125 DEG C irradiation crosslinked EPCV photovoltaic halogen-free flame-retardant sheath material and preparation method thereof

A flame retardant sheath and irradiation technology, applied in the direction of plastic/resin/wax insulators, rubber insulators, organic insulators, etc., can solve the inconvenience of installation, the inability to achieve low-smoke and halogen-free VW-1 flame retardant level, high hardness, etc. problems, achieve excellent flame retardancy and oil resistance, excellent mechanical properties and weather resistance, and low smoke emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

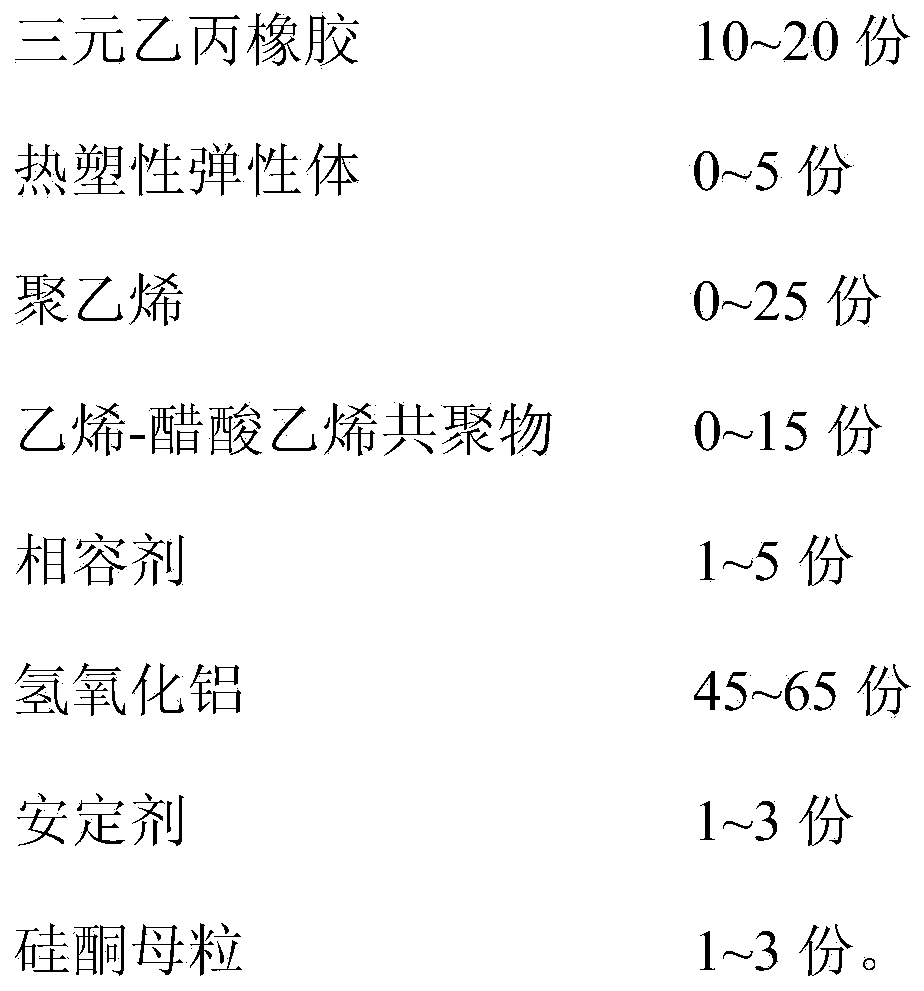

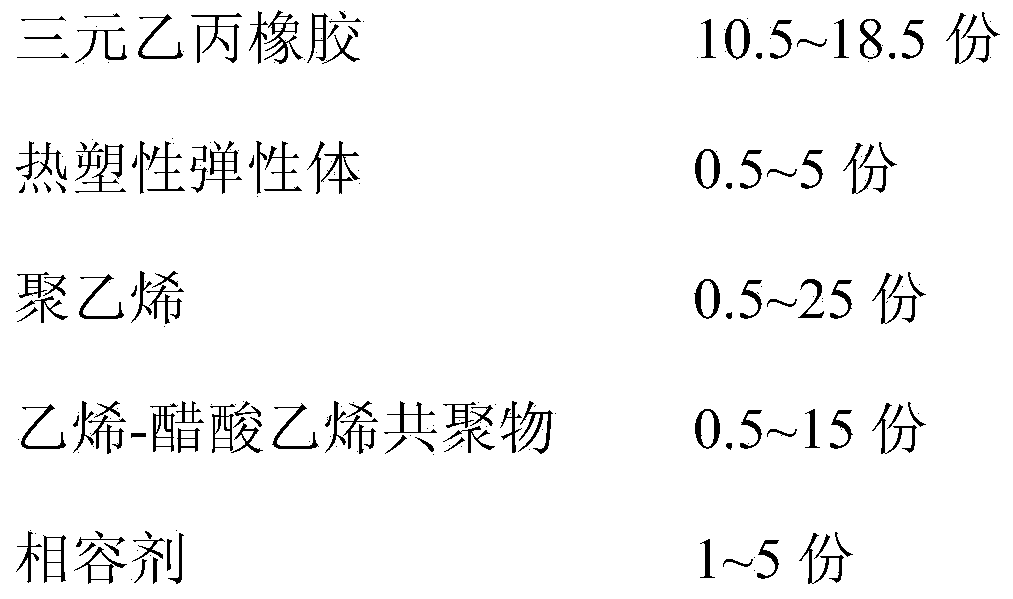

Method used

Image

Examples

Embodiment 1

[0068] A low-smoke halogen-free sheathed cable material for 125°C irradiation cross-linked EPCV photovoltaics, which is mainly made of the following raw materials in parts by weight: EPDM: 15 parts; thermoplastic elastomer (TPE): 1 part; polyethylene: 5 parts; ethylene-vinyl acetate copolymer: 10 parts; compatibilizer: 2 parts; aluminum hydroxide 63 parts; stabilizer: 2 parts; silicone masterbatch: 2 parts.

[0069] The ethylene-propylene segment molar ratio of the ethylene-propylene-diene rubber (EPDM) is 60:40, the third monomer is ethylidenebornene, and the mass percentage of the third monomer to the total mass of the three monomers is 3%, The number average molecular weight is 150,000, the Mooney viscosity at 100°C is 50 Pa·s, and the Shore A hardness is 40.

[0070] The thermoplastic elastomer (TPE) is an ethylene-propylene copolymer with a number average molecular weight of 150,000, a Mooney viscosity of 50 Pa·s at 100°C, a Shore A hardness of 60, and a melt index of 1 a...

Embodiment 2

