Patents

Literature

40 results about "Benzidine yellow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

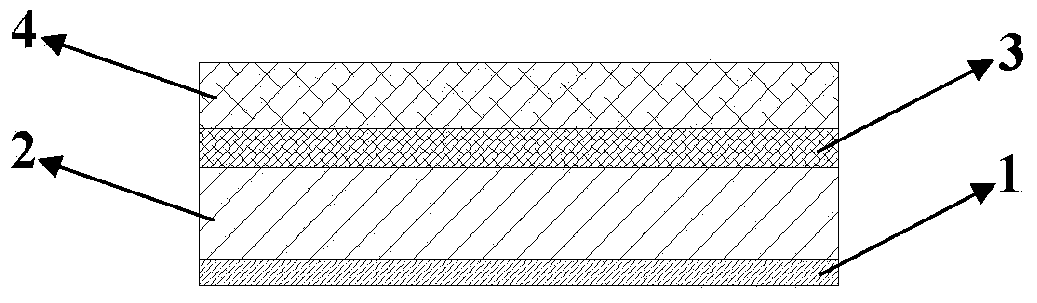

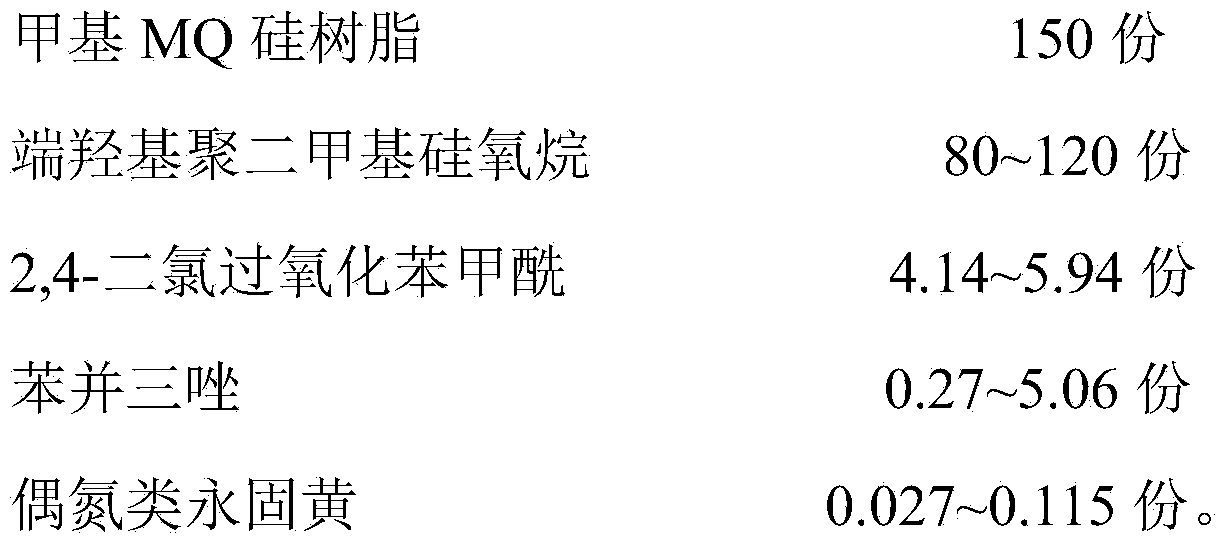

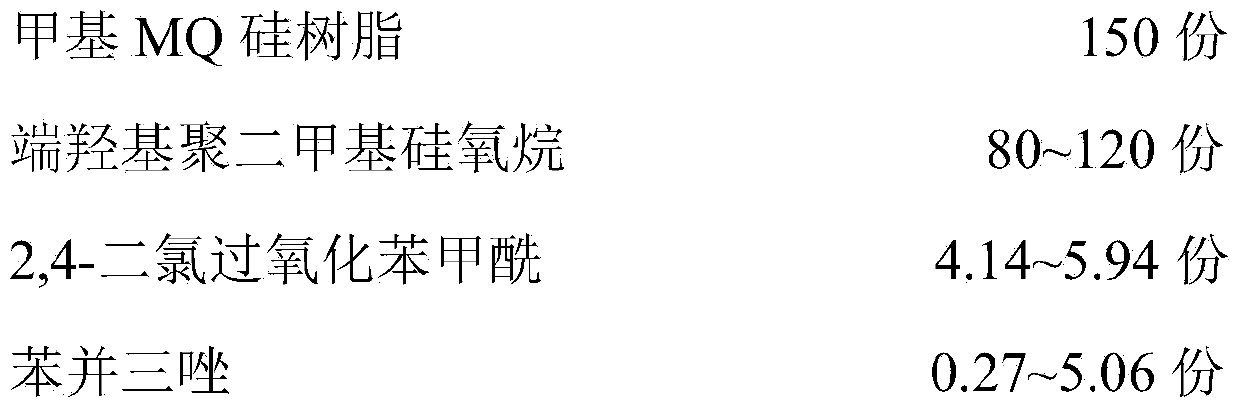

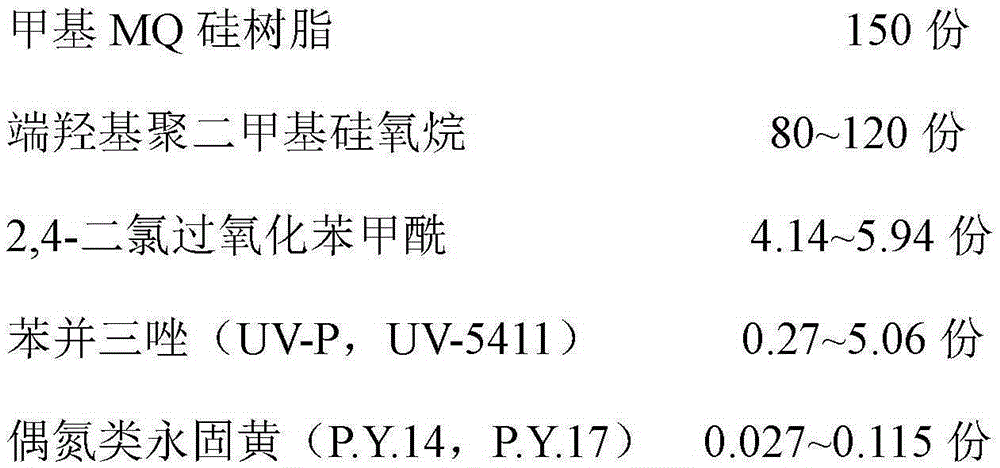

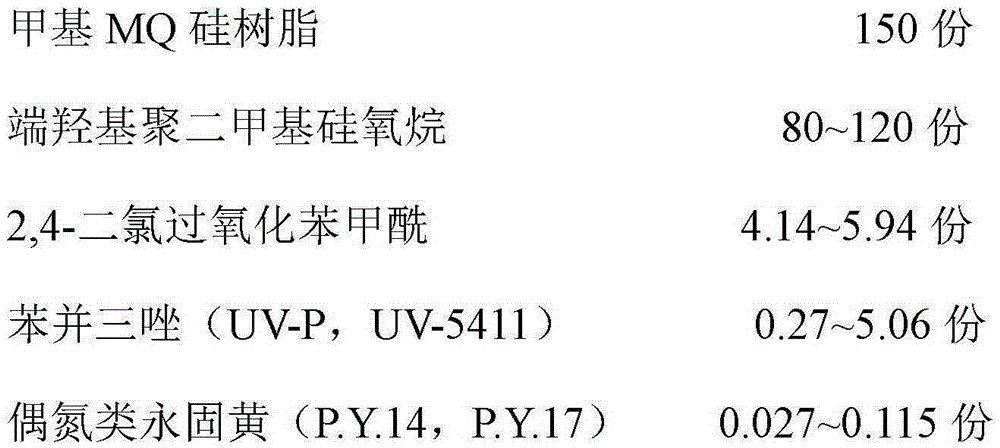

Blue-light-prevention screen protective membrane and preparation method thereof

ActiveCN103991255AAvoid damageUniform thicknessSynthetic resin layered productsLaminationDimethyl siloxaneBlocking layer

The invention discloses a blue-light-prevention screen protective membrane and a preparation method of the blue-light-prevention screen protective membrane, wherein the blue-light-prevention screen protective membrane is composed of a scrape-resistant coating, a film substrate layer, a blue light blocking layer and a release membrane layer; one surface of film substrate layer is coated by the scrape-resistant coating; the other surface of the film substrate layer is coated by the blue light blocking layer; the other surface of the blue light blocking layer is coated by the release membrane layer. The blue light blocking layer consists of the following components in parts by mass: 150 parts of methyl MQ silicon resin, 80-120 parts of terminated polydimethylsiloxane, 4.14-5.94 parts of 2, 4-dichlorobenzoyl peroxide, 0.27-5.06 parts of benzotriazole and 0.027-0.115 part of azo-type benzidine yellow. The blue-light-prevention screen protective membrane provided by the invention can resist blue light with the wavelength of 380-480nm, reduces the injury of blue light to retina, moreover has favorable visible light transmittance, and can be effectively compatible with visible light transmittance and blue light blocking rate; the coating is uniform and controllable in thickness; the preparation process is simple and low in cost.

