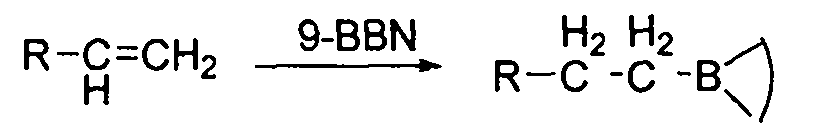

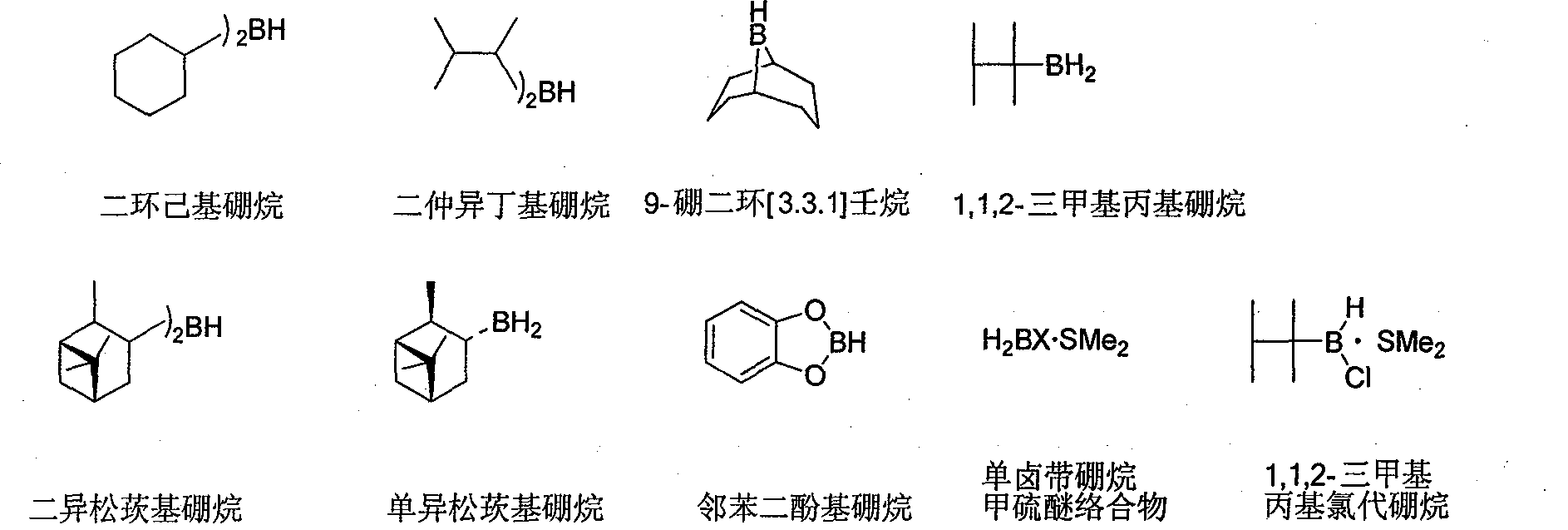

Preparation method of 9-boron bicyclo (3,3,1)-nonane (9-BBN)

A technology of 9-BBN and nonane, which is applied in the field of preparation of 9-boronbicyclo-nonane, can solve the problems that the preparation method is not easy to realize industrialized large-scale production, and achieve the advantages of shortening the product synthesis cycle, good application prospects, and facilitating industrialization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

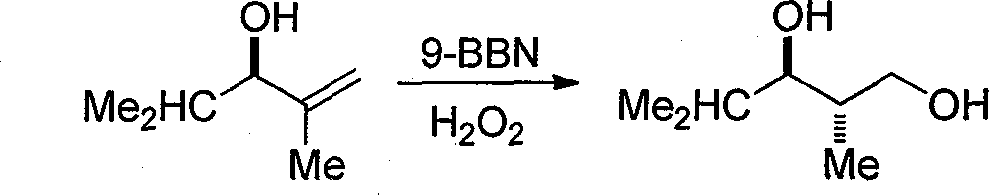

Method used

Image

Examples

Embodiment example 1

[0031] Under the protection of nitrogen, add 10g of crushed 4A molecular sieve, 100ml of solvent tetrahydrofuran, 12.3ml of 1,5-cyclooctadiene and 0.23g of zirconium tetrachloride in a 250ml reaction flask equipped with a reflux device, and magnetically stir at room temperature for 1 hour to make The reactants are evenly mixed, and the reaction solvent and trace water in the raw materials are removed. Cool down to about 0℃, add 10ml of 10M / L borane dimethyl sulfide complex dropwise at a rate of 1 drop per second. After the dropwise addition is complete, heat and reflux for 4 hours, take samples, and detect the isomer 9-boron by GC Bicyclo(4,2,1)-nonane is completely converted into 9-boronbicyclo(3,3,1)-nonane, stop heating, cool the obtained product to 0℃, continue stirring, keep it for 3 hours, It was filtered under the protection of nitrogen to obtain 11.9 g of crystalline solid with a yield of 98.0%.

Embodiment example 2

[0033] Under the protection of nitrogen, add 10g of crushed 4A molecular sieve, 100ml of solvent tetrahydrofuran, 12.3ml of 1,5-cyclooctadiene and 0.23g of zirconium tetrachloride in a 500ml reaction flask equipped with a reflux device, and magnetically stir at room temperature for 1 hour to make The reactants are evenly mixed, and the reaction solvent and trace water in the raw materials are removed. Cool down to about 0°C, add 100ml of 1M / L borane dimethyl sulfide complex at a rate of 5 drops per second. After the addition is complete, heat and reflux for 4 hours, take samples, and detect the isomer 9-boron by GC Bicyclo(4,2,1)-nonane is completely converted into 9-boronbicyclo(3,3,1)-nonane, stop heating, cool the obtained product to 0℃, continue stirring, keep it for 3 hours, It was filtered under the protection of nitrogen to obtain 11.6 g of crystalline solid with a yield of 95.2%.

Embodiment example 3

[0035] Under the protection of nitrogen, add 10g of crushed 4A molecular sieve, 100ml of 1,4-dioxane solvent, 12.3ml of 1,5-cyclooctadiene and 1.1g of zirconium tetrachloride into a 500ml reaction flask equipped with a reflux device in sequence, at room temperature Magnetic stirring is applied for 1 hour to make the reactants mix uniformly and remove trace water in the reaction solvent and raw materials. Cool down to about 0℃, add 10ml of 10M / L borane dimethyl sulfide complex dropwise at a rate of 1 drop per second. After the dropwise addition is complete, heat and reflux for 4 hours, take samples, and detect the isomer 9-boron by GC Bicyclo(4,2,1)-nonane is completely converted into 9-boronbicyclo(3,3,1)-nonane, stop heating, cool the obtained product to 0℃, continue stirring, keep it for 3 hours, It was filtered under the protection of nitrogen to obtain 11.8 g of crystalline solid with a yield of 96.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com