A processing method for improving surface quality and product yield of sapphire substrate

A surface quality and processing method technology, applied in the field of sapphire substrate surface treatment technology, can solve the problems of affecting production efficiency, low processing efficiency, high fragmentation rate, etc., and achieve the effect of increasing productivity, increasing production efficiency and reducing fragmentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

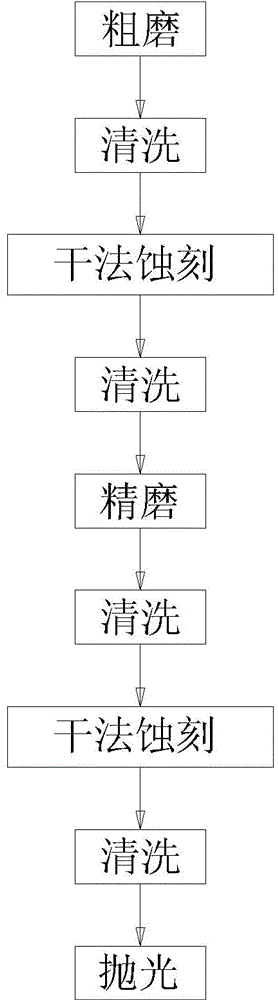

Image

Examples

Embodiment 1

[0025]200 4-inch sapphire substrates after multi-wire cutting were cleaned and roughly ground, divided into 2 groups of 100 pieces, one group was processed by the traditional process, and the other group was processed by the process of the present invention, and the final results were compared.

[0026] The process flow of the present invention: (1) Mechanical fast rough grinding, put the cleaned substrate into the grinding equipment, use 250# boron carbide powder to mix with water according to the concentration ratio of 30% as the grinding liquid, and the grinding speed is 800 rpm, the grinding time is 30 minutes, the removal amount is 90 μm, and the ground substrate is cleaned in an ultrasonic cleaning tank;

[0027] (2) Dry chemical etching to remove stress. Put the cleaned substrate in an 80°C constant temperature oven for 24 hours to dry. After drying, soak in acetone solution to remove residual oil on the surface. After soaking, dry the substrate with a nitrogen gun. Aft...

Embodiment 2

[0033] 200 pieces of 4-inch sapphire substrates after multi-wire cutting were cleaned and roughly ground, and divided into 2 groups, 100 pieces in each group, one group adopts the traditional process, and one group adopts the process of the present invention.

[0034] The process flow of the present invention: (1) Mechanical fast rough grinding, put the cleaned substrate into the grinding equipment, use 260# boron carbide powder to mix with water according to the concentration ratio of 40% as the grinding liquid, and the grinding speed is 900 rpm, the grinding time is 25 minutes, the removal amount is 100 μm, and the ground substrate is cleaned in an ultrasonic cleaning tank;

[0035] (2) Dry chemical etching to remove stress. Put the cleaned substrate in an 80°C constant temperature oven for 24 hours to dry. After drying, soak in acetone solution to remove residual oil on the surface. After soaking, dry the substrate with a nitrogen gun. After blowing dry, put it into a dry e...

Embodiment 3

[0041] 200 pieces of 4-inch sapphire substrates after multi-wire cutting were cleaned and roughly ground, and divided into 2 groups, 100 pieces in each group, one group adopts the traditional process, and one group adopts the process of the present invention.

[0042] The process flow of the present invention: (1) Mechanical fast rough grinding, put the cleaned substrate into the grinding equipment, use 280# boron carbide powder to mix with water according to the concentration ratio of 50% as the grinding liquid, and the grinding speed is 800 rpm, the grinding time is 20 minutes, the removal amount is 110 μm, and the ground substrate is cleaned in an ultrasonic cleaning tank;

[0043] (2) Dry chemical etching to remove stress. Put the cleaned substrate in an 80°C constant temperature oven for 24 hours to dry. After drying, soak in acetone solution to remove residual oil on the surface. After soaking, dry the substrate with a nitrogen gun. After drying, put it into a dry etchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com