Owner:TAIHU JINZHANG TECH CO LTD

Preparation method of fertilizer colorant and application method thereof

The invention relates to a preparation method of a fertilizer colorant and an application method thereof. The preparation method comprises the following steps of: respectively dissolving water-soluble dyes such as bright red, rose red, acid blue, brilliant blue, golden yellow or lemon yellow into water; respectively adding 1-3% dispersing agent; stirring and respectively preparing into red inner colorant, blue inner colorant and yellow inner colorant for later use; respectively dissolving oil-soluble dyes such as lithol red, toluidine red, phthalocyanine blue, transparent blue, benzidine yellow or fluorescence yellow into base oil dissolvent; respectively adding the 1-3% dispersing agent; stirring and respectively preparing into red outer colorant, blue outer colorant and yellow outer colorant; directly stirring and blending the inner colorants and fertilizer raw materials; and spraying the outer colorants, so that the fertilizer is evenly colored. The preparation method can prepare the colored fertilizer which can not discolor under the functions of strong acid, strong base, strong reductant, strong oxygenant and microbe, and has the characteristics of small use amount of the colorant, stable coloration, low cost, pure color, good appearance, wide adaptability, high safety, good performance and the like.

Owner:广东新绿源化工有限公司

Cable lettering ink

The invention belongs to the field of printing technology, and particularly relates to cable lettering ink which is characterized by comprising the following raw materials in parts by weight: 4-6 parts of polyvinyl chloride resin, 5-9 parts of acrylate polymer, 30-40 parts of methyl ethyl ketone, 13-18 parts of toluene, 5-10 parts of isobutyl methacrylate, 10-18 parts of tetrahydrofuran, 3-5 parts of benzidine yellow or titanium dioxide or lithopone with fineness of 400-800 meshes, 6-10 parts of 2-lead ethylcaproate, 0.3-0.5 part of methylparaben or propylparaben or butylparaben and 3-4.5 parts of butyl acetate. The invention also discloses a preparation method of the lettering ink. The cable lettering ink and the preparation method provided by the invention have the main beneficial effects that the preparation method is simple and easy to master, and the qualified rate of the finished product is high; the lettering ink has the advantages of high adhesion, high drying speed, bright luster and longer shelf life.

Owner:STATE GRID CORP OF CHINA +1

Enamel coating for pan and preparation method thereof

ActiveCN110255909AImprove high temperature resistanceImprove impact performanceCooking-vessel materialsTetramethyl-p-phenylenediamineTemperature resistance

The invention discloses an enamel coating for a pan, the enamel coating comprises the following raw materials in parts by weight: 100-150 parts of enamel frit, 4-10 parts of titanium dioxide, 0.8-1.2 parts of benzidine yellow, 1.5-3.5 parts of cage-type polysilsesquioxane, 1-3 parts of an inorganic acid, 0.3-0.8 parts of potassium titanate, 10-30 parts of N, N, N', N'-tetramethyl p-phenylenediamine dihydrochloride, 5-15 parts of an ionic liquid and 30-50 parts of deionized water. The enamel coating for the pot has good high temperature resistance and corrosion resistance, can effectively slow down the phenomenon that the enamel coating for the pan falls off under the action of high temperature and acid and alkali solutions, and the sintering condition and sintering quality of the enamel coating are simultaneously improved, so that the enamel coating has more excellent decorative effect and comprehensive physical properties. The invention also discloses a preparation method of the enamel coating for the pan.

Owner:宁波市金象厨具有限公司

A kind of writing paper for preventing myopia

InactiveCN104343040BSoft colorColor softeningNatural cellulose pulp/paperPulp bleachingSlurryChrysophenine

The invention discloses a light-yellow writing paper capable of preventing myopia. The preparation method of the writing paper comprises the following steps: mixing hardwood slurry and softwood slurry according to a weight ratio of 1:0.5-1.3, bleaching the mixed slurry, dispersing the slurry, grinding the slurry, proportioning the slurry to obtain paper slurry, and finally moulding the paper slurry to obtain paper through a conventional method. During the slurry proportioning process, the following additives are added in percentage by the total weight of paper slurry: 0.001 to 0.002% of alkaline light yellow, 0.001 to 0.006% of alkaline orange, 0 to 0.001% of benzidine yellow, 0.001 to 0.002% of chrysophenine G, and 0.01% of titanium dioxide. The prepared writing paper has the following advantages: (1) the color of the paper surface is light yellow, the luster and color are soft, and the myopia can be effectively prevented; (2) the writing on the paper is fluent, the phenomenon of ink dispersion and fading is avoided, and the color is stable even after a long time preservation; (3) the growth of harmful bacteria on the paper is inhibited, and thus the health of users is guaranteed.

Owner:川印文化集团股份有限公司

Method for preparing rosin derivative for pigment industry

InactiveCN103450809AHigh tinting strengthImprove thermal stabilityNatural resin chemical modificationAlkylphenolReaction temperature

The invention discloses a method for preparing a rosin derivative for the pigment industry and relates to the technical field of deep processing of rosin. The method comprises the following steps of: adding alkylphenol disulfide which accounts for 0.1-1.0% of the total mass of rosin into the rosin and carrying out disproportionation reaction, wherein the reaction temperature is 260-280 DEG C and the reaction time is 2-6 hours; cooling down after the reaction is accomplished; adding tannic acid which accounts for 0.3-1.0% of the total mass of the rosin at 160-200 DEG C; stirring and reacting for 1-3 hours; and taking out the product which is the rosin derivative. Compared with the prior art, the rosin derivative can improve the tinting strength of the pigment, is high in transparency and is nature and environment-friendly. The rosin derivative is mainly applied to industries such as pigment synthesis and is particularly applicable to preparation of benzidine yellow pigment with high additive amount.

Owner:WUZHOU PINE CHEM

Preparation process of benzidine yellow

The invention discloses a preparation process of benzidine yellow, which is characterized by comprising the following steps of: adding 1150-1250L of water, 95-110 KG of acetoacetanilide and 2.5-3.5 KG of an assistant into a coupling barrel, mixing and beating the obtained mixture for 60-70 min, adding 180-200 KG of 56-100% sodium acetate and 15-30% filler into the coupling barrel, and adding ice blocks into the coupling barrel so as to cool the obtained object to 15-17 DEG C; adding 10-13 KG of a hydrochloric acid with the concentration of 30-33%, and adjusting the pH of the obtained mixture to be 6-7; adding 60-80 KG of 100% diazo fluid into the coupling barrel, controlling the temperature at 7-12 DEG C, and controlling the pH at 3.5-4.0; in the later period of adding the diazo liquid, carrying out detection by using a ring lubricating test method; and after the reaction is completed, stopping adding the diazo liquid, heating the liquid material to 90-120 DEG C by using steam, and carrying out heat preservation for 25-35 min. A pigment prepared according to the preparation process of the benzidine yellow is uniform in color strength and more stable in crystal form.

Owner:瑞安宝源化工有限公司

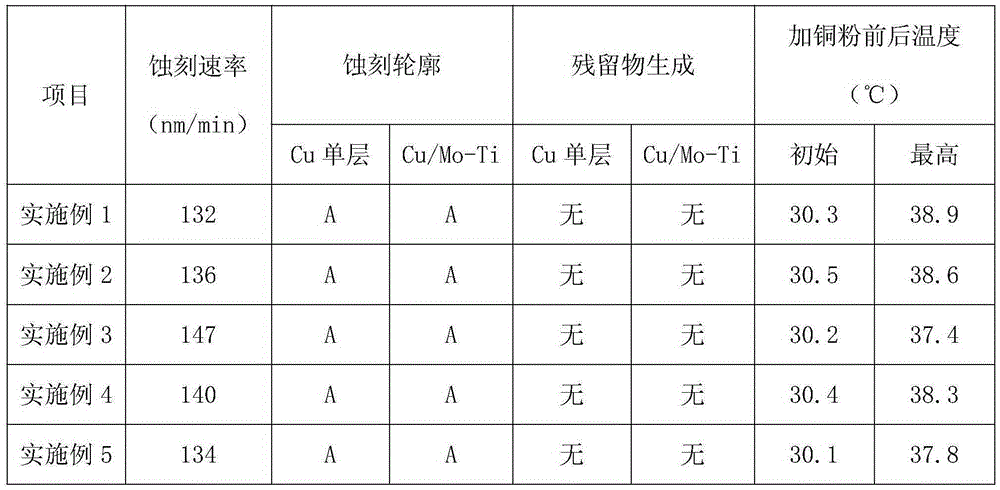

Metal etching agent used for etching copper-containing metal layer and preparation method for metal etching agent

