Halogen-free fire-resistant engineering plastics using waste PET bottle chips as raw material and preparation method thereof

A technology of engineering plastics and bottle flakes, which is applied in the field of halogen-free flame-retardant engineering plastics and its preparation, can solve the problems of difficult engineering plastics recycling, material loss of mechanical properties, low mechanical strength, etc., and achieves no need for mold temperature molding processing and convenient preparation , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

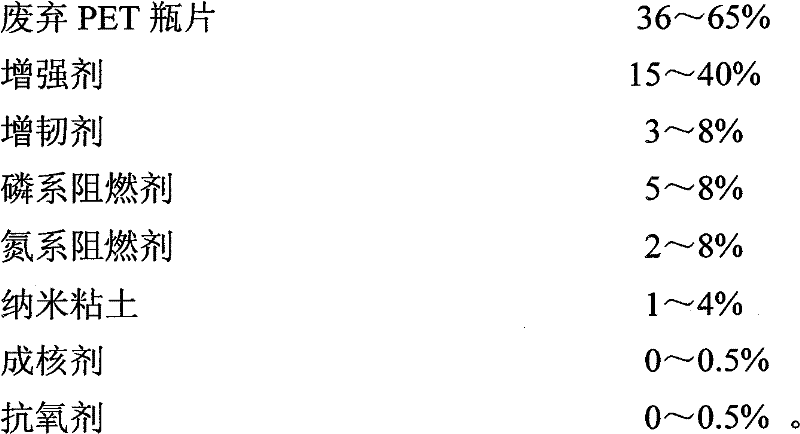

Method used

Image

Examples

Embodiment 1

[0059] (1) The waste PET bottle flakes were air-dried at 115°C for 4 hours;

[0060] (2) 48g of dried discarded PET bottle flakes (intrinsic viscosity is 0.5dl / g), 5g of toughening agent maleic anhydride grafted polyolefin elastomer, phosphorus-based flame retardant resorcinol polycondensed aryl phosphate 8g, nitrogen flame retardant melamine 6g, nanoclay (particle diameter is 100nm, selects Nanocor company I.28E) 2.5g, nucleating agent sodium benzoate 0.3g and antioxidant β-(4-hydroxyl-3,5- 0.2 g of n-octadecyl di-tert-butylphenyl)propionate was sequentially added into the mixer, and stirred and mixed for 3 minutes at a speed of 400 rpm to obtain a mixture;

[0061] (3) Add the mixture obtained in step (2) into a twin-screw extruder, and then pass 30 g of alkali-free long glass fibers treated with a reinforcing agent siloxane coupling agent through a glass fiber dryer (drying temperature 160 ° C, drying cylinder length 1.5m) after drying, it is introduced into the extruder f...

Embodiment 2

[0080] (1) The waste PET bottle flakes were air-dried at 115°C for 4 hours;

[0081] (2) 36g of dried discarded PET bottle flakes (intrinsic viscosity is 0.4dl / g), 8g of acrylate-glycidyl-ethylene copolymer with epoxy functional group as toughening agent, phosphorus-based flame retardant triphenyl phosphate Ester 8g, nitrogen flame retardant ammonium polyphosphate 6g, nanoclay (particle diameter is 50nm, selects Nanocor company I.28E) 1.5g, nucleating agent talcum powder 0.3g and antioxidant tetrakis (3,5-di 0.2 g of tert-butyl-4-4-hydroxyphenyl) was successively added into a mixer, and stirred and mixed for 3 minutes at a speed of 400 rpm to obtain a mixture;

[0082] (3) Add the mixture obtained in step (2) into a twin-screw extruder, and then pass 40 g of alkali-free long glass fibers treated with a reinforcing agent siloxane coupling agent through a glass fiber dryer (drying temperature 180 ° C, drying cylinder length 0.5m) after drying, it is introduced into the extruder...

Embodiment 3

[0101] (1) Dry the discarded PET bottle flakes at 100° C. for 6 hours;

[0102] (2) 62g of dried waste PET bottle flakes (intrinsic viscosity is 0.6dl / g), 3g of acrylate-glycidyl-ethylene copolymer with epoxy functional group as toughening agent, 3g of phosphorus-based flame retardant tricresyl phosphate Ester 5g, nitrogen flame retardant melamine cyanurate 8g, nanoclay (particle diameter is 80nm, select Nanocor company I.28E) 1.5g, nucleating agent zinc oxide 0.3g and antioxidant three (2,4-di 0.2 g of tert-butylphenyl) phosphite was sequentially added to the mixer, and stirred and mixed for 3 minutes at a speed of 400 rpm to obtain a mixture;

[0103] (3) Add the mixture obtained in step (2) into the twin-screw extruder, and then introduce 20 g of the short glass fiber of the reinforcing agent after drying (drying at 150°C for 2 hours) into the extruder from the glass fiber port, and melt extrude After granulation, the extruded material is cooled, air-dried, pelletized, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com