Sulfonated coal loaded TiO2 photocatalyst and preparation method thereof

A technology of photocatalyst and sulfonated coal, which is applied in the direction of physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, chemical instrument and method, etc. It can solve the problem of reducing specific surface area, fine particle specific gravity, and not easy to settle and other problems, to achieve the effect of strong photocatalytic performance, simple equipment requirements, and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

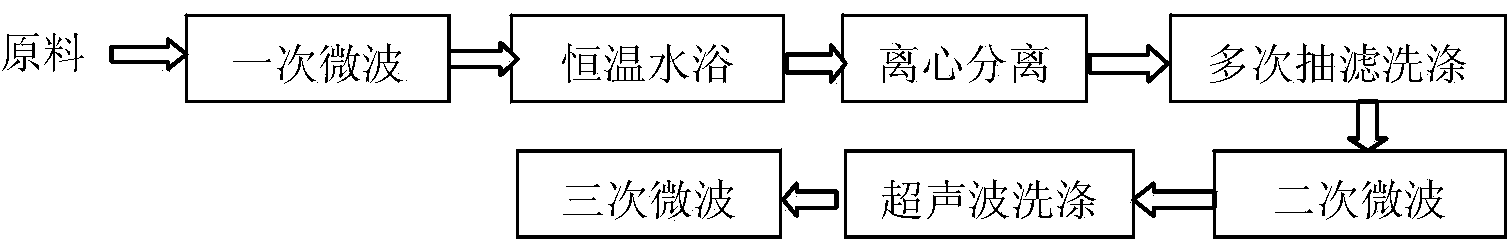

[0032] Such as figure 1 As shown, semi-coke sulfonated coal loaded TiO 2 The photocatalyst preparation process mainly includes: one microwave, constant temperature water bath, centrifugal separation, multiple suction filtration and washing, two microwaves, ultrasonic washing, three microwaves.

[0033] Experimental procedure: add 12g of washed semi-coke sulfonated coal (mass ratio of semi-coke sulfonated coal to solution solute is 1:2.5) 0.15mm-0.3mm semi-coke sulfonated coal into pH=2 sulfuric acid solution dissolved with 30g titanium sulfate (solution concentration 0.1g / mL), stir well, add concentrated ammonia water dropwise until the pH of the mixture is 5-6, after stirring evenly, place the reaction kettle in a modified microwave experimental furnace with a reflux and stirring device, at power P =530W under the condition of microwave irradiation for 1h for the first time, then put the reaction kettle in a constant temperature water bath at 90°C for 11h, centrifuge, wash wi...

Embodiment 2

[0036] Add 3g of washed semi-coke sulfonated coal (mass ratio of semi-coke sulfonated coal to solution solute is 1:10) 0.15mm ~ 0.3mm semi-coke sulfonated coal into pH=2 sulfuric acid solution dissolved with 30g titanium sulfate (solution concentration is 0.2g / L), stir fully, add concentrated ammonia water dropwise until the pH of the mixture is 5-6, and after stirring evenly, place the reaction kettle in a modified microwave experimental furnace with a reflux and stirring device, in a power P=690W Under the conditions of microwave radiation for 75 minutes for the first time, then the reaction kettle was placed in a constant temperature water bath at 95°C for 10 hours, centrifuged, washed with deionized water and absolute ethanol and suction filtered, and the obtained filter cake was put into a microwave experimental furnace. Dry under the same conditions for 45 minutes. After the sample is microwaved again, use an ultrasonic cleaner to vibrate and wash for 20 minutes at 100 H...

Embodiment 3

[0039] Add 12g of washed semi-coke sulfonated coal (mass ratio of semi-coke sulfonated coal to solution solute is 1:2.5) 0.15mm ~ 0.3mm semi-coke sulfonated coal into pH=2 sulfuric acid solution dissolved with 30g titanium sulfate (solution concentration is 0.1g / mL), stir well, add concentrated ammonia water dropwise until the pH of the mixture is 5-6, after stirring evenly, place the reaction kettle in a modified microwave experimental furnace with a reflux and stirring device, under a power P=530W Under the conditions of microwave radiation for 1 hour for the first time, the reaction kettle was then placed in a constant temperature water bath at 90°C for 10 hours, centrifuged, washed with deionized water and absolute ethanol and suction filtered, and the obtained filter cake was put into a microwave experimental furnace. Dry under the same conditions for 45 minutes. After the sample is microwaved again, it is washed with an ultrasonic cleaner at 100 Hz for 30 minutes, filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com