InactiveCN105386056AIncrease etch rateImprove etching efficiencySemiconductor/solid-state device manufacturingDecompositionSodium fumarate

The invention discloses a metal etching agent used for etching a copper-containing metal layer and a preparation method for the metal etching agent. The metal etching agent comprises, by weight, 20-30 parts of hydrogen peroxide, 1-5 parts of acetic acid, 1-3 parts of nitrilotriacetic acid, 10-15 parts of sodium carboxymethyl cellulose, 15-20 parts of boric acid, 12-14 parts of sodium fumarate, 1-2 parts of sodium fluoride, 4-10 parts of ethylene glycol, 2-10 parts of benzidine yellow, 6-8 parts of barium stearate and 8-12 parts of azodiisobutyronitrile. The invention further provides the preparation method for the metal etching agent used for etching the copper-containing metal layer. The etching speed of the metal etching agent is above 132 nm / min, and is far higher than that of common etching liquid, so that the etching efficiency is improved. Under the condition of adding copper powder, the metal etching agent only has the highest temperature of 38.9 DEG C, and therefore the decomposition of the effective component hydrogen peroxide is restrained, and the stability is obviously improved.

Owner:NINGBO DONGSHENG INTEGRATED CIRCUIT ELEMENT

Preparation technique for diazo liquid of benzidine yellow G

The invention discloses a preparation technique for diazo liquid of benzidine yellow G. The preparation technique includes steps of: double chloride beating: 650-750 KG of water, 105-125 KG of 30-35% hydrochloric acid and 60-80 KG of double chloride are filled in a diazo barrel to be stirred and beat for at least 1h, and ice cubes are filled in the barrel to lead temperature of material liquid in the barrel to be cooled to be below 0 DEG C; diazotizing: 38.4-39 KG of 38-42% sodium nitrite is filled in the barrel and reacts fro 40-90 min at temperature below 5 DEG C, 0.9-1.5 KG of activated carbon is filled in the barrel to be stirred for 3-10 min, water is filled in the barrel to lead the total volume to reach 1050-1150 L, 0.3-0.7 KG of Turkey red oil is filled after all liquid in the barrel is diluted for 9-11 times and is stirred for at least 1 min, and the liquid is led to stand; suction filtration: diazo liquid is filtered through a cloth bag during suction filtration. The preparation technique can prevent double chloride from having homocoupling reactions, and the quantity of generated poisonous gases is small.

Owner:瑞安宝源化工有限公司

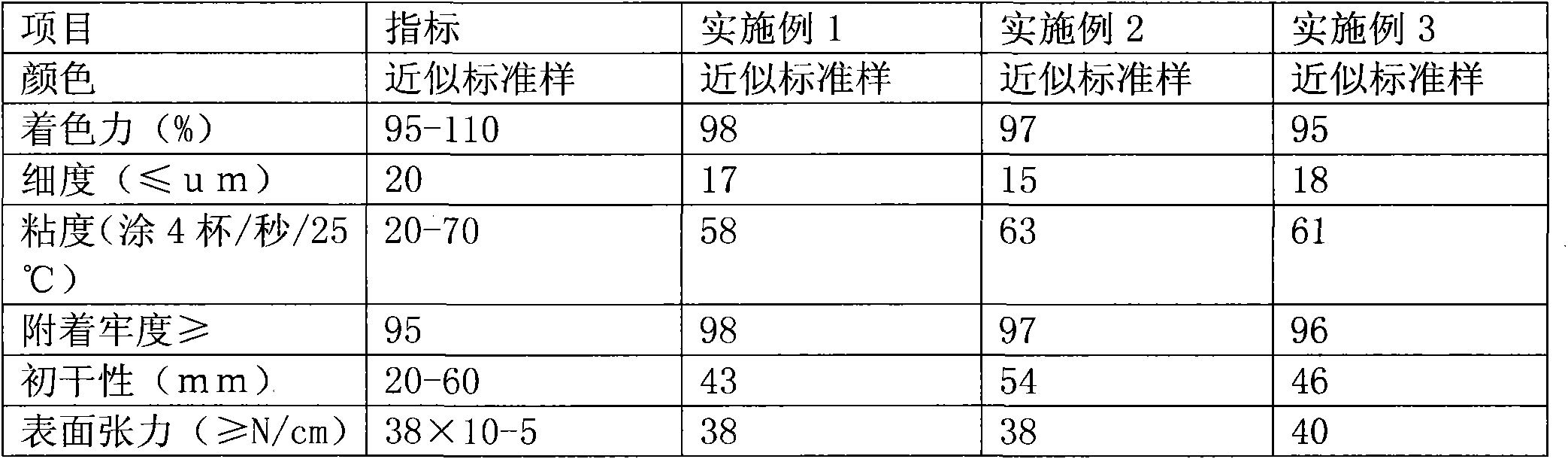

Silk screen ink for paper

InactiveCN103436077AFast dryingImprove adhesion fastnessInksPolymer scienceEthyl(hydroxyethyl)cellulose

The invention relates to silk screen ink for paper, which comprises the following components in parts by mass: 5-10 parts of benzidine yellow, 30-40 parts of light calcium carbonate, 15-30 parts of precipitated barium sulphate, 5-10 parts of methoxyl dipropanol, 2-6 parts of ethylhydroxyethylcellulose, 1-4 parts of butanone, 0.1-0.4 parts of cobalt naphthenate, 10-20 parts of pentalyn, 0.5-0.7 parts of manganese naphthenate, 1-5 parts of dioctyl phthalate and 1-2 parts of polyethylene wax. The silk screen ink for the paper is wear-resistant, high in drying speed, high in adhesion fastness, non-toxic, pollution-free, low in cost, heat-resistant, acid / alkali-resistant and solvent-oil-resistant, and does not adhere to dirt.

Owner:苏州凹凸彩印厂

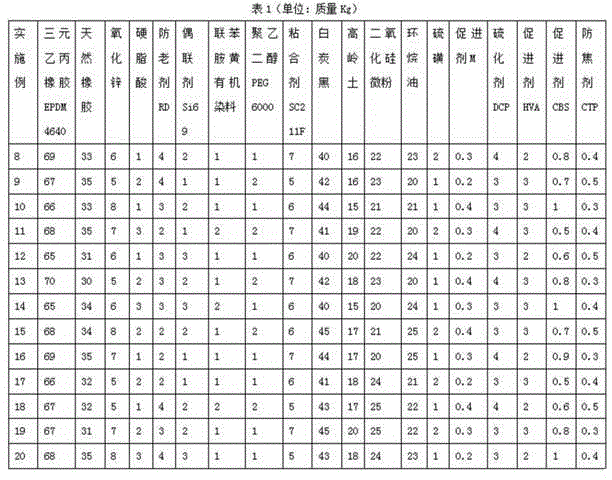

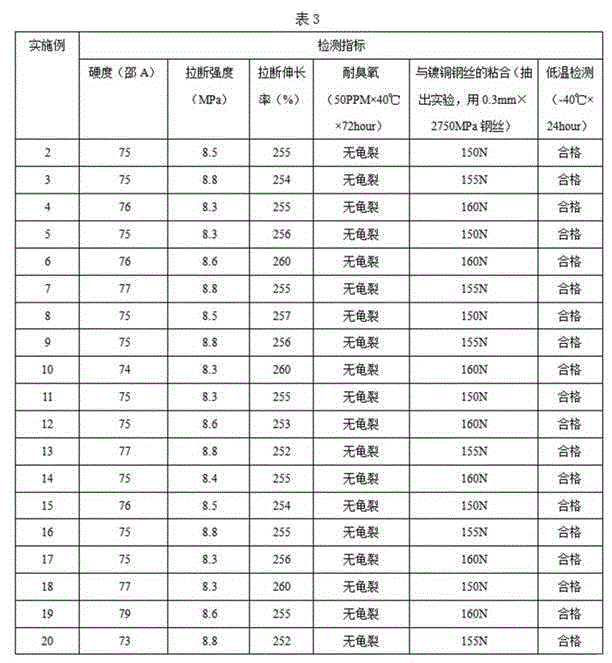

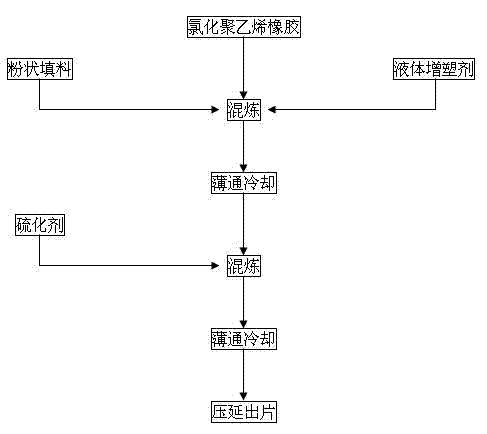

Yellow outer rubber for bus air conditioner rubber pipes and preparation method thereof

The invention provides yellow outer rubber for bus air conditioner rubber pipes and a preparation method thereof. The yellow outer rubber is prepared from the following raw materials by a compounding process and a mixing process of blended rubber of ethylene propylene terpolymer and natural rubber: ethylene propylene terpolymer EPDM4640, natural rubber, zinc oxide, stearic acid, antioxidant RD, coupling agent Si69, benzidine yellow organic pigment, polyethylene glycol PEG6000, adhesive SC211F and the like. The yellow outer rubber for bus air conditioner rubber pipe prepared from the material is excellent in physical properties and good in adhesiveness with coppered steel wires, and the physical properties, the weather resistance, the ageing resistance and the permeability resistance on R134a refrigerant of the yellow outer rubber are well perfected.

