Polyethylene glycol chitosan self-assembled nanoparticles and preparation method thereof

A technology of self-assembled nanoparticles and polyethylene glycol, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problems of harsh preparation conditions and affecting the release of macromolecular substances, and achieve good biocompatibility, The effect of uniform size and stable water dispersion system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

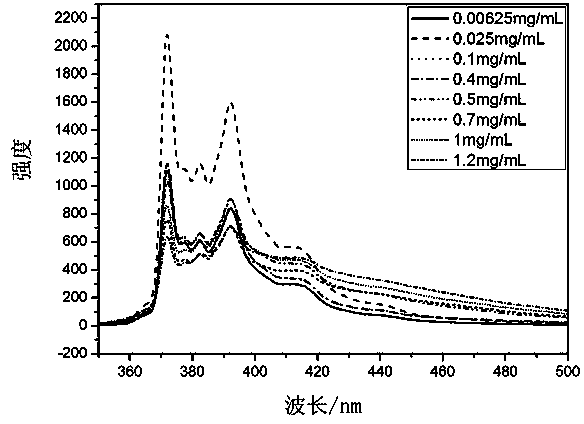

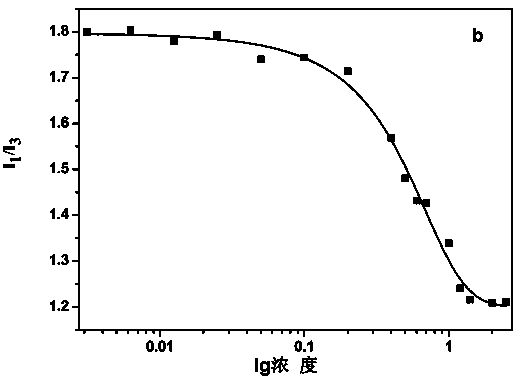

[0027] One, embodiment 1: prepare the polyethylene glycol chitosan self-assembled nanoparticle of PEG:CS=5:1:

[0028] 1. Synthesis of mPEG-COOH:

[0029] Weigh 5g of mPEG into a round-bottomed flask, dissolve with 25ml of dry pyridine, add 0.3g of succinic anhydride, react at 60°C for 2 hours, and remove most of the pyridine with a rotary evaporator at 45°C under reduced pressure. The obtained solid was dissolved in 30ml of toluene, stirred continuously on a magnetic heating stirrer, and 40ml of n-hexane precipitant was slowly added until the product was precipitated. The crude product was dialyzed with a dialysis bag for four days, and then the dialyzed material was freeze-dried to obtain the product, and mPEG-COOH with a molecular weight of 2000 could be obtained.

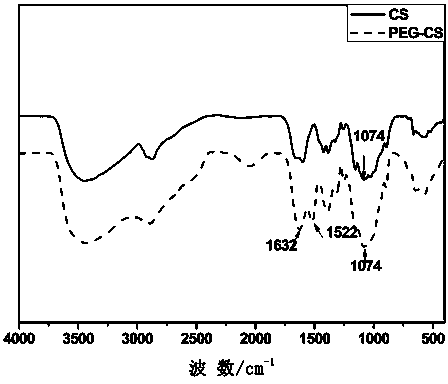

[0030] 2. Preparation of PEGylated Chitosan PEG-CS (PEG:CS=5:1):

[0031] Weigh 1 g of CS (500KDa) and dissolve it in 6 ml of acetic acid (2%, w / v), dilute it with 20 ml of TEMED·HCL with a pH of 4.7, add it t...

Embodiment 2

[0043] Two, embodiment 2: prepare the polyethylene glycol chitosan self-assembled nanoparticle of mPEG:CS=1:10:

[0044] 1. Synthesis of mPEG-COOH:

[0045] Weigh 5g of mPEG into a round-bottomed flask, dissolve with 25ml of dry pyridine, add 0.3g of succinic anhydride, react at 60°C for 2 hours, and remove most of the pyridine with a rotary evaporator at 45°C under reduced pressure. The obtained solid was dissolved in 30ml of toluene, stirred continuously on a magnetic heating stirrer, and 40ml of n-hexane precipitant was slowly added until the product was precipitated. The crude product was dialyzed with a dialysis bag for four days, and then the dialyzed material was freeze-dried to obtain the product, and mPEG-COOH with a molecular weight of 2000 could be obtained.

[0046] 2. Preparation of PEGylated chitosan PEG-CS (PEG:CS=1:10):

[0047] Weigh 1g CS (500KDa) and dissolve it in 6 ml acetic acid (2%, w / v), dilute it with 20 ml TEMED·HCL (pH 4.7), add it into a three-neck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com