Micro-emulsified diesel oil and preparation method thereof

A micro-emulsion, diesel technology, applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of inability to play a good role in boosting, strong seasonality, and inability to adjust state, and achieve good catalytic synthesis effect. Solubility stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

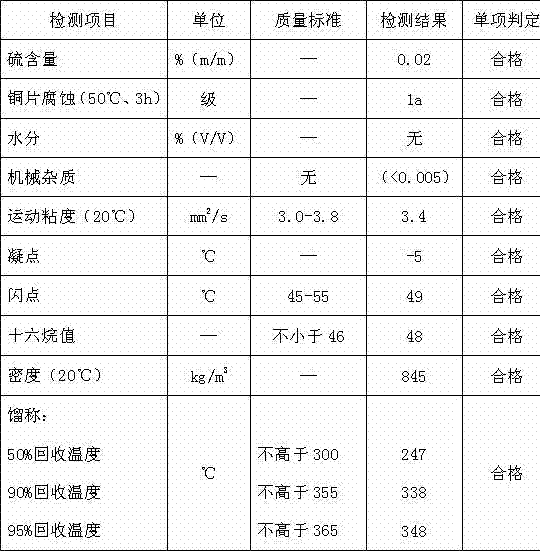

Embodiment 1

[0018] A micro-emulsion diesel oil is composed of the following components according to the mass fraction ratio: 70% diesel oil, 15% water, 3% cetane number enhancer and 12% emulsifier.

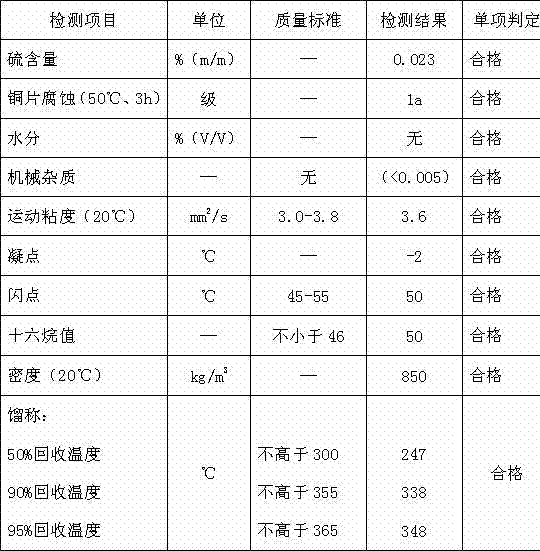

Embodiment 2

[0020] A micro-emulsion diesel oil is composed of the following components according to the mass fraction ratio: 65% diesel oil, 18% water, 5% cetane number enhancer and 10% emulsifier.

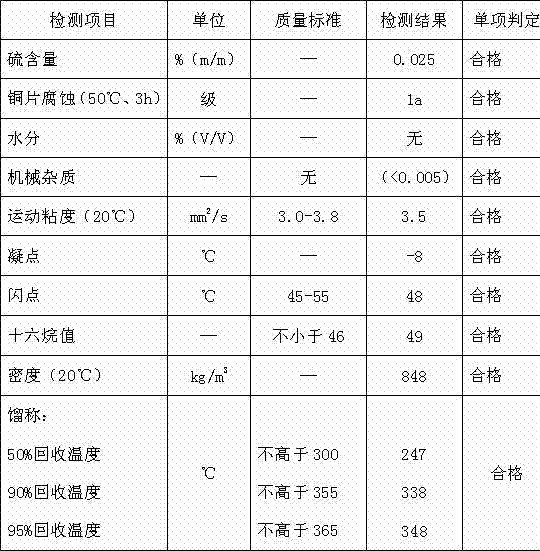

Embodiment 3

[0022] A micro-emulsion diesel oil is composed of the following components according to the mass fraction ratio: 75% diesel oil, 15% water, 4% cetane number improver and 6% emulsifier.

[0023] In above-mentioned each embodiment, emulsifying agent is by 27~32% naphthenic acid, 28~32% animal and vegetable oleic acid, 6~10% Pingpingjia, 2~4% sodium hydroxide, 3~5% polyethylene polyamine, 5 ~7% cyclohexylamine, 8~12% isoamyl alcohol, 4~6% secondary octanol and 4~6% potassium hydroxide; the cetane number enhancer is composed of 8~10% solvent oil, 6~8% sulfonic acid Magnesium acid, 14-16% tributyl phosphate, 8-12% isopropanol, 7-8% ethylene vinyl acetate, 8-12% isobutyl ester, 5-6% ferrocene, 4-5% cyclic Cobalt alkanoate, 4-5% naphthenate, 12-16% n-pentyl nitrate and 8-12% isooctyl nitrate. Among them, the emulsifier is preferably composed of 30% naphthenic acid, 30% animal and vegetable oleic acid, 7% pininga, 3% sodium hydroxide, 4% polyethylene polyamine, 6% cyclohexylamine, 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com