Sulfur-doped nano ferroferric oxide/biochar composite material as well as preparation method and application thereof

A technology of ferroferric oxide and composite materials, which is applied in the field of sulfur-doped nanometer ferroferric oxide/biochar composite materials and its preparation and application, can solve problems such as inability to solve remediation problems and difficult to achieve soil remediation goals, and achieve Maintain magnetic separation characteristics, efficiently adsorb heavy metals, and have a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: Preparation of sulfur-doped nano-ferric oxide / biochar composite material

[0041] Step 1: Wash the mung bean shell, the raw material of biomass, dry at 80° C. for 48 hours, and pass through a 10-mesh sieve after crushing. The processed mung bean shell raw material is put into a tube furnace, and oxygen is isolated under the protection of nitrogen. The temperature rise program is set at 15°C / min to raise the temperature to 700°C, and it is pyrolyzed at 700°C for 2 hours under oxygen-limited conditions, and finally cooled to obtain biochar.

[0042] Step 2: Grind the biochar obtained above, pass through a 100-mesh sieve, and set aside.

[0043] Step 3: ultrasonically disperse 60mmol of thiourea, 20mmol of ferric nitrate nonahydrate and an appropriate amount of biochar in 50mL of n-butylamine for 30min, respectively. First, mix thiourea and ferric nitrate nonahydrate solution in a 250mL three-necked flask, and react the mixed solution at 60°C for 30min under...

Embodiment 2

[0045] Embodiment 2: Preparation of sulfur-doped nano-ferric oxide / biochar composite material

[0046] Step 1: Dry the water hyacinth root powder at 80°C for 48h as a biomass raw material, put it into a tube furnace, set the temperature rise program at 15°C / min to raise the temperature to 700°C, pyrolyze it at 700°C for 2h under oxygen-limited conditions, and finally cool down to obtain biochar .

[0047] Step 2: Grind the biochar obtained above, pass through a 100-mesh sieve, and set aside.

[0048] Step 3: ultrasonically disperse 60 mmol of thiourea, 20 mmol of ferric nitrate nonahydrate and an appropriate amount of biochar in 50 mL of n-butylamine for 30 min, respectively. First, mix thiourea and ferric nitrate nonahydrate solution in a 250mL three-necked flask, and react the mixed solution at 60°C for 30min under the protection of continuous stirring and inert gas. Then the biochar suspension was added, and the reaction was continued for 2 h. After removing the heat sou...

Embodiment 3

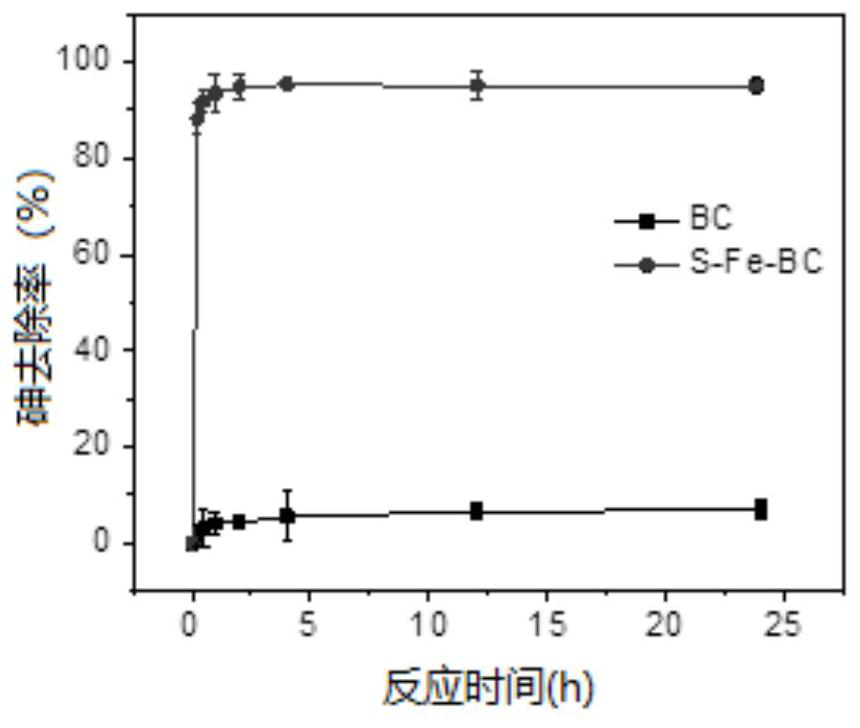

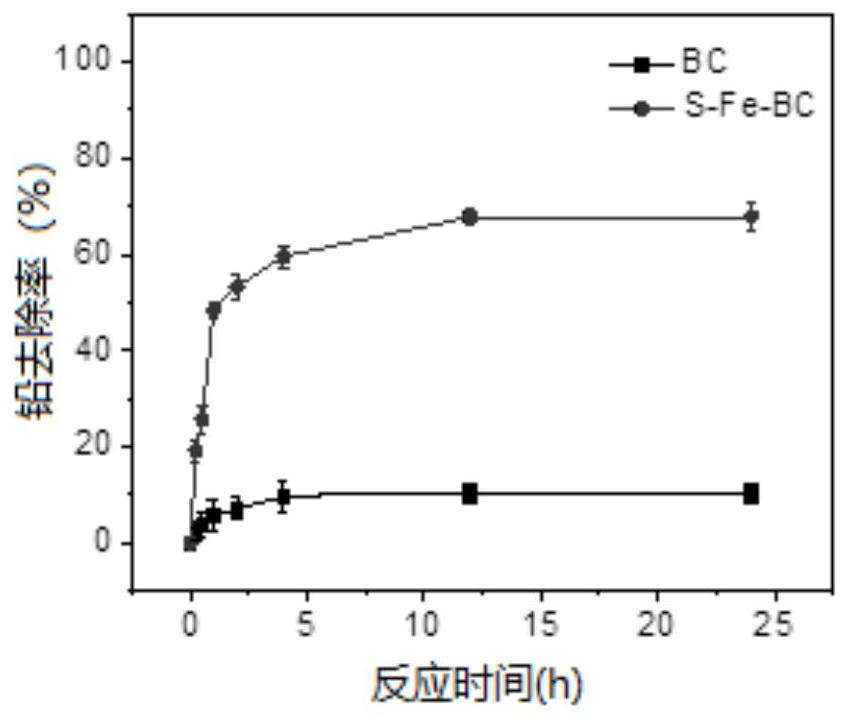

[0050] Example 3: Determination of the removal performance of heavy metal arsenic and lead in soil by sulfur-doped nano-ferric oxide / biochar composite material

[0051] Soil remediation experiment (conducted in an air environment): Measure 10mL of deionized water and add it to an Erlenmeyer flask containing 2g of contaminated soil, shake well, then add 0.02g of the prepared sample, and shake in a water bath for 12h. Each sampling volume is 1ml, and after filtering through a 0.45 μm filter membrane, use an atomic absorption spectrophotometer and an atomic fluorescence spectrometer to measure the concentrations of Pb and As therein, and calculate the removal rate.

[0052] Figure 1a and Figure 1b Respectively, the sulfur-doped iron ferric oxide nanomaterials involved in Example 2 of the present invention remove arsenic and lead from soil. From Figure 1a and Figure 1b It can be seen that the removal rate of arsenic in soil to the sulfur-doped nano ferric oxide / biochar compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com