Pretreatment method for pig farm anaerobic digested liquid

A technology of anaerobic digestion and pretreatment, applied in the field of water treatment, can solve the problems of poor biodegradability, difficult to achieve operation effect of industrialized aerobic biodegradation process, etc., and achieve the effect of good effect, low investment and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

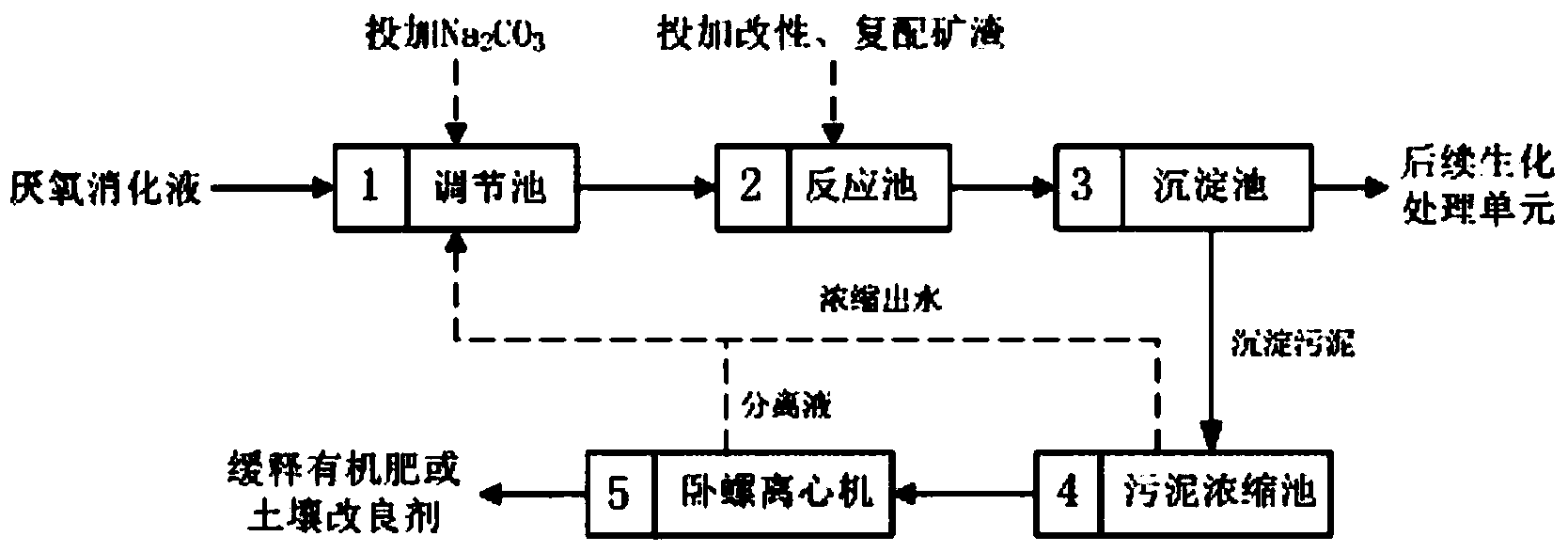

[0018] This embodiment processes pig farm anaerobic digestate 80m 3 .

[0019] Pig farm anaerobic digestion solution original pH=7-7.5, COD concentration 2065.35mg / L, PO 4 3- -P concentration 19.75mg / L, NH 4 + -N concentration 450.22mg / L. The specific implementation steps are as follows: the anaerobic digestion solution in the biogas digester is first collected through the pipeline to the adjustment tank 1 for mixing and homogenization, and sodium carbonate solution is added to adjust the pH of the digestion solution to 9.5; the effluent flows into the reaction tank 2 by 1L : 14.25g of slag powder 1140kg evenly added to the pool after baking, grinding, compounding, baking temperature 110 ℃, baking time 5h, grinding particle size to 200 mesh, compounding ratio is 800kg slag powder: 180kg diphosphate Potassium hydrogen: 160kg magnesium sulfate, combined with the aerator set at the bottom to uniformly aerate the digestive liquid, the aeration time is 2h; the reaction effluen...

Embodiment 2

[0021] This embodiment handles pig farm anaerobic digestate 100m 3 .

[0022] Pig farm anaerobic digestion solution original pH=7-7.5, COD concentration 2065.35mg / L, PO 4 3- -P concentration 19.75mg / L, NH 4 + -N concentration 450.22mg / L. The specific implementation steps are as follows: the anaerobic digestion solution in the biogas digester is first collected through the pipeline to the adjustment tank 1 for mixing and homogenization, and sodium carbonate solution is added to adjust the pH of the digestion solution to 9.5; the effluent flows into the reaction tank 2 by 1L : The ratio of 14.25g is evenly added to the pool after baking, grinding and compounding 1425kg of slag powder, the baking temperature is 110°C, the baking time is 5h, the grinding particle size is 200 mesh, and the compounding ratio is 1000kg slag powder: 225kg diphosphate Potassium hydrogen: 200kg magnesium sulfate, combined with the aerator set at the bottom to uniformly aerate the digestive liquid, ...

Embodiment 3

[0024] This embodiment handles pig farm anaerobic digestate 50m 3 .

[0025] Pig farm anaerobic digestion solution original pH=7-7.5, COD concentration 2065.35mg / L, PO 4 3- -P concentration 19.75mg / L, NH 4 +-N concentration 450.22mg / L. The specific implementation steps are as follows: the anaerobic digestion solution in the biogas digester is first collected through the pipeline to the adjustment tank 1 for mixing and homogenization, and sodium carbonate solution is added to adjust the pH of the digestion solution to 9.5; the effluent flows into the reaction tank 2 by 1L : The ratio of 14.25g is evenly added to the pool after baking, grinding and compounding 712.5kg of slag powder, the baking temperature is 110°C, the baking time is 5h, the grinding particle size is 200 mesh, and the compounding ratio is 500kg. Slag powder: 112.5kg Potassium dihydrogen phosphate: 100kg magnesium sulfate, combined with the aerator set at the bottom to uniformly aerate the digestive liquid,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com