Preparation method of graphene dispersion liquid

A graphene dispersion liquid and graphene technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of complex preparation process, limited application, easy agglomeration, etc., and achieve good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

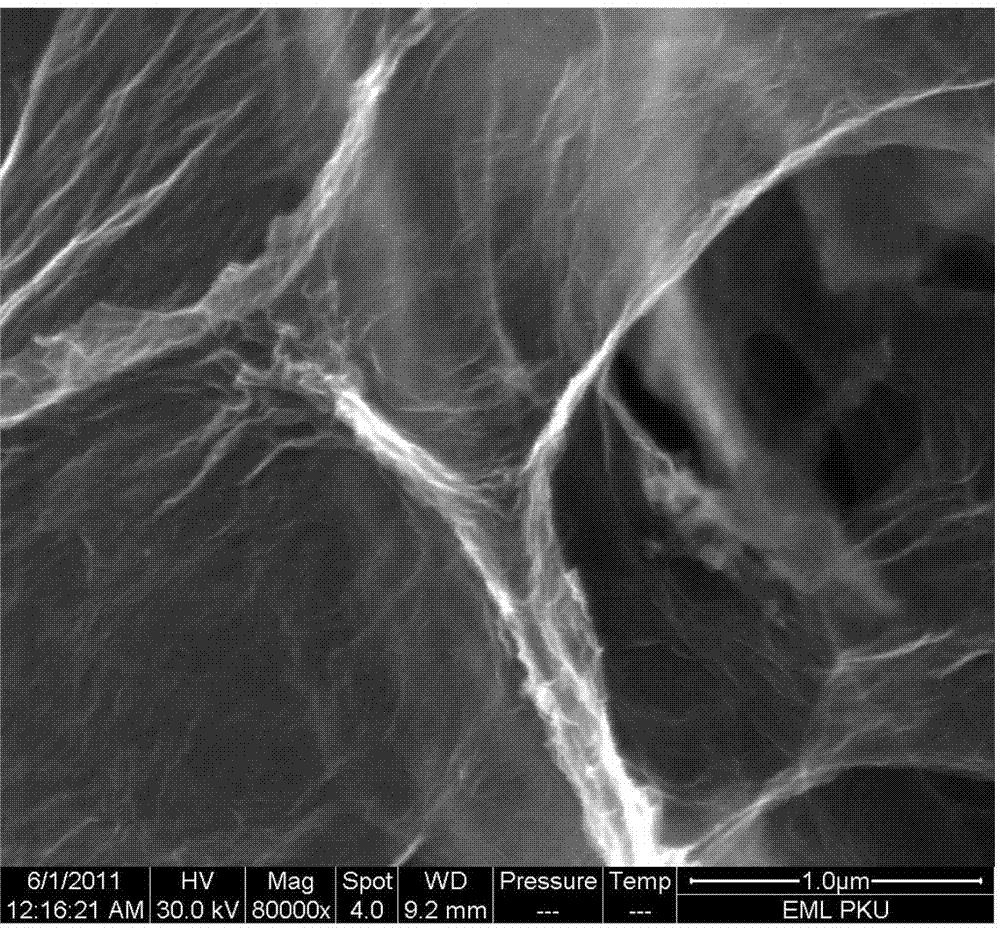

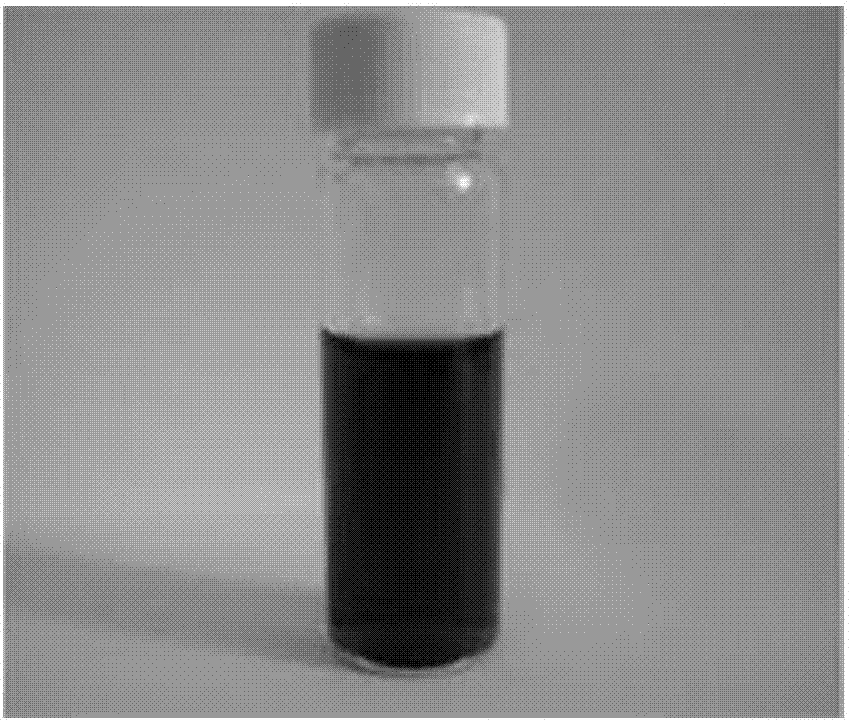

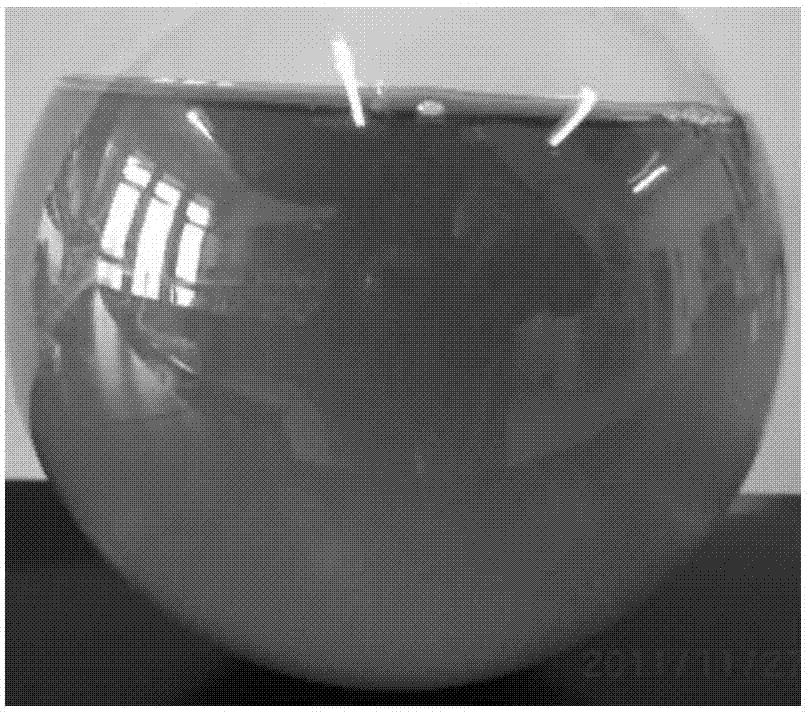

Image

Examples

Embodiment 1

[0020] (1) Weigh 10g of graphene oxide prepared by the Hummers method and disperse it into 1000g of distilled water, disperse evenly through mechanical stirring and ultrasonic oscillation, and perform centrifugation with a centrifuge to obtain a graphene oxide dispersion;

[0021] (2) Add the graphene oxide dispersion obtained in (1) into a high-pressure spray tank, pressurize the graphene oxide dispersion into a liquid nitrogen container, and perform quick freezing at minus 80°C to obtain a graphene oxide dispersion quick-frozen products;

[0022] (3) Weigh 4.5kg of methanol and put it into a 10L reactor, add the quick-frozen product of graphene oxide dispersion to it, and let the system rise to room temperature naturally;

[0023] (4) Add acetic acid to the system of (3) above to adjust the pH of the solution to 4.15;

[0024] (5) Add a total of 5 g of sodium borohydride to the above (4) system at 0.5 g each time, immediately raise the temperature of the system to 60 ° C, a...

Embodiment 2

[0028] (1) Weigh 10g of graphene oxide prepared by the Hummers method and disperse it into 1000g of distilled water, disperse evenly through mechanical stirring and ultrasonic oscillation, and perform centrifugation with a centrifuge to obtain a graphene oxide dispersion;

