Liquid crystal elastomer composite material for optical actuator and preparation method thereof

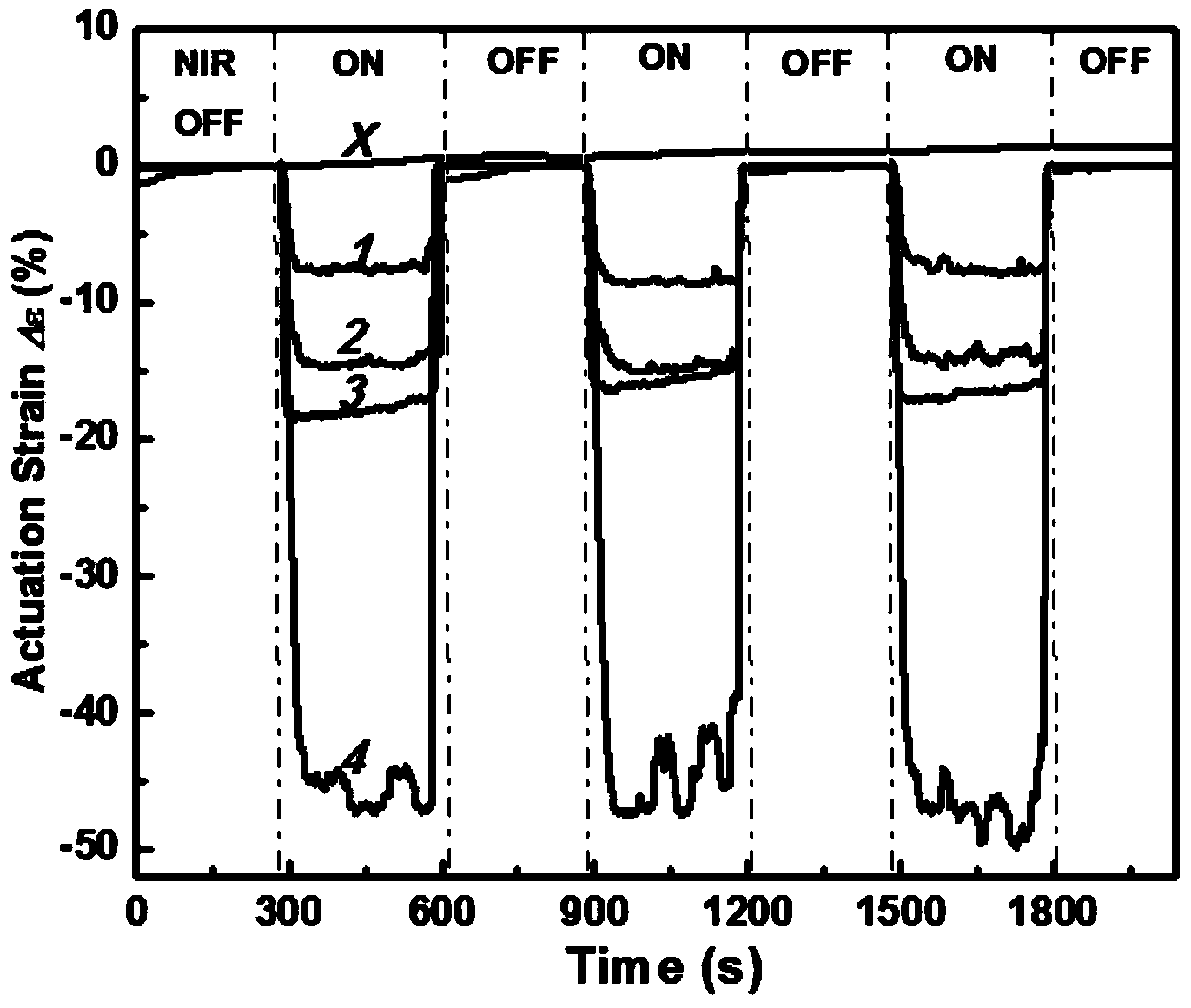

A technology of liquid crystal elastomers and composite materials, applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of slow response rate, small deformation, difficult remote control, etc. fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

