Temperature change resistant PVC wood grain film printing yellow ink

A technology of wood grain film and temperature resistance, which is applied in ink, household utensils, applications, etc., can solve the problems of unsatisfactory color concentration, poor pigment encapsulation, poor color development of ink, etc., to solve the problem of large color decay at high temperature and improve Effect of heat resistance and improvement of wetting and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

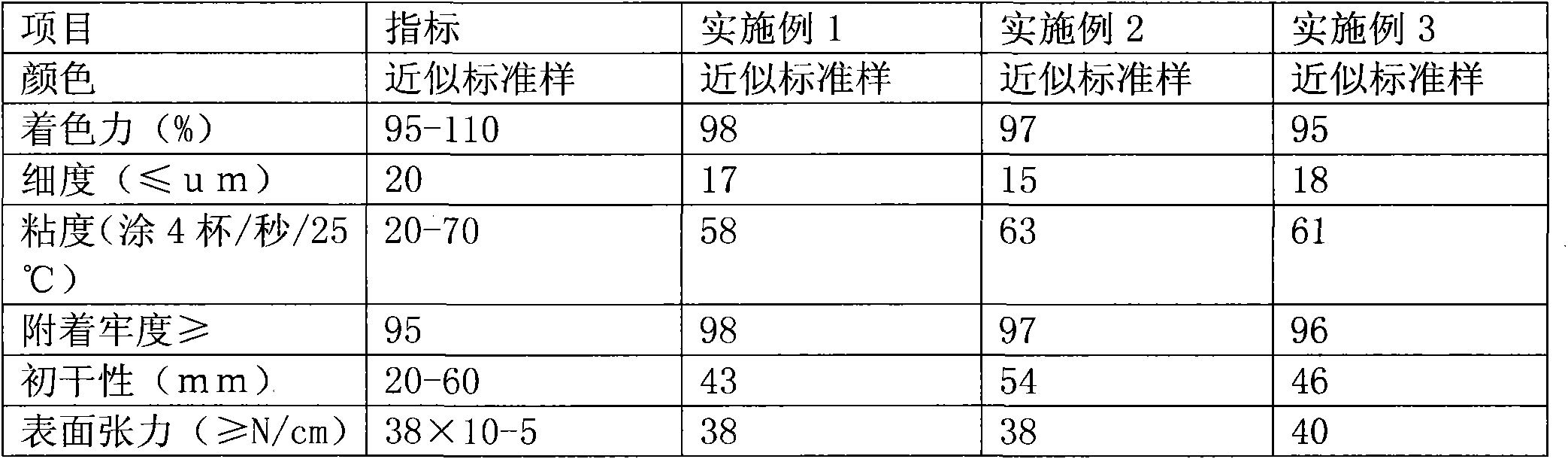

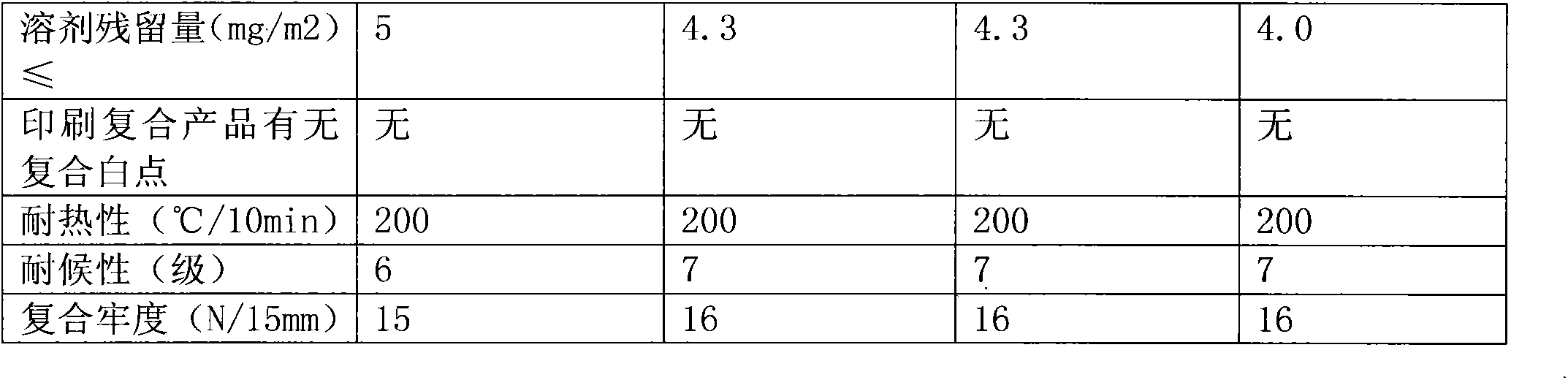

Embodiment 1

[0047] One, prepare 20% carboxyl-modified ternary compound vinyl acetate resin liquid:

[0048] Adopting the ethyl acetate that is 15% by weight, the n-propyl acetate that is 15% by weight and the methyl ethyl ketone that is 50% by weight as solvent, the modified ternary compound chloroacetic ester that dissolves 20% by weight, obtains 20 % Carboxyl-modified ternary compound vinyl resin solution.

[0049] Two, prepare temperature-resistant variable PVC wood grain film printing yellow ink, its raw material formula and weight percentage thereof are:

[0050] 30% Modified Polyurethane-Acrylic Emulsion: 35%

[0051] 20% carboxy-modified ternary compound vinyl resin solution: 25%

[0052] Benzidine Yellow: 10%

[0053] Filler: 4%

[0054] Functional resin: 2%

[0055] Polyethylene wax: 1%

[0056] Special additives: 3%

[0057] Ethyl acetate: 10%

[0058] Butanone: 10%

[0059] 3. The preparation method of yellow ink for temperature-resistant PVC wood grain film printing i...

Embodiment 2

[0066] One, prepare 20% carboxyl-modified ternary compound vinyl acetate resin liquid:

