A technology of tunnel junction and nitrogen polarity, used in electrical components, circuits, semiconductor devices, etc., can solve problems that are not very obvious in practice, and achieve the effect of improving ohmic contact and current expansion capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

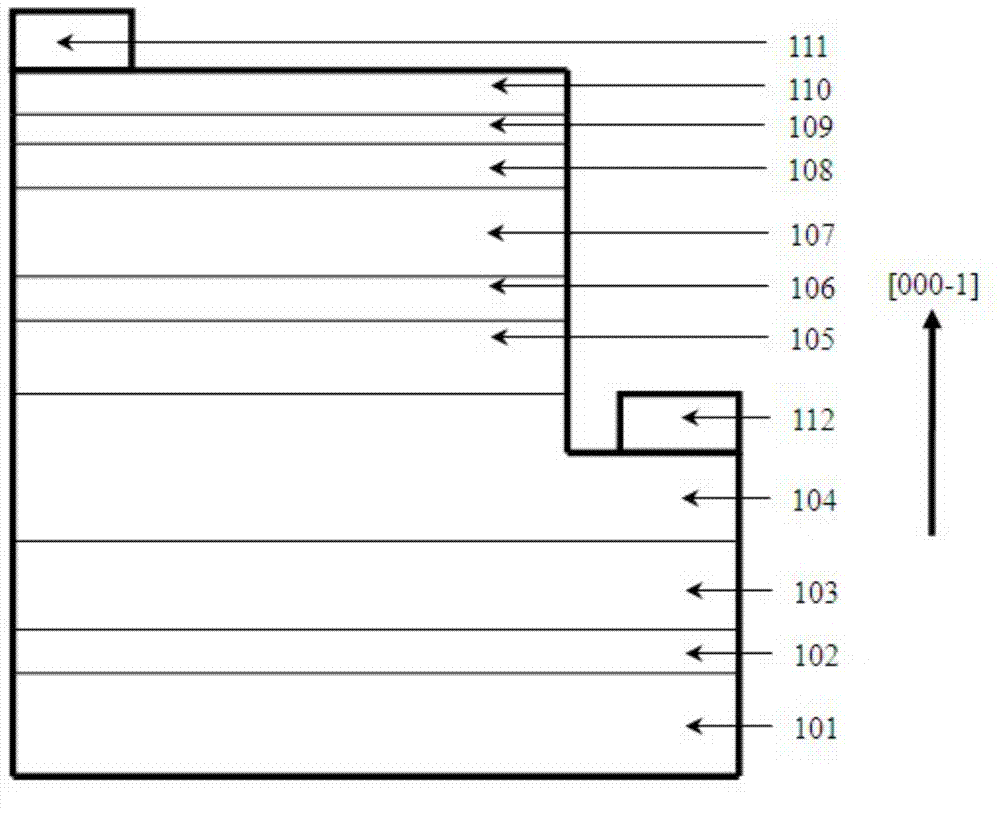

[0023] Such as figure 1 Shown is a nitrogen polar surface LED chip grown along the [000-1] direction, with a p-i-n tunnel junction structure as the top ohmic contact layer, including a sapphire substrate 101 and a low-temperature nucleation layer 102 arranged in sequence from bottom to top , non-doped semiconductor layer 103, n-type semiconductor layer 104, multi-quantum well active layer 105, p-AlGaN electron blocking layer 106, p-type semiconductor layer 107, p + -GaN layer 108, undoped In x Al y Ga 1-x-y N layer 109 , n-type superlattice structure layer 110 and metal electrode 111 .

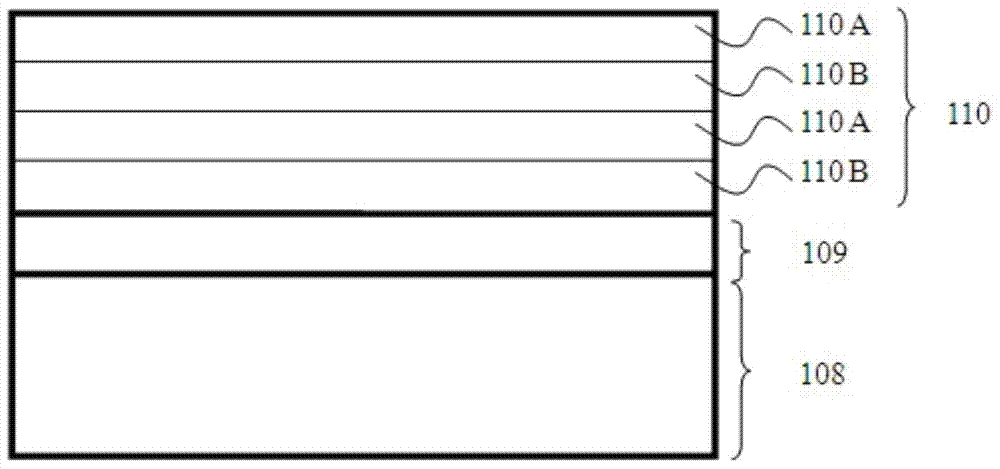

[0024] the p + -GaN layer 108, undoped In x Al y Ga 1-x-y The N layer 109 and the n-type superlattice structure layer 110 together form a p-i-n tunnel junction structure. Such as figure 2 Shown is the p-i-n tunnel junction structure of this example, and the n-type superlatti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com