[0029] (2) Add the graphene dispersion obtained in (1) into a high-pressure spray tank, spray the graphene oxide dispersion into a liquid nitrogen container under pressure, and perform quick-freezing treatment at minus 80°C to obtain a quick-frozen graphene oxide dispersion product;

[0030] (3) Weigh 6.5kg of distilled water and put it into a 10L reaction kettle, add the quick-frozen product of graphene oxide dispersion to it, and let the system rise to room temperature naturally;

[0031] (4) Add potassium hydroxide to the above (3) system to adjust the pH of the solution to 8.31;

[0032] (5) Add a total of 8 g of sodium borohydride to the above (4) system at 0.3 g each time, immediately raise the tempe...

Embodiment 3

[0036] (1) Weigh 10g of graphene oxide prepared by the Hummers method and disperse it in 800g of methanol, disperse evenly through mechanical stirring and ultrasonic oscillation, and perform centrifugation with a centrifuge to obtain a graphene oxide dispersion;

[0037] (2) Add the graphene dispersion obtained in (1) into a high-pressure spray tank, spray the graphene oxide dispersion into a liquid nitrogen container under pressure, and perform quick-freezing treatment at minus 80°C to obtain a quick-frozen graphene oxide dispersion product;

[0038] (3) Weigh 4.5kg of methanol and put it into a 10L reactor, add the quick-frozen product of graphene oxide dispersion to it, and let the system rise to room temperature naturally;

[0039] (4) Add potassium hydroxide to the system of (3) above to adjust the pH of the solution to 10.31;

[0040] (5) Add a total of 15 g of sodium borohydride to the above (4) system at 0.5 g each time, immediately raise the temperature of the system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com