Owner:LUOHE LETONE RUBBER

Environmental-friendly low-smoke and low-halogen mining cable sheath rubber skin

ActiveCN102604244BMeet actual needsLow-smoke and low-halogen hasPlastic/resin/waxes insulatorsInsulated cablesMicrocrystalline waxEngineering

The invention discloses environmental-friendly low-smoke and low-halogen mining cable sheath rubber skin. The cable sheath rubber skin comprises the following material components in parts by weight: 100 parts of chlorinated polyethylene rubber, 10-15 parts of magnesium oxide, 3-5 parts of environmental-friendly stabilizer, 5-8 parts of microcrystalline wax, 15-25 parts of white carbon black, 15-25 parts of nanometer argil, 15-25 parts of aluminum hydroxide, 15-25 parts of environmental-friendly composite flame retardant, 3-5 parts of DCP (Dibasic Calcium Phosphate), 3-5 parts of PDM (metaphenylene bismaleimide), 1-2 part of RD (2,2,4-trimethyl-1,2-dihyaroquinoline polymer), 10-15 parts of IPPP (Isopropyl Phenyl Diphenyl Phosphate) and 3-5 parts of benzidine yellow or fast red salt. Due to the adoption of the cable sheath rubber skin, the flame retarding requirement of a mining cable can be met; and the cable sheath rubber skin has low smoke and low halogen, and is environmental-friendly.

Owner:上海沪安电缆(无锡)有限公司

Efficient fast drying ink

InactiveCN105086613AHigh bonding strengthImprove reaction efficiencyInksPolymer scienceDibutyl tin dilaurate

The invention discloses efficient fast drying ink. The efficient fast drying ink comprises a binder, a filler, a drying agent, a dispersing agent, an initiating agent, a pigment and a solvent, wherein the binder is polyurethane; the filler is talcum powder; the drying agent is dibutyltin dilaurate; the dispersing agent is ethylene bis stearamide; the initiating agent is dicyclohexyl peroxydicarbonate; the pigment is benzidine yellow; the solvent is isopropyl alcohol. The efficient fast drying ink comprising the binder, the filler, the drying agent, the dispersing agent, the initiating agent, the pigment and the solvent has the characteristics of being high in drying speed, low in cost, high in bonding strength and reaction efficiency and bright in color.

Owner:SUZHOU YONGJIN COLOR PRINTING PACKAGING

Temperature change resistant PVC wood grain film printing yellow ink

The invention provides a temperature change resistant PVC wood grain film printing yellow ink comprising the raw material formula by the weight percentage: 25-40% of a 30% modified polyurethane-acrylic acid emulsion, 25-40% of a 20% carboxyl modified ternary composite vinisol solution, 10-15% of benzidine yellow, 1-5% of a filling material, 1-6% of a functional resin, 1-3% of polyethylene wax, 1-5% of a dedicated auxiliary agent, 10-15% of ethyl acetate, and 10-15% of butanone. Aiming at the performance characteristic of the temperature change resistant PVC wood grain film printing yellow ink and the process requirement of adhesive-free high-temperature self-bonding compositing, the modified polyurethane-acrylic acid emulsion and the carboxyl modified ternary composite vinisol resin are added in the formula, so that adverse reactions of the yellow ink and an adhesive basal material during adhesive-free self-bonding of a print can be improved and avoided to the largest extent, the problems that the composite product has large color decay when meeting the high temperature and has low bonding fastness are solved, and the quality of the product is ensured.

Owner:HUANGSHAN SHINING INK TECH

Preparation method of benzidine yellow letter press ink

The invention relates to a preparation method of benzidine yellow letter press ink. The benzidine yellow letter press ink is characterized by comprising the following active ingredients in parts by weight: 52-60 parts of acrylic acid-modified rosin, 21-40 parts of tung oil, 2-3 parts of cobalt naphthenate, and 20-30 parts of benzidine yellow; the preparation method comprises the steps: mixing the acrylic acid-modified rosin, tung oil, cobalt naphthenate and benzidine yellow; heating at 90 DEG C, agitating for one hour after the melting is thorough to obtain the product. The preparation method comprises the advantages that the technology is simple and easy to control, the product is stable in quality, strong in adaptability, energy-saving and environment-friendly, convenient to use, and the like.

Owner:刘业成

High-glossiness heat sublimation transfer paper

The invention discloses high-glossiness heat sublimation transfer paper. The high-glossiness heat sublimation transfer paper comprises a paper base layer and a coating on the paper base layer, wherein the coating comprises the following components by weight: 23.5-34.5 parts of carboxymethyl cellulose, 1.5-2.5 parts of saccharose, 0.23-0.6 part of glycol ether, 6.5-7.8 parts of poly citric acid, 2.5-3.6 parts of hyaluronic acid, 4.2-5.5 parts of dibutyl phthalate, 5.5-7.8 parts of morpholine, 1.15-4.6 parts of a microcrystalline wax Jonwax26 emulsion, 2.3-3.5 parts of phthalocyanine blue, 2.5-4.5 parts of benzidine yellow, 3.6-6.5 parts of aminated resin liquid, 4.25-6.6 parts of propylene glycol monomethyl ether, 3.3-6.5 parts of titanium dioxide, 4.5-6.5 parts of trisodium phosphate anhydrous and 2.5-3.6 parts of sodium alginate. According to the high-glossiness heat sublimation transfer paper, owing to the preparation method and all components of the surface coating, the formed coating is good in glossiness, and the prepared end product is bright in pattern and longer in retention time.

Owner:苏州万敦新材料有限公司

A kind of external rubber material for flame-retardant red fire-fighting rubber hose and its preparation process

ActiveCN109206762BImprove flame retardant performanceExtended service lifeFlexible pipesRubber materialVulcanization

