Lithium-ion battery and its lithium-rich anode sheet

A lithium-ion battery and anode sheet technology, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of reduced energy density of batteries, complex production processes, and poor infiltration, so as to reduce production processes and Production equipment, improvement of first-time Coulombic efficiency, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

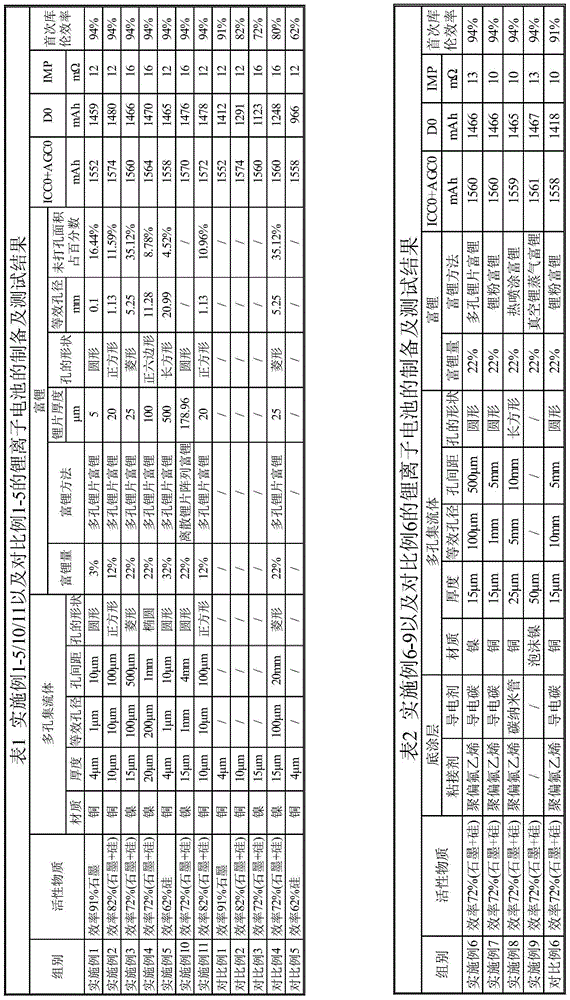

Examples

preparation example Construction

[0035] According to the preparation method of the lithium-rich anode sheet of the lithium-ion battery of the present invention, it is used to prepare the lithium-rich anode sheet of the lithium-ion battery described in the first aspect of the present invention, comprising the steps of: preparing a porous current collector, and then adding the active material, Conductive agent, binder and solvent are stirred to prepare slurry, and the slurry is coated on the porous current collector and dried to obtain the initial anode sheet, wherein the slurry coated on the current collector becomes a membrane after drying Carry out single-sided lithium-enrichment to the above-mentioned dried diaphragm to obtain a lithium-rich anode sheet for a lithium-ion battery, and the capacity of the single-sided lithium-enriched sheet matches the capacity of the original anode sheet that needs to be supplemented with lithium.

[0036] The lithium ion battery according to the third aspect of the present i...

Embodiment 1

[0040] A porous current collector

[0041] A copper perforated current collector with a thickness of 4 μm is selected, the shape of the hole is circular, the diameter of the hole (that is, the equivalent pore diameter) is 1 μm, and the hole spacing is 10 μm.

[0042] B preparation of initial anode sheet

[0043] The active material graphite (the gram capacity of graphite is 340mAh / g, the first coulombic efficiency is 91%), the binder (styrene-butadiene rubber), and the conductive agent (super conductive carbon) are mixed according to the ratio of mass ratio = 92:3:5 The solvent (nitromethylpyrrolidone) is mixed evenly to make a slurry, and then 100mg / 1540mm 2 The coating weight of the slurry is coated on the front and back of the above porous current collector; then dried to form a diaphragm and the water content of the diaphragm does not exceed 300ppm; after cold pressing, stripping, and welding the corresponding tabs An initial anode sheet with a width of 160 mm was produc...

Embodiment 2

[0060] With embodiment 1, except following difference with embodiment 1:

[0061] A porous current collector

[0062] A copper perforated current collector with a thickness of 10 μm is selected, the shape of the hole is square (side length is 8.86 μm), the equivalent pore diameter of the hole is 10 μm, and the hole spacing is 100 μm for use.

[0063] B preparation of initial anode sheet

[0064] A mixture of graphite and silicon (wherein the gram capacity of the mixture is 400mAh / g, and the first Coulombic efficiency is 82%) is the active material;

[0065] One side coating amount of slurry is 80mg / 1540mm 2 ;

[0066] The width of the prepared primary anode sheet was 100 mm.

[0067] C preparation of lithium-rich anode sheet (porous lithium sheet lithium-rich)

[0068] 1) Lithium-rich amount of lithium-rich anode sheet

[0069] The lithium-rich amount of the lithium-rich anode sheet is 12% of the capacity of the initial anode sheet;

[0070] The lithium-rich capacity re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com