Method for preparing biological lubricating oil base oil by using epoxy biodiesel

A technology of epoxy biodiesel and lubricating base oil, which is applied in the direction of biofuel, lubricating composition, base material, etc., can solve the problems of low conversion rate and many side reactions, and meet the requirements of low pollution, simple operation and process equipment not high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

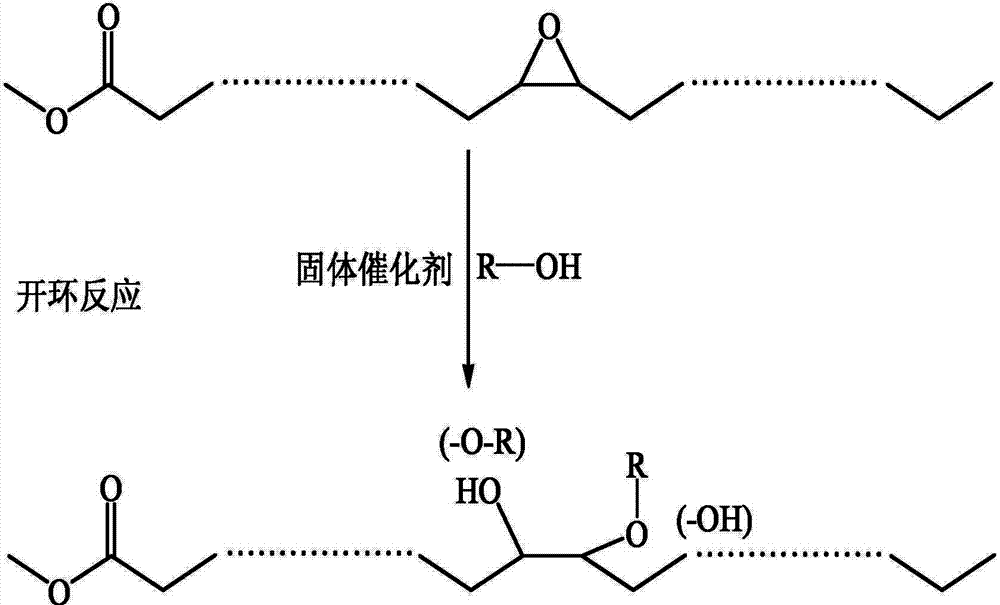

Method used

Image

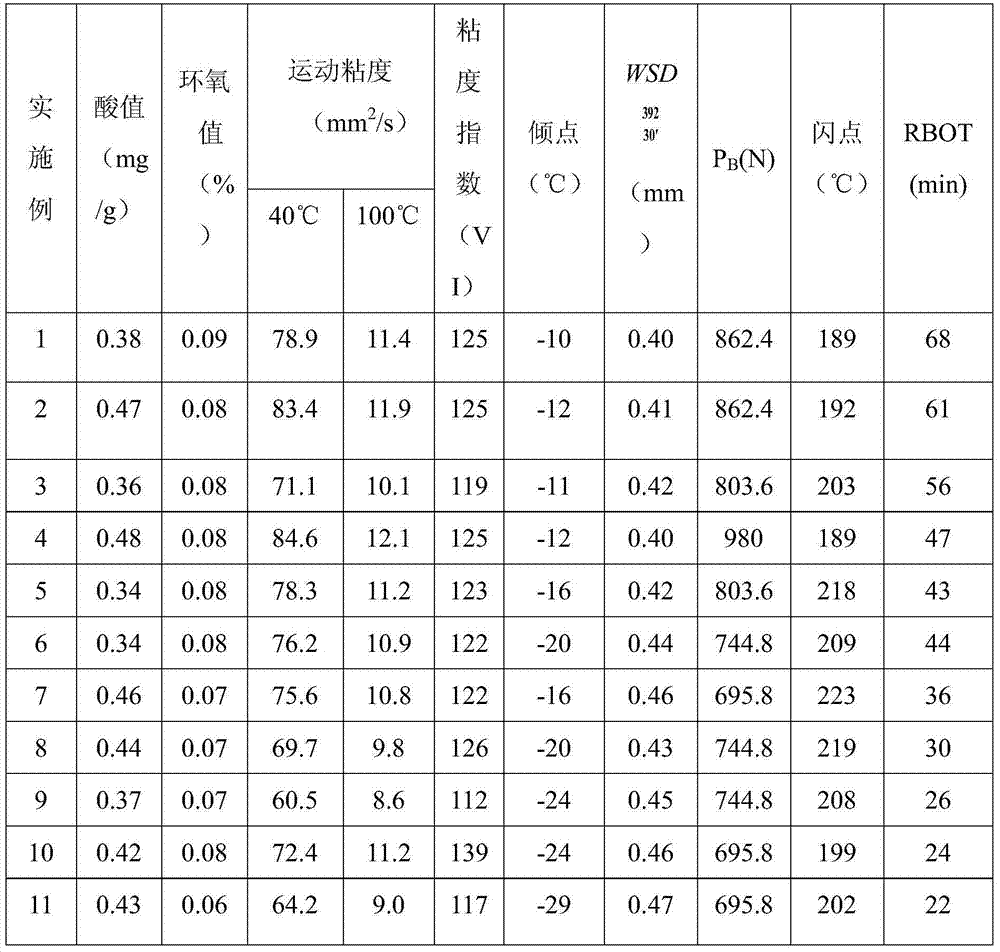

Examples

Embodiment 1

[0028] (1) Isomerization etherification ring-opening reaction: Weigh 90.0g of methanol and 9g of D001 resin supported by cerium sulfate as a solid catalyst (D001(Ce 4+ )) placed in a four-necked flask with a condenser, agitator and a thermometer, stirred, refluxed, and temperature controlled at 35°C, then added 300g of epoxy biodiesel, the epoxy value of which was 5.48, and opened at this temperature Ring reaction, the ultrasonic frequency of the auxiliary ultrasonic equipment is 40KHZ, and the ultrasonic power is 500W. During the reaction process, samples were taken from the four-necked flask every 10 minutes, and the epoxy value was measured. When the epoxy value was less than 0.1, it was the end of the reaction. When the reaction reaches the end point, stop the reaction, cool the reaction mixture to room temperature, wash with distilled water at 40°C, separate the lower aqueous phase and solid catalyst and recover the solid catalyst; then wash the upper organic phase with a...

Embodiment 2

[0033] (1) Isomerization etherification ring-opening reaction: Weigh 120.0g of ethanol and 15g of D001 resin supported by cerium sulfate as a solid catalyst (D001(Ce 4+ )) placed in a four-neck flask with a condenser, agitator and a thermometer, stirred, refluxed, heated to 30°C, then added 