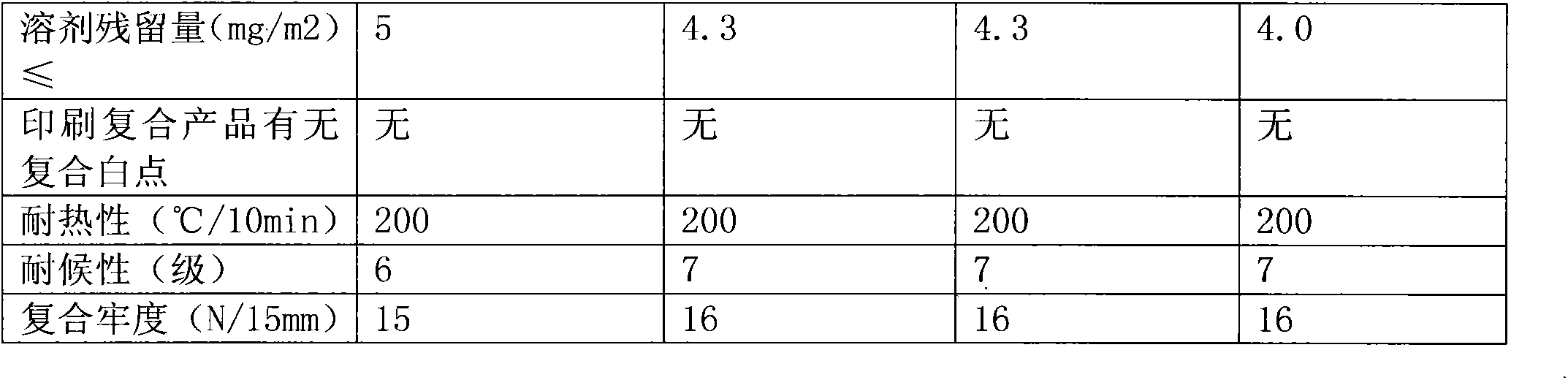

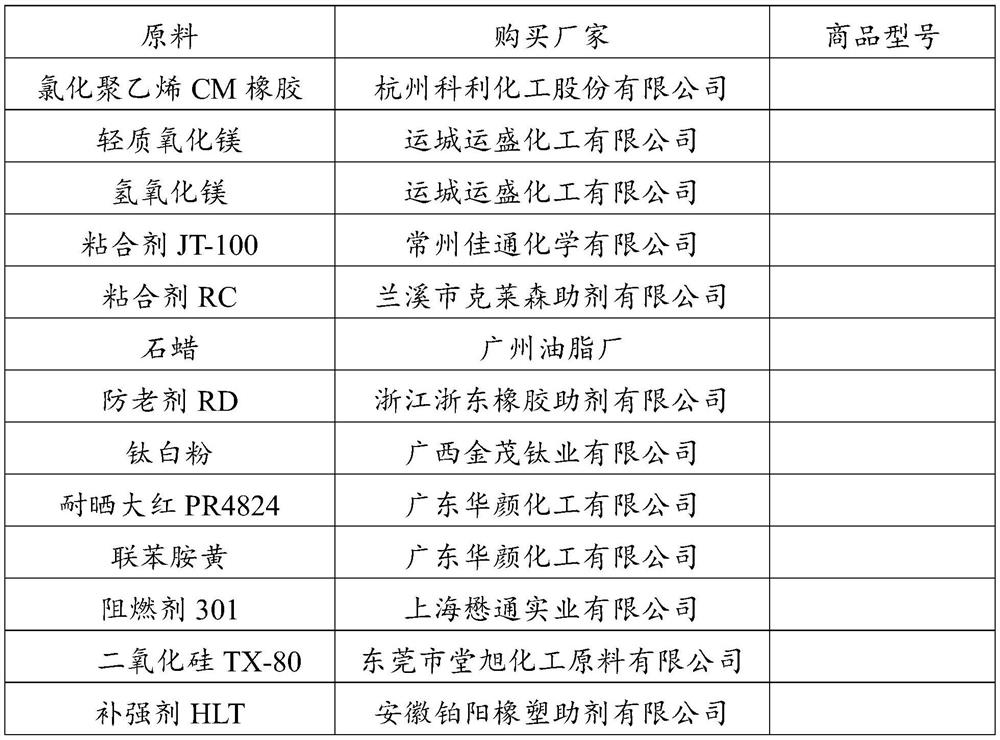

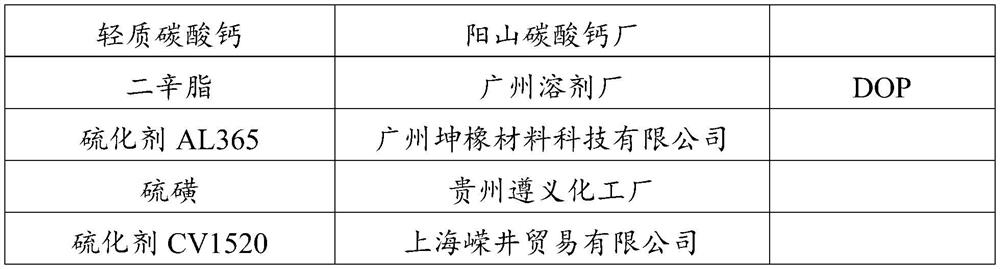

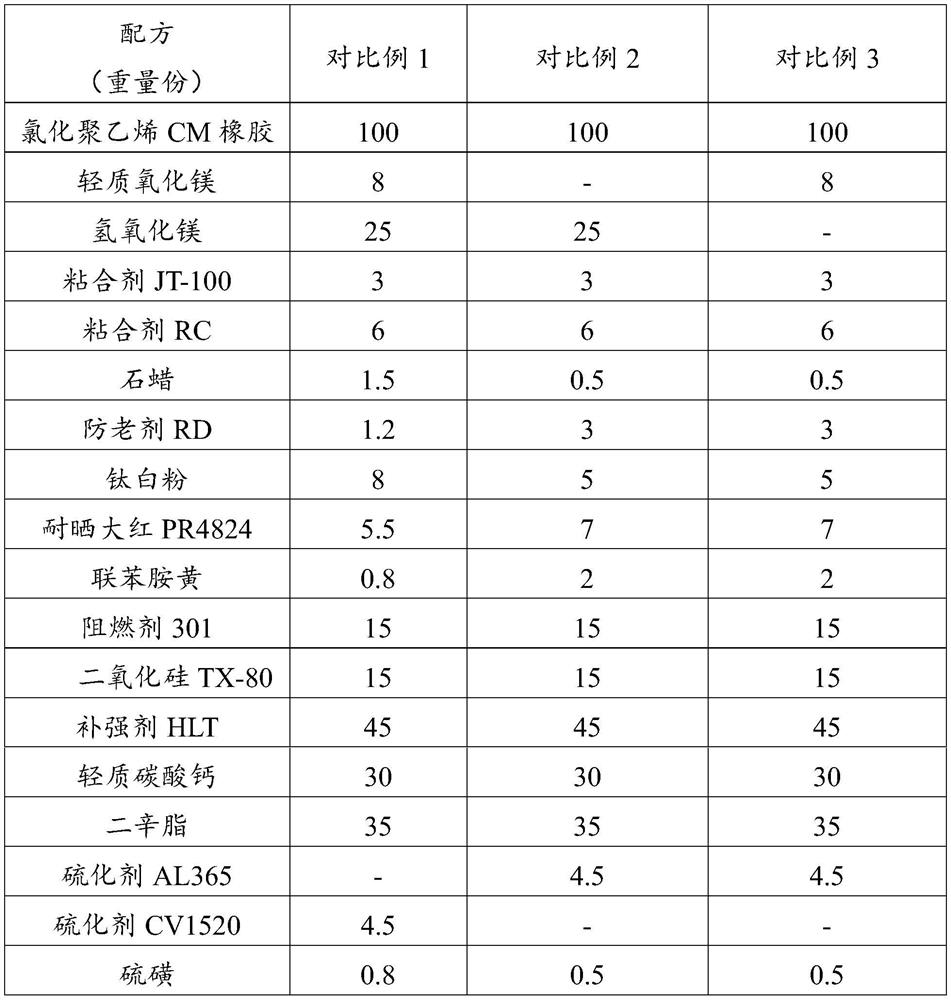

The invention discloses an outer rubber material for a flame-retardant red fire-fighting rubber hose and a preparation process thereof. The outer rubber material for a flame-retardant red fire-fighting rubber hose includes the following components in parts by weight: 100 parts of chlorinated polyethylene CM rubber , 8-12 parts of light magnesium oxide, 20-25 parts of magnesium hydroxide, 8-11 parts of adhesive, 0.8-1.5 parts of paraffin, 1-1.5 parts of anti-aging agent, 6-10 parts of titanium dioxide, and 5 parts of sun-fast scarlet ~6 parts, benzidine yellow 0.5~1 part, flame retardant 10~15 parts, silicon dioxide 15~25 parts, reinforcing agent 35~45 parts, light calcium carbonate 30~40 parts, dioctyl ester 30~ 35 parts, 4-5 parts of vulcanizing agent and 0.8-1.2 parts of sulfur. The outer rubber material of the invention is suitable for the production of conventional steam-vulcanized rubber hoses, and the outer rubber material of the invention has moderate deformation after vulcanization, lower elongation, no under-sulfur phenomenon, and high vulcanization safety. The product made of the outer rubber material of the invention is bright in color, excellent in aging resistance, good in flame retardant effect, safe and environmentally friendly, non-toxic, can effectively prolong the service life of the rubber hose, and reduce the production cost of the rubber hose.

