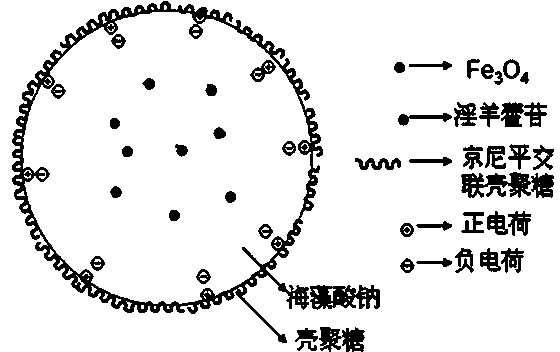

Autofluorescence bone repairing magnetic sustained-release microspheres

A slow-release microsphere and autofluorescence technology, which is applied in the field of bone filling material manufacturing, can solve the problems of high cytotoxicity of cross-linking agents and affect normal tissue growth, etc., and achieves superior biocompatibility, no toxic side effects, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Add 1.35g FeCl 3 ·6H 2O, 40ml ethylene glycol, 3.6g sodium acetate, magnetically stirred evenly, placed in a reaction kettle, after 12 hours of reaction, the obtained product was washed several times with absolute ethanol, several times with deionized water, centrifuged, 40°C vacuum drying;

[0044] (2) Sodium alginate was dissolved in deionized water with a mass percentage of 1.2%, and magnetically stirred for 1 hour;

[0045] (3) Add the prepared nano-magnetic Fe to the above solution 3 o 4 Powder, the mass percentage is 0.008%, electric stirring for 1h;

[0046] (4) Add an ethanol solution of icariin, with a mass percentage of 0.02%, and magnetically stir for 1 hour;

[0047] (5) Using a microcapsule forming device with a voltage of 1.3kv, use a syringe to drop the mixture in step (4) into the gel bath to form primary microspheres;

[0048] (6) Submerge the primary microspheres in a chitosan acetic acid solution with a mass percentage of 0.6% for 8 hours, a...

Embodiment 2

[0051] (1) Add 1.35g FeCl 3 ·6H 2 O, 40ml ethylene glycol, 3.6g sodium acetate, magnetically stirred evenly, placed in a reaction kettle, after 12 hours of reaction, the obtained product was washed several times with absolute ethanol, several times with deionized water, centrifuged, 40°C vacuum drying;

[0052] (2) Sodium alginate was dissolved in deionized water with a mass percentage of 1.4%, and magnetically stirred for 1 hour;

[0053] (3) Add the prepared nano-magnetic Fe to the above solution 3 o 4 Powder, the mass percentage is 0.008%, electric stirring for 1h;

[0054] (4) Add an ethanol solution of icariin, with a mass percentage of 0.03%, and magnetically stir for 1 hour;

[0055] (5) Using a microcapsule forming device with a voltage of 1.3kv, use a syringe to drop the mixture in step (4) into the gel bath to form primary microspheres;

[0056] (6) Submerge the primary microspheres in a chitosan acetic acid solution with a mass percentage of 0.8% for 10 hours,...

Embodiment 3

[0059] (1) Add 1.35g FeCl 3 ·6H 2 O, 40ml ethylene glycol, 3.6g sodium acetate, magnetically stirred evenly, placed in a reaction kettle, after 12 hours of reaction, the obtained product was washed several times with absolute ethanol, several times with deionized water, centrifuged, 40°C vacuum drying;

[0060] (2) Sodium alginate was dissolved in deionized water with a mass percentage of 1.5%, and magnetically stirred for 1 hour;

[0061] (3) Add the prepared nano-magnetic Fe to the above solution 3 o 4 Powder, the mass percentage is 0.01%, electric stirring for 1h;

[0062] (4) Add an ethanol solution of icariin, with a mass percentage of 0.03%, and magnetically stir for 1 hour;

[0063] (5) Using a microcapsule forming device with a voltage of 1.3kv, use a syringe to drop the mixture in step (4) into the gel bath to form primary microspheres;

[0064] (6) Submerge the primary microspheres in a chitosan acetic acid solution with a mass percentage of 0.5% for 12 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com