Bio-remediation method of hexachlorobenzene-contaminated soil

A technology for contaminated soil and bioremediation, applied in the field of soil remediation, can solve the problems of secondary pollution chemical remediation method reaction conditions, long bioremediation technology restoration time, poor engineering feasibility, etc., achieving strong engineering feasibility and easier to be degraded by microorganisms , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

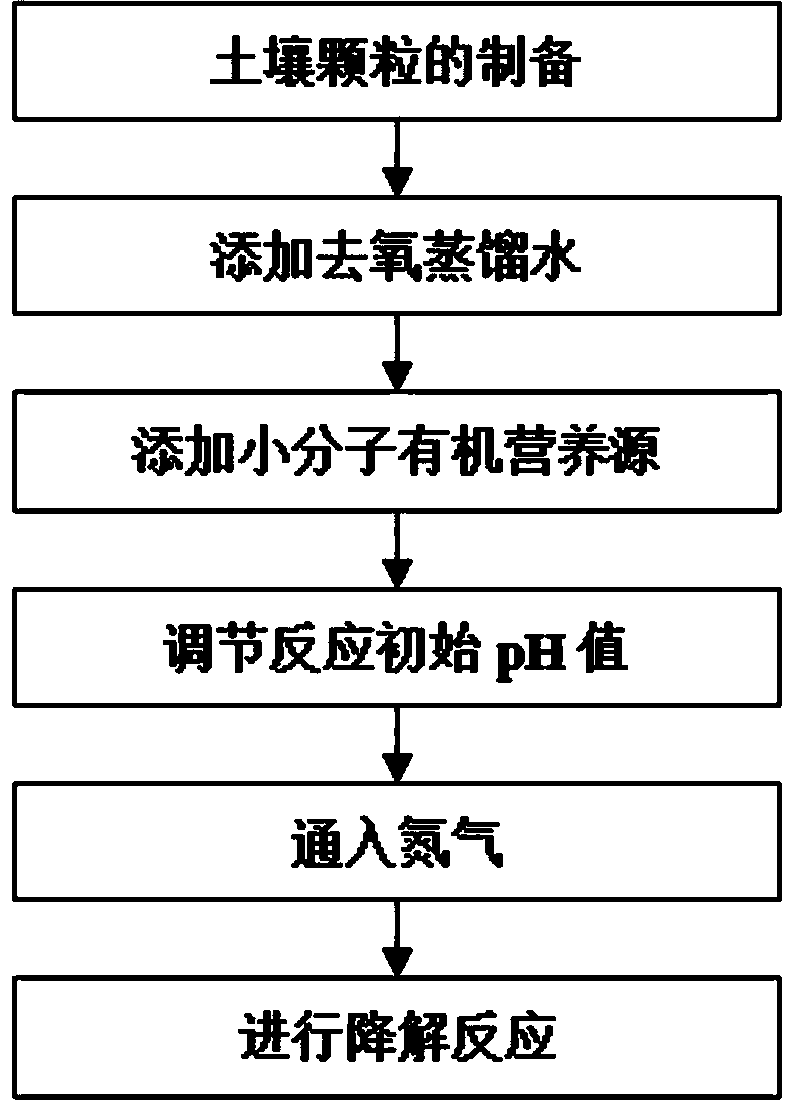

Method used

Image

Examples

example 1

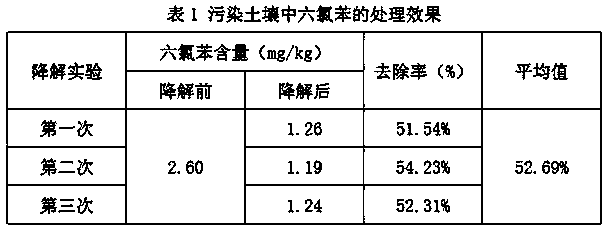

[0027] For contaminated soil with a hexachlorobenzene concentration of 2.6mg / kg, the treatment steps are as follows:

[0028] 1. Air-dry the contaminated soil, crush and grind it through a 2mm sieve twice to ensure that the soil is fully mixed;

[0029] 2. Take 2000g of sieved polluted soil sample, place it in a well-sealed slurry reactor, add 2000ml of distilled water and 8g of acetic acid;

[0030] 3. Use a vacuum pump to evacuate the above-mentioned reaction vessel, then slowly introduce nitrogen, then evacuate again, and then slowly fill with nitrogen, repeat this three times until the reaction vessel is an oxygen-free environment, and then quickly seal the reaction vessel;

[0031] 4. Put the sealed mud reactor in a light-proof environment, and let it stand at a reaction temperature of 45°C for 18 days;

[0032] 5. Separating the mixed slurry after the reaction from solid to liquid, and analyzing and detecting the hexachlorobenzene in the mud sample.

[0033] Table 1 sh...

example 2

[0036] For contaminated soil with a hexachlorobenzene concentration of 2.06mg / kg, the treatment steps are as follows:

[0037] 1. Air-dry the contaminated soil, crush and grind it through a 2mm sieve twice to ensure that the soil is fully mixed;

[0038] 2. Take 2000g of sieved polluted soil samples, place them in a well-sealed slurry reactor, add 2000ml of distilled water and 16g of acetic acid, and adjust the initial pH value of the reaction system to 5;

[0039] 3. Use a vacuum pump to evacuate the above-mentioned reaction vessel, then slowly introduce nitrogen, then evacuate again, and then slowly fill with nitrogen, repeat this three times until the reaction vessel is an oxygen-free environment, and then quickly seal the reaction vessel;

[0040] 4. Put the sealed mud reactor in a light-proof environment, and let it stand at a reaction temperature of 45°C for 18 days;

[0041] 5. Separating the mixed slurry after the reaction from solid to liquid, and analyzing and detec...

example 3

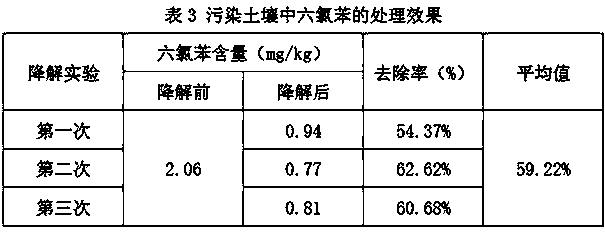

[0045] For contaminated soil with a hexachlorobenzene concentration of 2.06mg / kg, the treatment steps are as follows:

[0046] 1. Air-dry the contaminated soil, crush and grind it through a 2mm sieve twice to ensure that the soil is fully mixed;

[0047] 2. Take 2000g of sieved polluted soil sample, place it in a well-sealed mud reactor, add 2000ml of distilled water and 32g of acetic acid, and adjust the initial pH value of the reaction system to 6;

[0048] 3. Use a vacuum pump to evacuate the above-mentioned reaction vessel, then slowly introduce nitrogen, then evacuate again, and then slowly fill with nitrogen, repeat this three times until the reaction vessel is an oxygen-free environment, and then quickly seal the reaction vessel;

[0049] 4. Put the sealed mud reactor in a light-proof environment, and let it stand at a reaction temperature of 45°C for 18 days;

[0050] 5. Separating the mixed slurry after the reaction from solid to liquid, and analyzing and detecting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com