Owner:广州连达橡塑有限公司

Non-toxic antiseptic and mildewproof water-based coating and preparation and application method thereof

InactiveCN109096840AReduce surface tensionImprove liquidityAntifouling/underwater paintsPaints with biocidesWater basedToxic material

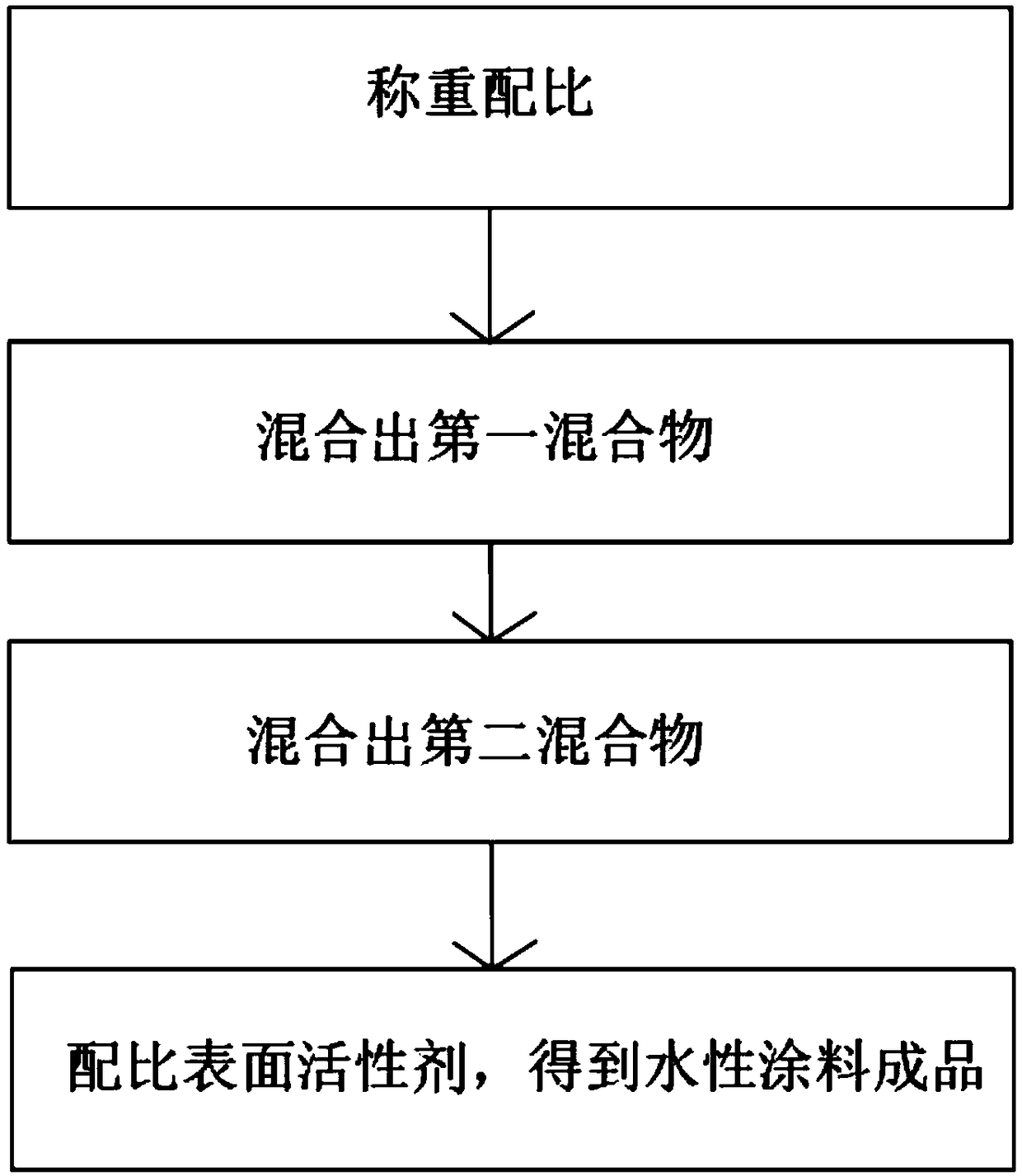

The invention discloses a non-toxic antiseptic and mildewproof water-based coating and a preparation and application method thereof. The non-toxic antiseptic and mildewproof water-based coating includes, by weight parts, 100-130 parts of water-based resin, 2 parts of anti-mold agent, 5-10 parts of preservative, 2 parts of organosilicone flatting agent, 2-8 parts of surfactant, 30-40 parts of waterand 20-30 parts of pigment, wherein the pigment comprises, by weight parts, 20-30 parts of lead chrome yellow, 10-15 parts of iron yellow, 18-25 parts of lead silicate chromate, 10-15 parts of (strontium-calcium) chrome yellow, 8-10 parts of transparent yellow, 2-10 parts of benzidine yellow, 1-8 parts of Hansha yellow and 5-7 parts of lemon yellow. The preparation method includes step S1 of weighing the raw materials in proportion, step S2 of obtaining a first mixture by mixing, step S3 of obtaining a second mixture by mixing, and step S4 of adding a surfactant at a ratio to obtain a finished product. The non-toxic antiseptic and mildewproof water-based coating is applied to architectural interior wall decorative coatings and exterior wall waterproof coatings. Application fields are widewhile a production process is simple, the production cost is greatly reduced, no toxic substance is generated in the product production and using process, and the non-toxic antiseptic and mildewproofwater-based coating can also play the role of anticorrosion and mildew prevention.

Owner:清远市承明新材料科技有限公司

High Gloss Sublimation Transfer Paper

The invention discloses high-glossiness heat sublimation transfer paper. The high-glossiness heat sublimation transfer paper comprises a paper base layer and a coating on the paper base layer, wherein the coating comprises the following components by weight: 23.5-34.5 parts of carboxymethyl cellulose, 1.5-2.5 parts of saccharose, 0.23-0.6 part of glycol ether, 6.5-7.8 parts of poly citric acid, 2.5-3.6 parts of hyaluronic acid, 4.2-5.5 parts of dibutyl phthalate, 5.5-7.8 parts of morpholine, 1.15-4.6 parts of a microcrystalline wax Jonwax26 emulsion, 2.3-3.5 parts of phthalocyanine blue, 2.5-4.5 parts of benzidine yellow, 3.6-6.5 parts of aminated resin liquid, 4.25-6.6 parts of propylene glycol monomethyl ether, 3.3-6.5 parts of titanium dioxide, 4.5-6.5 parts of trisodium phosphate anhydrous and 2.5-3.6 parts of sodium alginate. According to the high-glossiness heat sublimation transfer paper, owing to the preparation method and all components of the surface coating, the formed coating is good in glossiness, and the prepared end product is bright in pattern and longer in retention time.

