Preparation method of compound salvia tablets

A technology of compound Danshen tablets and borneol, which is applied in the field of preparation technology of compound Danshen tablets, can solve the problems of long production cycle, unfavorable absorption, high production cost, etc., and achieve the effects of improving production safety, reducing the number of operators, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

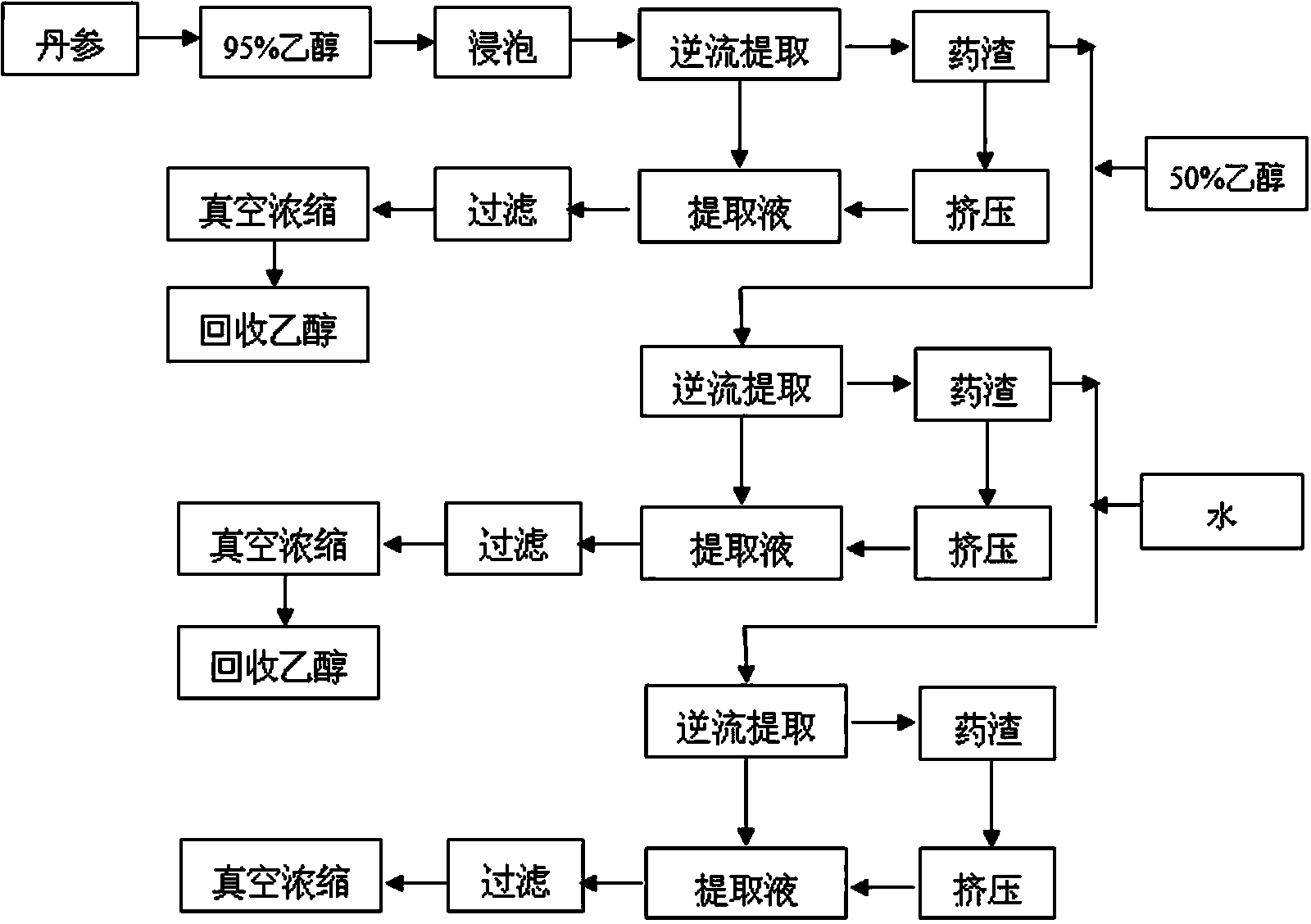

[0021] (1) Put Danshen into the extraction tank, add 6 times the amount of 95% ethanol to the extraction tank and soak for 6 hours, perform the first countercurrent extraction for 1.5 hours, add 50% ethanol to the dregs for the second countercurrent extraction, extract 1.5 hour, add water to the dregs and carry out the third countercurrent extraction for 1.5 hours, see the schematic diagram of the continuous countercurrent extraction process of Salvia figure 1 . (2) Panax notoginseng is pulverized into superfine powder (200-300 mesh), made into granules with the above-mentioned concentrated solution and appropriate amount of auxiliary materials, and dried.

[0022] (3) The borneol is pulverized by an ultra-low temperature pulverizer (180-300 mesh), mixed with the above granules, pressed into tablets, coated with sugar or film, and the product is ready.

Embodiment 2

[0024] (1) Put danshen into the extraction tank, add 5 times the amount of 95% ethanol to the extraction tank, soak for 5 hours, perform the first countercurrent extraction for 1 hour, add 50% ethanol to the dregs for the second countercurrent extraction, and extract 1 hour, add water to the medicinal dregs and carry out the third countercurrent extraction for 1 hour, the schematic diagram of the continuous countercurrent extraction process of Danshen figure 1 .

[0025] (2) Panax notoginseng is crushed into ultrafine powder (200-300 mesh), and then mixed with the above-mentioned concentrated solution and appropriate amount of auxiliary materials to make granules and dried.

[0026] (3) After the borneol is pulverized by an ultra-low temperature pulverizer (180-300 mesh), it is mixed with the above-mentioned granules, pressed into tablets, coated with sugar or film, and the product is ready.

Embodiment 3

[0028] (1) Put Danshen into the extraction tank, add 4 times the amount of 95% ethanol to the extraction tank, soak for 4 hours, perform the first countercurrent extraction for 1.5 hours, add 50% ethanol to the dregs for the second countercurrent extraction, extract 1.5 hour, add water to the dregs and carry out the third countercurrent extraction for 1.5 hours, see the schematic diagram of the continuous countercurrent extraction process of Salvia figure 1 . (2) Panax notoginseng is crushed into ultrafine powder (200-300 mesh), and then mixed with the above-mentioned concentrated solution and appropriate amount of auxiliary materials to make granules and dried.

[0029] (3) After the borneol is pulverized by an ultra-low temperature pulverizer (180-300 mesh), it is mixed with the above-mentioned granules, pressed into tablets, coated with sugar or film, and the product is ready.

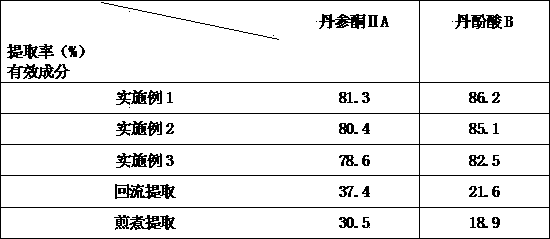

[0030] The continuous countercurrent extraction method of Examples 1 to 3 has a 20%-30% higher ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com