Silica gel with ionic liquid and mercaptan loaded on surface as well as preparation method and application

An ionic liquid and surface-loaded technology, applied in the fields of application, chemical instruments and methods, and other chemical processes, can solve problems such as not being well-known, and achieve obvious effects, simple preparation methods, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Silicone surface activation treatment

[0046] Weigh 100g of silica gel, soak it in pH 3.0 hydrochloric acid solution (500mL) for 24h to generate a large number of hydroxyl groups on the surface of silica gel, then wash repeatedly with deionized water, and then wash with AgNO 3 Solution Detection of Cl in Water Wash - ions until Cl-free - In the presence of ions, dry in the air, and then dry at 150 ° C for 12 hours before use.

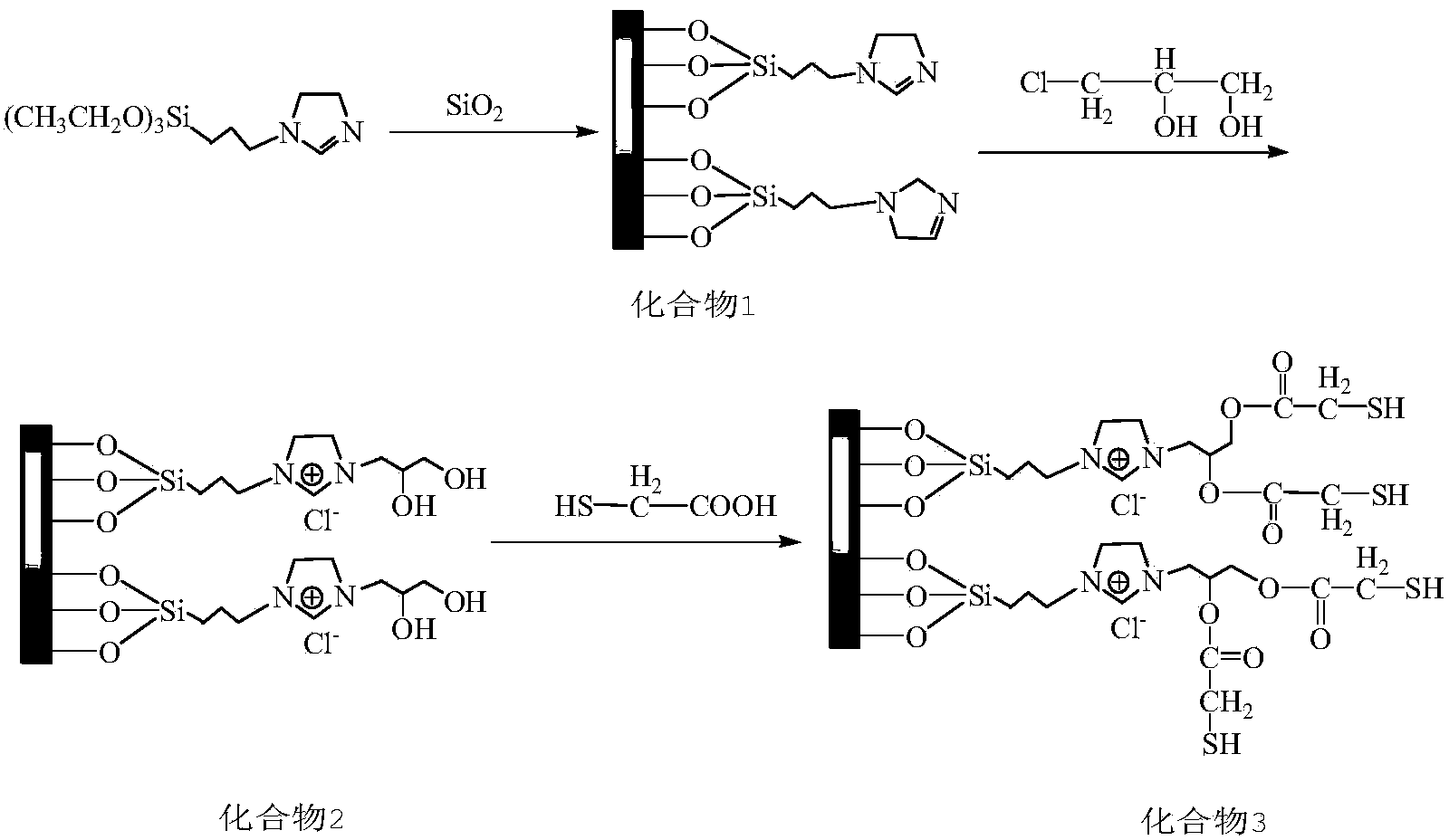

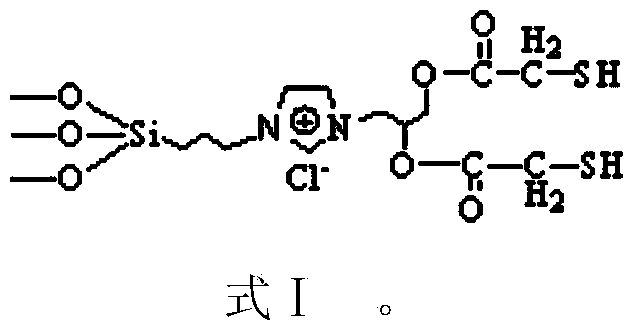

[0047] (2) Preparation of N-propyl-4,5-dihydroimidazole (compound 1) grafted on the surface of silica gel

[0048] Weigh 10 grams of silica gel (SiO 2 ), ultrasonically dispersed in 100mL of anhydrous toluene, and then added dropwise 10.68mmol of N-[3-(triethoxysilyl)propyl]-4,5-dihydroimidazole under the protection of nitrogen, vigorously stirred, in After reacting at 110°C for 24 hours, cool to room temperature, filter and separate the product, wash repeatedly with anhydrous methanol, dry at 80°C for 1 hour, and then dry at 150°C for 1...

Embodiment 2

[0054] (1) Silicone surface activation treatment

[0055] With embodiment 1.

[0056] (2) Preparation of N-propyl-4,5-dihydroimidazole (compound 1) grafted on the surface of silica gel

