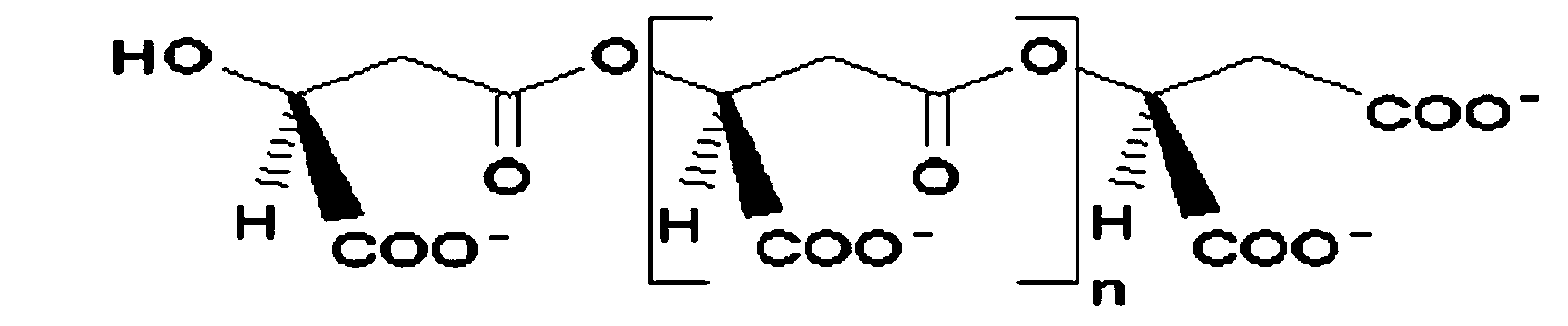

Method for producing polymalic acid of different molecular weights through combined regulation

A technology of polymalic acid and molecular weight, applied in the field of microbial fermentation, can solve the problems of difficult extraction, low purity of β-polymalic acid, high cost of raw materials, etc., and achieve the effect of wide and reasonable application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A fermentation method for producing polymalic acid with different molecular weights, the steps are as follows:

[0025] 1. Composition of fermentation medium: sucrose 120g / L, NaNO 3 2g / L, KH 2 PO 4 0.1g / L, KCl0.4g / L, MnSO 4 0.05g / L, MgSO 4 ·7H 2 O1.0g / L, CaCO 3 20g / L, NH 4 NO 3 14.5g / L, aspartic acid 0.25~0.30g / L, leucine 0.58g / L, threonine 0.25g / L, valine 0.5g / L, histidine 0.35g / L, cytosine 0.001g / L, adenine 0.0015g / L, choline 0.1g / L, the rest is water, and the initial pH is 7.0.

[0026] 2. Activate the Aureobsidium pullulans CGMCC3336 strain for 6-8 hours, that is, transfer it from the sucrose slant medium to a 500ml baffle bottle with a liquid volume of 50ml, and cultivate at a constant temperature of 25°C and 200r / min 72h to prepare the seed solution; the composition of the seed medium is: sucrose 140g / L, yeast extract 3g / L, ammonium sulfate 1g / L, succinic acid 2g / L, corn steep liquor 1g / L, K 2 CO 3 0.4g / L, MgSO4 7H 2 O0.1g / L, KH 2 PO 4 1g / L, ZnSO 4 ...

Embodiment 2

[0030] A fermentation method for producing polymalic acid with different molecular weights, the steps are as follows:

[0031] 1. Composition of fermentation medium: sucrose 120g / L, NaNO 3 2g / L, KH 2 PO 4 0.1g / L, KCl0.4g / L, MnSO40.05g / L, MgSO 4 ·7H 2 O1.0g / L, CaCO 3 20g / L, NH 4 NO 3 14.5g / L, aspartic acid 0.30~0.35g / L, leucine 0.58g / L, threonine 0.25g / L, valine 0.5g / L, histidine 0.35g / L, cytosine 0.001g / L, adenine 0.0015g / L, choline 0.1g / L, the rest is water, and the initial pH is 7.0.

[0032] 2, the preparation of seed liquid and the bacterial classification used are basically the same as embodiment 1; L.K 2 CO 3 0.4g / L, MgSO 4 ·7H 2 O0.1g / L, KH 2 PO41g / L, ZnSO 4 ·7H 2 O0.05g / L, the rest is water, pH7.0.

[0033] 3. Connect the seed liquid obtained in step 2 to a 5L (3L liquid) fermenter at a volume ratio of 10%, with a ventilation rate of 1.0 (V / V), 400r / min, and culture at 25°C for 120h. Sampling in 2 hours, use amino column to detect the content of aspart...

Embodiment 3

[0036] A fermentation method for producing polymalic acid with different molecular weights, the steps are as follows:

[0037] 1. Composition of fermentation medium: sucrose 120g / L, NaNO 3 2g / L, KH 2 PO 4 0.1g / L, KCl0.4g / L, MnSO40.05g / L, MgSO 4 ·7H 2 O1.0g / L, CaCO 3 20g / L, NH 4 NO 3 14.5g / L, aspartic acid 0.35~0.4g / L, leucine 0.58g / L, threonine 0.25g / L, valine 0.5g / L, histidine 0.35g / L, cytosine 0.001g / L, adenine 0.0015g / L, choline 0.1g / L, the rest is water, and the initial pH is 7.0.

[0038] 2, the preparation of seed liquid and the bacterial classification used are basically the same as embodiment 1; L.K 2 CO 3 0.4g / L, MgSO 4 ·7H 2 O0.1g / L, KH 2 PO41g / L, ZnSO 4 ·7H 2 O0.05g / L, the rest is water, pH7.0.

[0039] 3. Connect the seed liquid obtained in step 2 to a 5L (3L liquid) fermenter at a volume ratio of 10%, with a ventilation rate of 1.0 (V / V), 400r / min, and culture at 25°C for 120h. Sampling at 2 hours, using amino column to detect aspartic acid conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com