Preparation method of catalyst for catalytic oxidation of ammonia (NH3)

A catalytic oxidation and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of complicated preparation process, high cost, high conversion temperature, etc. Achieve the effect of low price, outstanding low temperature activity, and high N2 selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Catalytic oxidation of NH described in this example 3 The preparation method of catalyst, comprises the steps:

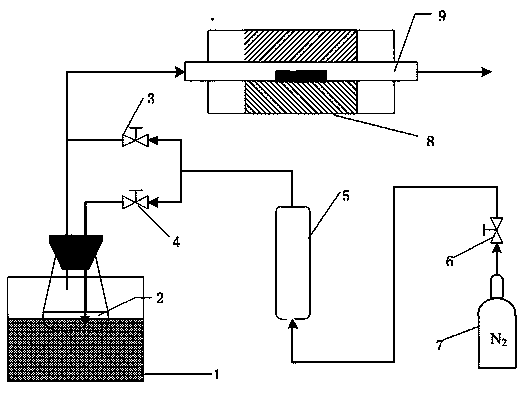

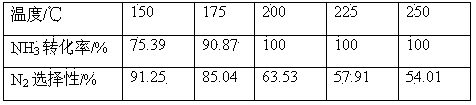

[0022] (1) will be loaded with 5 grams of nano-TiO 2 Put the powdered quartz tube 9 in the tube furnace 8, put the Erlenmeyer flask 2 filled with absolute ethanol into the water bath 1, set the temperature of the water bath to 70°C, open the valve III 6, and feed in N 2 , N 2 The flow rate is 300mL / min, ventilate for 20min, start the tube furnace 8, when the temperature reaches 600°C, open the valve II4 and close the valve I3, at this time, N 2 Continuously bring anhydrous ethanol vapor into the reaction area, after 20 minutes of reaction, close Ⅱ4, open valve Ⅰ3, N 2 The atmosphere dropped to room temperature, closed the valve III 6, and took out the product. The obtained product was placed in a beaker filled with 150 mL of concentrated nitric acid with a mass fraction of 80%, and stirred for 5-10 min. Ultrasonic treatment for 60 minutes, suction filtrat...

Embodiment 2

[0030] Catalytic oxidation of NH described in this example 3 The preparation method of catalyst, comprises the steps:

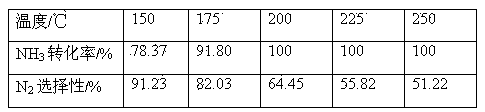

[0031] (1) will be loaded with 5 grams of nano-TiO 2 Put the powdered quartz tube 9 in the tube furnace 8, put the Erlenmeyer flask 2 filled with absolute ethanol into the water bath 1, set the temperature of the water bath to 80°C, open the valve III 6, and feed in N 2 , N 2 The flow rate is 300mL / min, ventilate for 60min, start the tube furnace 8, when the temperature reaches 500°C, open the valve II4 and close the valve I3, at this time, N 2 Continuously bring anhydrous ethanol vapor into the reaction area, after 90 minutes of reaction, close Ⅱ4, open valve Ⅰ3, N 2 The atmosphere dropped to room temperature, closed the valve III 6, took out the product, placed the obtained product in a beaker filled with 150mL of concentrated nitric acid with a mass fraction of 72%, stirred for 10min, and then ultrasonicated under the condition of ultrasonic power of 28...

Embodiment 3

[0039] Catalytic oxidation of NH described in this example 3 The preparation method of catalyst, comprises the steps:

[0040] (1) will be loaded with 5 grams of nano-TiO 2 Put the powdered quartz tube 9 in the tube furnace 8, put the Erlenmeyer flask 2 filled with absolute ethanol into the water bath 1, set the temperature of the water bath to 75°C, open the valve III 6, and feed in N 2 , N 2 The flow rate is 150mL / min, ventilate for 30min, start the tube furnace 8, when the temperature reaches 550°C, open the valve II4 and close the valve I3, at this time, N 2 Continuously bring anhydrous ethanol vapor into the reaction area, after 45 minutes of reaction, close Ⅱ4, open valve Ⅰ3, N 2 The atmosphere dropped to room temperature, closed the valve III 6, took out the product, placed the obtained product in a beaker filled with 150mL of concentrated nitric acid with a mass fraction of 80%, stirred for 7min, and then ultrasonicated under the condition of ultrasonic power of 45H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com