[0057] Weigh 10 grams of silica gel (SiO 2 ), ultrasonically dispersed in 100mL of anhydrous toluene, and then added dropwise 10.68mmol of N-[3-(triethoxysilyl)propyl]-4,5-dihydroimidazole under the protection of nitrogen, vigorously stirred, in After reacting at 110°C for 24 hours, cool to room temperature, filter and separate the product, wash repeatedly with anhydrous methanol, dry at 80°C for 1 hour, and then dry at 150°C for 12 hours to obtain compound 1 grafted with propylimidazole on the silicon surface.

[0058] (3) Preparation of ionic liquid (compound 2) loaded with 1-(2’,3’-dihydroxypropyl)-imidazolium chloride on the surface of silica gel

[0059] Weigh 10g of N-[3-(triethoxysilyl)propyl]-4,5-dihydroimidazole modified compound 1, ultrasonically disperse it in 100mL of anhydrous ...

Embodiment 3

[0063] (1) Silicone surface activation treatment

[0064] With embodiment 1.

[0065] (2) Preparation of N-propyl-4,5-dihydroimidazole (compound 1) grafted on the surface of silica gel

[0066] Weigh 10 grams of silica gel (SiO 2 ), ultrasonically dispersed in 100mL of anhydrous toluene, and then added dropwise 10.68mmol of N-[3-(triethoxysilyl)propyl]-4,5-dihydroimidazole under the protection of nitrogen, vigorously stirred, in After reacting at 110°C for 24 hours, cool to room temperature, filter and separate the product, wash repeatedly with anhydrous methanol, dry at 80°C for 1 hour, and then dry at 150°C for 12 hours to obtain compound 1 grafted with propylimidazole on the silicon surface.

[0067] (3) Preparation of ionic liquid (compound 2) loaded with 1-(2’,3’-dihydroxypropyl)-imidazolium chloride on the surface of silica gel

[0068] Weigh 10g of N-[3-(triethoxysilyl)propyl]-4,5-dihydroimidazole modified compound 1, ultrasonically disperse it in 100mL of anhydrous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com