Thermosetting resin composition, prepreg and laminated board

A technology of resin composition and prepreg, which is applied in the field of thermosetting resin composition and laminates, can solve the problems of high brittleness of resin matrix, limited application of high-performance printed circuit board substrate, low water absorption, etc., and achieves low water absorption, Low dielectric constant and loss, effect of low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] According to the method in the synthesis example, react at 140°C for 30 minutes to prepare 70 g of prepolymer of 4,4'-diphenylmethane bismaleimide resin:diallyl bisphenol A=100:60, add appropriate amount of acetone dissolve. After the modified double horse resin is completely dissolved, add 10g biphenyl type multifunctional epoxy resin (NC-3000, Nippon Kayaku), 20g bisphenol A type cyanate resin (BA-3000S, Lonza), 10g phosphorus-containing Phenolic resin (XZ92741, Dow Chemical), 0.02g zinc octoate, 100g spherical silica (average particle size 0.7um, SFP-30M, DENKA) and an appropriate amount of butanone solvent, stirred and mixed evenly to obtain a gel with a solid content of 60%. liquid.

[0052] The glue is dipped and coated on E glass fiber cloth (2116, the unit weight is 104g / m 2 ) and baked in an oven at 160°C for 5 minutes to obtain a prepreg with a resin content of 50%.

[0053] The prepared prepreg with a resin content of 50% was placed with a metal copper foi...

Embodiment 2

[0056] According to the method in the synthesis example, react at 140°C for 35 minutes to prepare 30 g of prepolymer of 4,4'-diphenylmethane bismaleimide resin:diallyl bisphenol A=100:70, add appropriate amount of acetone dissolve. After the modified double horse resin is completely dissolved, add 20g biphenyl type multifunctional epoxy resin (NC-3000, Nippon Kayaku), 50g bisphenol A type cyanate resin (BA-3000S, Lonza), 10g phosphorus-containing Phenolic resin (XZ92741, Dow Chemical), 0.05g stannous octoate, 100g spherical silica (average particle size 0.7um, SFP-30M, DENKA) and an appropriate amount of butanone solvent, stirred and mixed evenly to obtain 60% solid content Glue.

[0057] The preparation methods of the prepreg and the copper-clad laminate are the same as in the first embodiment.

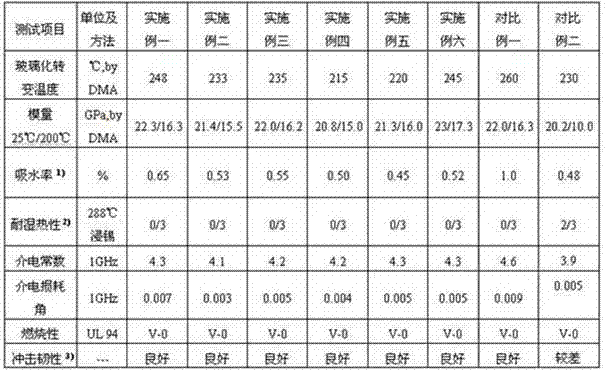

[0058] The properties of the obtained copper-clad laminates are shown in Table 1.

Embodiment 3

[0060] According to the method in the synthesis example, react at 130°C for 45 minutes to prepare 50 g of prepolymer of 4,4'-diphenylisopropylbismaleimide resin:diallyl diphenyl ether=100:75, add Appropriate amount of acetone dissolved. After the modified double horse resin is completely dissolved, add 15g of dicyclopentadiene type epoxy resin (XD-1000, Nippon Kayaku), 35g of dicyclopentadiene type cyanate resin (CY-3, Jiangdu Malt Chemical Co., Ltd. ), 10g phosphazene (SPB-100, Japan Otsuka Chemical Co., Ltd.), 0.05g zinc octanoate, 70g spherical silica (average particle size 0.7um, SFP-30M, DENKA), 30g boehmite (BS100, Kawai lime ) and an appropriate amount of butanone solvent, stir and mix evenly to obtain a glue with a solid content of 60%.

[0061] The preparation methods of the prepreg and the copper-clad laminate are the same as in the first embodiment.

[0062] The properties of the obtained copper-clad laminates are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com