Preparation method of demulsifier for super and ultra-thick oil

A demulsifier and super-heavy oil technology, applied in the field of polymer material preparation, can solve the problems of serious emulsification of produced fluid, long dehydration time, and difficulty in demulsification, and achieve a neat oil-water interface, fast dehydration speed, and small dosage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Add 600kg of phenol into the reaction equipment, add 600kg of methanol as a solvent, then add 18kg of hydrochloric acid as a catalyst, add 100kg of glyoxal dropwise at 60-80°C, and control the temperature and speed of dropping. After the reaction is completed, 6 kg of potassium hydroxide is added for neutralization, and the pH value is adjusted to 6-7 to obtain tetraphenol ethane.

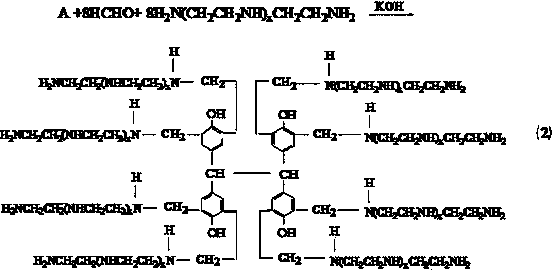

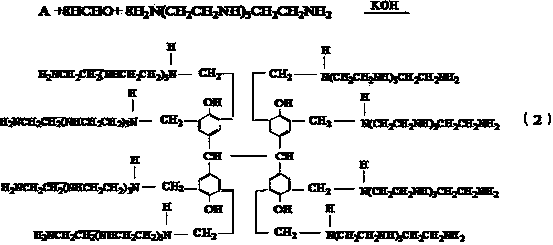

[0019] (2) Put 300 kg of polyethylene polyamine into the reaction kettle, then add 80 kg of tetraphenol ethane, stir for 30 minutes, then add 1.5 kg of potassium hydroxide as a catalyst, and add 130 kg of formaldehyde dropwise between 30 and 50 °C. After dripping, heat-retain and react for 1 hour, then add 1 / 2 xylene of the total amount of materials, reflux at about 100°C for 3 hours, and extract the water produced by the reaction and the water in the raw materials.

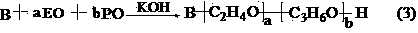

[0020] (3) Vacuum the product obtained in (2) for 15 minutes until the vacuum reaches -0.095MPa, add 12kg of potassium hy...

Embodiment 2

[0024] (1) Add 1000kg of phenol into the reaction equipment, add 1000kg of methanol as a solvent, then add 24kg of hydrochloric acid as a catalyst, add 100kg of glyoxal dropwise at 60-80°C, and control the dropping temperature and speed. After the reaction is completed, 8 kg of potassium hydroxide is added for neutralization, and the pH value is adjusted to 6-7 to obtain tetraphenol ethane.

[0025] (2) Put 300 kg of polyethylene polyamine into the reaction kettle, then add 80 kg of tetraphenol ethane, stir for 30 minutes, then add 1.5 kg of potassium hydroxide as a catalyst, and add 130 kg of formaldehyde dropwise between 30 and 50 °C. After dripping, heat-retain and react for 1 hour, then add 1 / 2 xylene of the total amount of materials, reflux at about 100°C for 3 hours, and extract the water produced by the reaction and the water in the raw materials.

[0026] (3) Vacuum the product obtained in (2) for 15 minutes until the vacuum reaches -0.095MPa, add 15kg of potassium hyd...

Embodiment 3

[0030] (1) Add 1500kg of phenol into the reaction equipment, add 800kg of methanol as a solvent, then add 30kg of hydrochloric acid as a catalyst, add 100kg of glyoxal dropwise at 60-80°C, and control the temperature and speed of dropping. After the reaction is completed, 10 kg of potassium hydroxide is added for neutralization, and the pH value is adjusted to 6-7 to obtain tetraphenol ethane.

[0031] (2) Put 300 kg of polyethylene polyamine into the reaction kettle, then add 80 kg of tetraphenol ethane, stir for 30 minutes, then add 1.5 kg of potassium hydroxide as a catalyst, and add 130 kg of formaldehyde dropwise between 30 and 50 °C. After dripping, heat-retain and react for 1 hour, then add 1 / 2 xylene of the total amount of materials, reflux at about 100°C for 3 hours, and extract the water produced by the reaction and the water in the raw materials.

[0032] (3) Vacuum the product obtained in (2) for 15 minutes until the vacuum reaches -0.095MPa, add 15kg of potassium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com