300g of epoxy biodiesel, the epoxy value is 5.48, and the ring-opening was carried out at this temperature Response, the ultrasonic frequency of the auxiliary ultrasonic equipment is 40KHZ, and the ultrasonic power is 500W. During the reaction process, samples were taken from the four-necked flask every 10 minutes, and the epoxy value was measured. When the epoxy value was less than 0.1, it was the end of the reaction. When the reaction reaches the end point, stop the reaction, cool the reaction mixture to room temperature, wash with distilled water at 40°C, separate the lower aqueous phase and solid catalyst and recover the solid catalyst; then wash the upper organic phase with alkali and ...

Embodiment 3

[0036] (1) Ring-opening reaction of isomerization etherification: Weigh 195.0g of n-propanol and 24g of aluminum sulfate loaded 732 resin (732(Al 3+ )) put in a four-necked flask with a condenser, agitator and a thermometer, stir, reflux, and heat to 40°C, then add 300g of epoxy biodiesel, the epoxy value is 5.40, and open the ring at this temperature Response, the ultrasonic frequency of the auxiliary ultrasonic equipment is 40KHZ, and the ultrasonic power is 550W. During the reaction process, samples were taken from the four-necked flask every 10 minutes, and the epoxy value was measured. When the epoxy value was less than 0.1, it was the end of the reaction. When the reaction reaches the end point, stop the reaction, cool the reaction mixture to room temperature, wash with distilled water at 40°C, separate the lower aqueous phase and solid catalyst and recover the solid catalyst; then wash the upper organic phase with alkali and water until pH = 7, and then Vacuum dehydrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wear scar diameter | aaaaa | aaaaa |

| Oxidation induction period | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com