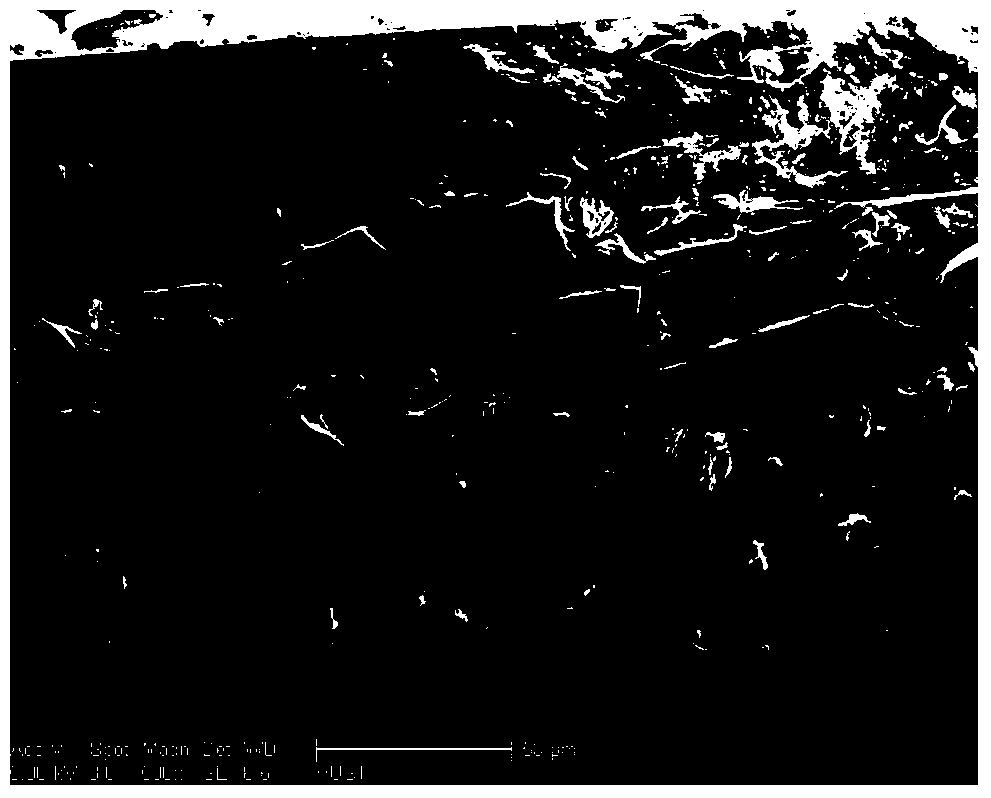

[0046] 1) Add graphene oxide (0.31mg) into 5mL acetone for ultrasonic treatment, then add 2,5-bis(4′-butoxybenzoyloxy)-4″-benzoyloxybutyl- 1-Acrylic liquid crystal monomer (0.1g), 1,6-hexanediol diacrylate crosslinking agent (4mg) and Irgacure369 photoinitiator (0.32mg), continue to stir to obtain a black dispersion liquid;

[0047] 2) Spin-coat the dispersion on a PTFE sheet with a smooth surface, then slowly raise the temperature to 100°C in a dark and nitrogen atmosphere, keep it warm for 10 minutes, then slowly cool down to 80°C, and immediately irradiate it with 365nm light for 15 minutes, and then The temperature was raised to 90°C and irradiated for 15 minutes, and the reaction was completed to obtain a liquid crystal elastomer composite film containing 0.3wt% graphene oxide.

Embodiment 2

[0049] 1) Add graphene (0.31mg) into 5mL acetone for ultrasonic treatment, then add 2,5-bis(4′-butoxybenzoyloxy)-4″-benzoyloxybutyl-1 -Acrylic liquid crystal monomer (0.1g), 1,6-hexanediol diacrylate crosslinker (4mg) and Irgacure369 photoinitiator (0.32mg), continue stirring to obtain a black dispersion liquid;

[0050] 2) Spin-coat the dispersion on a PTFE sheet with a smooth surface, then slowly raise the temperature to 100°C in a dark and nitrogen atmosphere, keep it warm for 10 minutes, then slowly cool down to 80°C, and immediately irradiate it with 365nm light for 15 minutes, and then The temperature was raised to 90°C and irradiated for 15 minutes, and the reaction was completed to obtain a liquid crystal elastomer composite film containing 0.3wt% graphene.

Embodiment 3

[0052] 1) Add carbon nanotubes (0.31 mg) to 5 mL of acetone for ultrasonic treatment, then add 2,5-bis(4′-butoxybenzoyloxy)-4″-benzoyloxybutyl- 1-Acrylic liquid crystal monomer (0.1g), 1,6-hexanediol diacrylate crosslinking agent (4mg) and Irgacure369 photoinitiator (0.32mg), continue to stir to obtain a black dispersion liquid;

[0053] 2) Spin-coat the dispersion on a PTFE sheet with a smooth surface, then slowly raise the temperature to 100°C in a dark and nitrogen atmosphere, keep it warm for 10 minutes, then slowly cool down to 80°C, and immediately irradiate it with 365nm light for 15 minutes, and then The temperature was raised to 90° C. and irradiated for 15 minutes, and the reaction was completed to obtain a liquid crystal elastomer composite film containing 0.3 wt % carbon nanotubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com