[0067] Adopting the ethyl acetate that is 15% by weight, the n-propyl acetate that is 15% by weight and the methyl ethyl ketone that is 50% by weight are as solvent, and the modified ternary compound chloroacetic ester that dissolves 20% by weight is obtained 20 % Carboxyl-modified ternary compound vinyl resin solution.

[0068] Two, prepare temperature-resistant variable PVC wood grain film printing yellow ink, its raw material formula and weight percentage thereof are:

[0069] 30% Modified Polyurethane-Acrylic Emulsion: 26%

[0070] 20% carboxyl-modified ternary compound vinyl resin solution: 28%

[0071] Benzidine Yellow: 14%

[0072] Filler: 1%

[0073] Functional resin: 4%

[0074] Polyethylene wax: 2%

[0075] Special additives: 4%

[0076] Ethyl acetate: 10%

[0077] Butanone: 11%

[0078] 3. The preparation method of the yellow ink printed on the temperature-resistant PVC...

Embodiment 3

[0080] One, prepare 20% carboxyl-modified ternary compound vinyl acetate resin liquid:

[0081] Adopting the ethyl acetate that is 15% by weight, the n-propyl acetate that is 16% by weight and the methyl ethyl ketone that is 52% by weight as solvent, the modified ternary compound chloroacetic ester that dissolves 17% by weight, obtains 20 % Carboxyl-modified ternary compound vinyl resin solution.

[0082] Two, prepare temperature-resistant variable PVC wood grain film printing yellow ink, its raw material formula and weight percentage thereof are:

[0083] 30% Modified Polyurethane-Acrylic Emulsion: 25%

[0084] 20% carboxyl-modified ternary compound vinyl resin solution: 33%

[0085] Benzidine Yellow: 12%

[0086] Filler: 2%

[0087] Functional resin: 3%

[0088] Polyethylene wax: 1%

[0089] Special additives: 2%

[0090] Ethyl acetate: 12%

[0091] Butanone: 10%

[0092] 3. The preparation method of the yellow ink printed on the temperature-resistant PVC wood grain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com