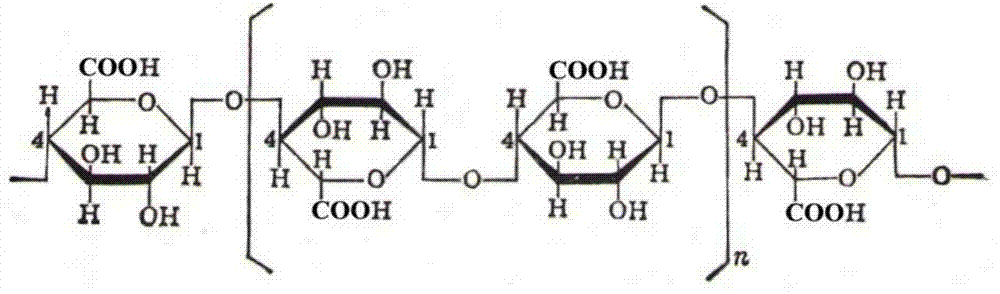

Beta-oligomeric acid, and preparation method and application thereof

An oligomeric acid and oligomerization technology, which is applied in the field of new oligomeric active factor β-oligomeric acid and its preparation, can solve the problems of threat, high loss rate of raw materials, slow research, etc., and achieve enhanced stability, increased production and Quality, the effect of promoting absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, conversion of corn stalk fiber to β-oligomeric acid

[0019] Collect corn stalks and dry them in the sun, crush them into 100 meshes, and after primary separation, take 60 kg and put them into a 2-liter reaction kettle, add 150 kg of composite solvent, heat to 80°C, stir and dissolve, then drop the temperature to 50°C, and add carboxyl 50 kg of carboxylating agent (the carboxylating agent is composed of peracetic acid and sodium nitrite at a weight ratio of 1:1), react for 10 hours, adjust the pH value of the solution to 4.0, filter, spray dry, and the content of β-oligomeric acid in the powder is greater than 10% . The raw material conversion rate is greater than 60%.

Embodiment 2

[0020] Embodiment 2, cotton linter fiber conversion β-oligomeric acid

[0021] Get 80 kilograms of lint, add in 2 liters of reaction kettle, add 200 kilograms of compound solvents, heat to 80 ℃, after stirring and dissolving, the temperature drops to 50 ℃, add carboxylating agent (carboxylating agent is made of peracetic acid, Sodium nitrate, nitrogen weight ratio 1:1:1) 80 kg, react for 6 hours, adjust the pH value of the solution to 4.0, filter, spray dry, and the content of β-oligomeric acid in the powder is greater than 50%. The raw material conversion rate is greater than 80%.

Embodiment 3

[0022] Embodiment 3, rice straw fiber conversion β-oligomeric acid

[0023] Collect rice straw and dry it in the sun, crush it into 60 meshes, and after primary separation, take 60 kg and put it into a 2-liter reaction kettle, add 150 kg of composite solvent, heat to 80°C, stir and dissolve, then drop the temperature to 50°C, add carboxyl 50 kg of carboxylating agent (the carboxylating agent is composed of hydrogen peroxide and sodium nitrite at a weight ratio of 1:1), react for 8 hours, adjust the pH value of the solution to 4.0, filter, spray dry, and the content of β-oligomeric acid in the powder is greater than 30% . The raw material conversion rate is greater than 65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com