Owner:苏州万敦新材料有限公司

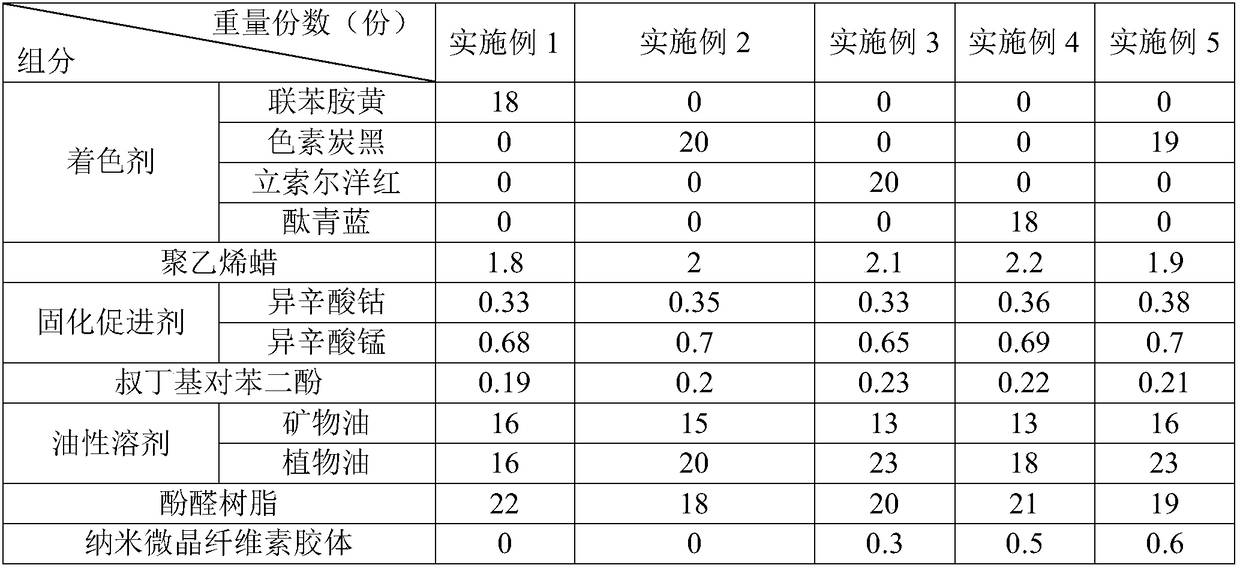

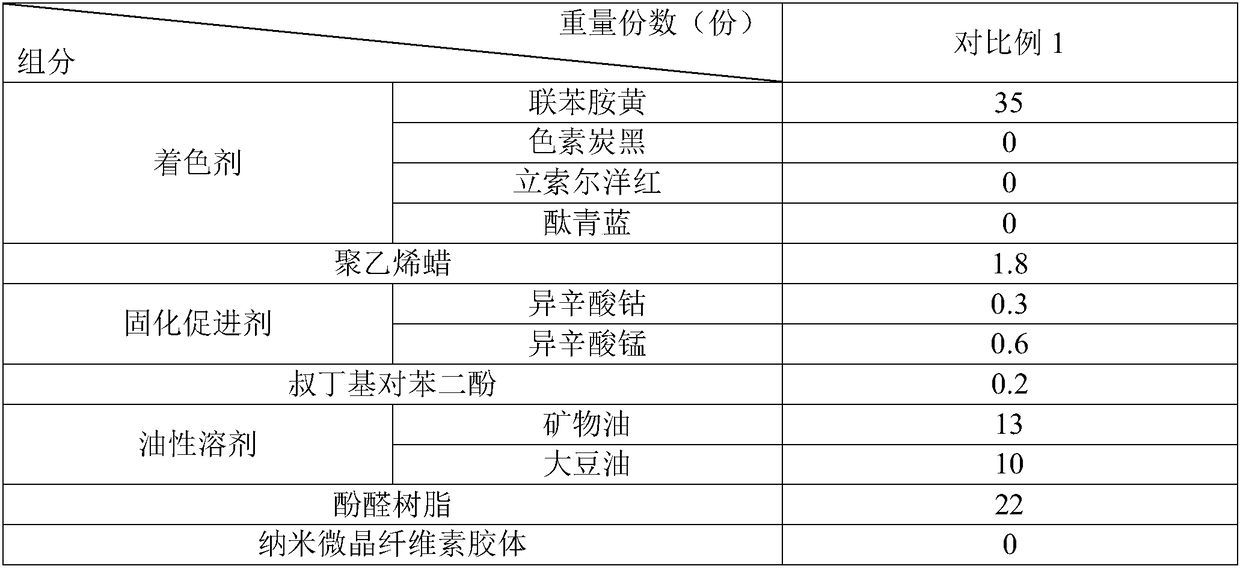

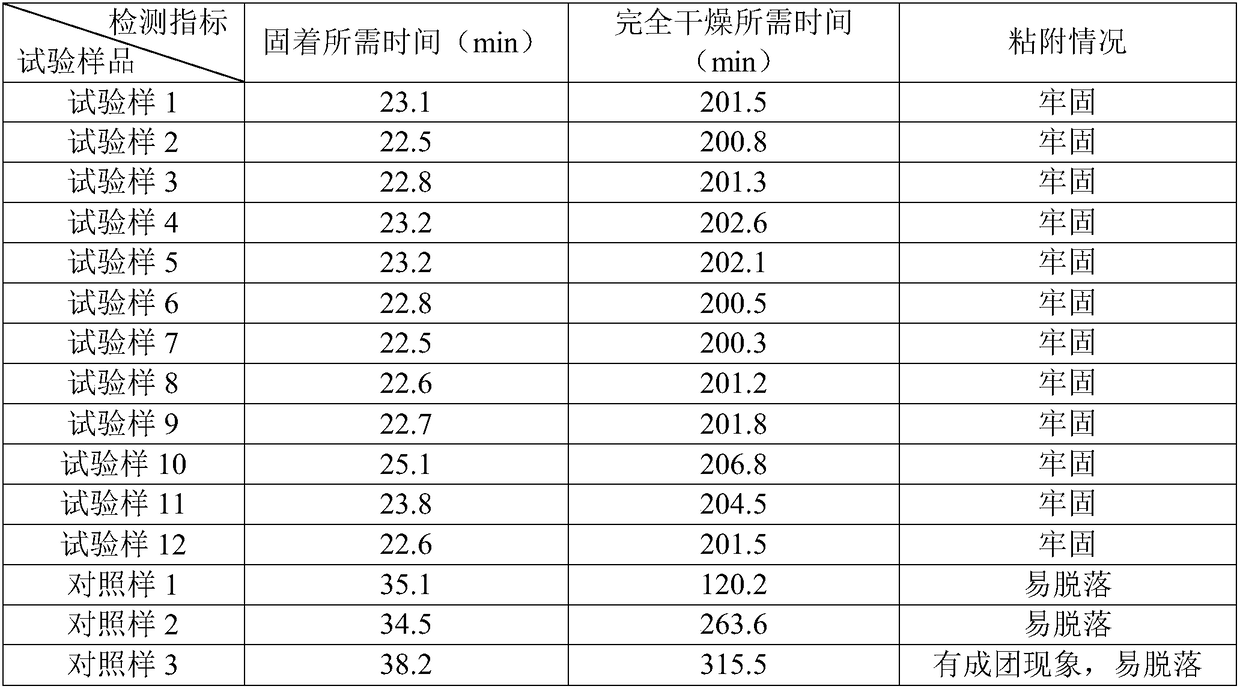

Printing ink and preparation technology thereof

Belonging to the field of printing technology, the invention discloses a printing ink and a preparation technology thereof. The printing ink comprises the following components by weight: 18-20 parts of a colorant; 0.98-1.08 parts of a curing accelerator; 0.19-0.23 part of tert-butyl hydroquinone; 31-39 parts of an oily solvent; 18-22 parts of phenolic resin; and 1.8-2 parts of polyethylene wax. The colorant includes at least one of benzidine yellow, pigment carbon black, lithol magenta and phthalocyanine blue, and has a particle size of 0.01-0.02micrometer. The curing accelerator includes at least one of cobalt iso-octoate and manganese iso-octoate. The printing ink provided by the invention has the advantages of bright color and moderate drying speed.

Owner:浙江省邮电印刷股份有限公司

Chlorinated rubber material as well as preparation method and application thereof

The invention provides a chlorinated rubber material as well as a preparation method and application thereof, and belongs to the technical field of rubber materials. The chlorinated rubber material isprepared from the following raw materials in parts by weight: 100 parts of chlorinated rubber, 30-50 parts of plasticizer DOP, 5-6 parts of activator ZnO, 4-10 parts of magnesium oxide, 1-2 parts ofactivator stearic acid, 2-3 parts of anti-ageing agent RD, 3-5 parts of anti-ageing agent 4010NA, 50-100 parts of light calcium carbonate, 3-5 parts of vulcanizing agent sulfur and 2-3 parts of accelerator. If a black material is prepared, 80-90 parts of carbon black FEF can be added; if a gray material is prepared, 80-90 parts of white carbon black, 3-15 parts of titanium dioxide and 0.3-5 part sof carbon black can be added; if a red material is prepared, 80-90 parts of white carbon black, 3-15 parts of titanium dioxide and 0.3-5 parts of permanent red can be added; if a blue material is prepared, 80-90 parts of white carbon black, 3-15 parts of titanium dioxide and 0.3-5 parts of phthalocyanine blue can be added; and if a gray material is prepared, 80-90 parts of white carbon black, 3-15parts of titanium dioxide and 0.3-5 parts of benzidine yellow can be added. The chlorinated rubber material is resistant to low temperature and abrasion, does not discolor when used as a colored rubber tube, is long in service life, resistant to ozone, bright when used as a smooth tube and high in cost performance; and the rubber material is suitable for being used as steel wire braided rubber tube outer rubber and can be widely popularized and used.

Owner:青岛威尔驰液压科技有限公司

Waterless offset printing ink and preparation method thereof

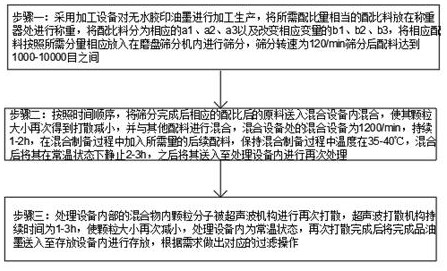

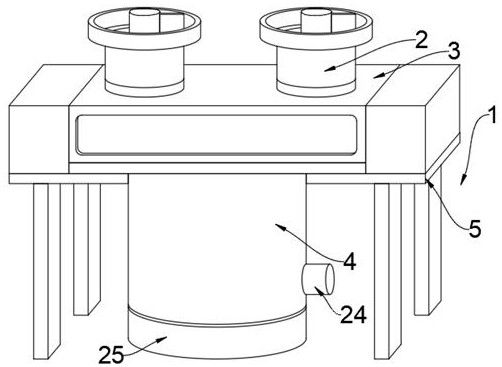

PendingCN113861756AImprove thermal stabilityImprove adaptabilityShaking/oscillating/vibrating mixersRotary stirring mixersPolymer sciencePrinting ink

The invention discloses waterless offset printing ink and a preparation method thereof, and relates to the technical field of waterless offset printing ink. The invention solves the problems that the existing waterless offset printing ink is greatly influenced by the environment temperature in the actual printing process, and the viscosity of the ink is changed due to the small change of the temperature, so that the whole waterless offset printing ink has defects in use. The printing ink includes the following components in percentage by mass: 20-30% of pigment; 30%-40% of a resin binder; 5%-8% of filler; 5%-7% of an auxiliary agent; 2%-5% of a solvent; 1-5% of a diluent; 5-15% of modified polypropylene; and 5-10% of a photostabilizer. Herein, the pigments are organic pigments including a yellow pigment, a red pigment, a blue pigment and the like, including benzidine yellow, lithol red, 6B magenta, golden light red C, 2B permanent red, phthalocyanine blue and the like; the resin binder is composed of a composition of two or more of rosin modified phenolic resin, colloid rosin modified phenolic resin, linseed oil, soybean oil and mineral oil; and the filler is a copolymer of sodium acrylate and propanamide.