[0086] A low-smoke halogen-free sheathed cable material for 125°C irradiation cross-linked EPCV photovoltaics, mainly made of the following raw materials in parts by weight: EPDM: 12 parts; thermoplastic elastomer (TPE): 2 parts; polyethylene: 10 parts; ethylene-vinyl acetate copolymer: 10 parts; compatibilizer: 2 parts; aluminum hydroxide 60 parts; stabilizer: 2 parts; silicone masterbatch: 2 parts.

[0087] The ethylene-propylene segment molar ratio of the ethylene-propylene-diene rubber (EPDM) is 60:40, the third monomer is ethylidenebornene, and the mass percentage of the third monomer to the total mass of the three monomers is 3%, The number average molecular weight is 150,000, the Mooney viscosity at 100°C is 50 Pa·s, and the Shore A hardness is 40.

[0088] The thermoplastic elastomer (TPE) is an ethylene-propylene copolymer with a number average molecular weight of 150,000, a Mooney viscosity of 50 Pa·s at 100°C, a Shore A hardness of 60, and a melt index of 1 at 190°C...

Embodiment 3

[0104] A low-smoke halogen-free sheathed cable material for 125°C irradiation cross-linked EPCV photovoltaics, which is mainly made of the following raw materials in parts by weight: EPDM: 18 parts; thermoplastic elastomer (TPE): 2 parts; polyethylene: 5 parts; ethylene-vinyl acetate copolymer: 12 parts; compatibilizer: 2 parts; aluminum hydroxide 59 parts; stabilizer: 2 parts; silicone masterbatch: 2 parts.

[0105]The ethylene-propylene segment molar ratio of EPDM is 60:40, the third monomer is ethylidenebornene, and the mass percentage of the third monomer to the total mass of the three monomers is 3%. , the number average molecular weight is 150,000, the Mooney viscosity at 100°C is 50Pa·s, and the Shore A hardness is 40.

[0106] The thermoplastic elastomer (TPE) is an ethylene-propylene copolymer with a number average molecular weight of 150,000, a Mooney viscosity of 50 Pa·s at 100°C, a Shore A hardness of 60, and a melt index of 1-1 at 190°C and 2.16kg. 5g / 10min.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com