Owner:苏州市大象印刷包装有限公司

A kind of enamel coating for pot body and preparation method thereof

ActiveCN110255909BImprove high temperature resistanceImprove impact performanceCooking-vessel materialsTetramethyl-p-phenylenediamineIonic liquid

The invention discloses an enamel coating for a pot body. The enamel coating is composed of the following raw materials in parts by weight: 100-150 parts of enamel frit, 4-10 parts of titanium dioxide, 0.8-1.2 parts of benzidine yellow, 1.5-3.5 parts of cage polysilsesquioxane, 1-3 parts of inorganic acid, 0.3-0.8 parts of potassium titanate, 10-30 parts of N,N,N',N'-tetramethyl-p-phenylenediamine Hydrochloride, 5-15 parts of ionic liquid and 30-50 parts of deionized water. The enamel coating for the pot body of the present invention has good high temperature resistance and corrosion resistance, can effectively slow down the phenomenon that the enamel coating of the pot body is peeled off under the action of high temperature and acid-base solution, and improves the enamel coating at the same time. Excellent sintering conditions and sintering quality make it have more excellent decorative effect and comprehensive physical properties. The invention also discloses a preparation method of the enamel coating for the pot body.

Owner:宁波市金象厨具有限公司

Pigment formula for ground mat made from EVA material

The invention discloses a pigment formula for a ground mat made from an EVA material. The pigment formula is composed of the following components by weight: 470-490g of benzidine yellow, 90-110g of titanium dioxide, 45-55g of permanent violet, 62-66kg of EVA rubber material, 23-27kg of talcum powder, 380-420g of a bridging agent, 770-830g of stearic acid, 1.9-2.1kg of zinc oxide and 7.7-8.3kg of a foaming agent. The formula has the beneficial effects that the formula is good in light resistance, heat resistance, acid and alkali resistance and solvent resistance, and the color of the produced yellow ground mat is not easy to fall off.

Owner:HENRY TATSU SUZHOU HOUSEHOLD MAT

Myopia-preventing book and manufacturing method thereof

InactiveCN110820419AImprove impactGood contrastSpecial paperNon-macromolecular organic additionColored whiteEngineering

The invention discloses a myopia-preventing book and a manufacturing method thereof. The myopia-preventing book comprises, by weight, 60-100 parts of needlebush long fiber bleached chemical pulp, 80-150 parts of mechanical wood pulp, 2-10 parts of auramine, 10-20 parts of benzidine yellow, 20-30 parts of titanium dioxide, 20-30 parts of realgar, 50-70 parts of polyacrylonitrile fiber, 1-10 parts of an acrylamide copolymer, 20-50 parts of calcium carbonate and 60-70 parts of cationic starch. Light yellow myopia-preventing paper is made in the invention, can reflect specific frequency spectrum colored light, and can be matched with other color lights to form suitable contrast in order to effectively improve the influence of white full-frequency light on eyesight, the adopted paper displays light yellow with the brightness of 60-55% and can reflect colored light with the wavelength of 500-700 nm, and enough contrast is formed between the brightness and the chromaticity of characters on the paper in order to form an optimal visual environment, so when the book is used, the myopia prevention effect can be achieved.

Owner:南京市凰凤文化传媒有限公司

Method for preparing rosin derivative for pigment industry

InactiveCN103450809BHigh tinting strengthImprove thermal stabilityNatural resin chemical modificationReaction temperatureAlkylphenol

The invention discloses a method for preparing a rosin derivative for the pigment industry and relates to the technical field of deep processing of rosin. The method comprises the following steps of: adding alkylphenol disulfide which accounts for 0.1-1.0% of the total mass of rosin into the rosin and carrying out disproportionation reaction, wherein the reaction temperature is 260-280 DEG C and the reaction time is 2-6 hours; cooling down after the reaction is accomplished; adding tannic acid which accounts for 0.3-1.0% of the total mass of the rosin at 160-200 DEG C; stirring and reacting for 1-3 hours; and taking out the product which is the rosin derivative. Compared with the prior art, the rosin derivative can improve the tinting strength of the pigment, is high in transparency and is nature and environment-friendly. The rosin derivative is mainly applied to industries such as pigment synthesis and is particularly applicable to preparation of benzidine yellow pigment with high additive amount.

Owner:WUZHOU PINE CHEM

Quick-drying UV-curing ink and preparation method thereof

The invention discloses quick-drying UV-curing ink. The quick-drying UV-curing ink comprises the following components in parts by weight: 6-15 parts of a photoinitiator, 55-78 parts of a connecting material, 15-25 parts of a pigment, and 1-5 parts of an auxiliary agent, wherein the connecting material comprises a monomer diluent and a prepolymer, the pigment includes a combination of at least oneselected from benzidine yellow, iron oxide yellow, phthalocyanine blue, magenta, Lithol red, titanium white and carbon black, and the auxiliary agent comprises a combination of wax and one or two selected from an antifoaming agent and a levelling agent. The invention also discloses a preparation method of the quick-drying UV-curing ink. The quick-drying UV-curing ink disclosed by the invention canmeet the drying requirement of 15000 / hour high-speed printing of a UV printing machine, and a residual amount of a solvent meets an SN / T3551-2013 standard; the ink has the advantages of quick drying,good printing suitability, a good fixing effect and a low residual amount of the light initiator, and good safety and environmental protection performance, and is suitable for the fields of food andpharmaceutical packaging; and the raw material synthesis costs are low, and investment of the costs is reduced.

Owner:GUANGDONG ZHUANGLI COLOR PRINTING

Printing ink convenient to process

The invention discloses printing ink convenient to process. The printing ink convenient to process comprises a binder, filler, a diluent, a viscosity reducer, a surfactant, a photopolymerization initiator, a pigment and a solvent, wherein the binder is polyamide resin, the filler is quartz powder, the diluent is powdered kaolin, the viscosity reducer is linseed oil, the surfactant is lecithin, the photopolymerization initiator is benzoin isopropyl ether, the pigment is benzidine yellow, and the solvent is ethyl acetate. The printing ink convenient to process comprises the binder, the filler, the diluent, the viscosity reducer, the surfactant, the photopolymerization initiator, the pigment and the solvent and has the characteristics of low cost, convenience in processing, high quality, high processing efficiency, bright color and good usage effect.

Owner:SUZHOU YONGJIN COLOR PRINTING PACKAGING

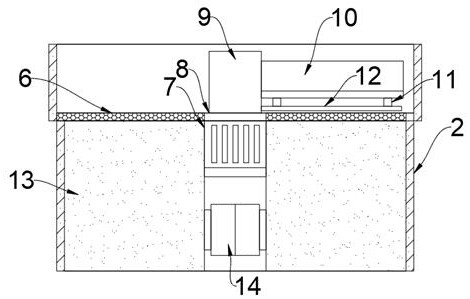

Anti-blue light screen protective film and preparation method thereof

ActiveCN103991255BAvoid damageUniform thicknessSynthetic resin layered productsLaminationDimethyl siloxaneBlocking layer

The invention discloses a blue-light-prevention screen protective membrane and a preparation method of the blue-light-prevention screen protective membrane, wherein the blue-light-prevention screen protective membrane is composed of a scrape-resistant coating, a film substrate layer, a blue light blocking layer and a release membrane layer; one surface of film substrate layer is coated by the scrape-resistant coating; the other surface of the film substrate layer is coated by the blue light blocking layer; the other surface of the blue light blocking layer is coated by the release membrane layer. The blue light blocking layer consists of the following components in parts by mass: 150 parts of methyl MQ silicon resin, 80-120 parts of terminated polydimethylsiloxane, 4.14-5.94 parts of 2, 4-dichlorobenzoyl peroxide, 0.27-5.06 parts of benzotriazole and 0.027-0.115 part of azo-type benzidine yellow. The blue-light-prevention screen protective membrane provided by the invention can resist blue light with the wavelength of 380-480nm, reduces the injury of blue light to retina, moreover has favorable visible light transmittance, and can be effectively compatible with visible light transmittance and blue light blocking rate; the coating is uniform and controllable in thickness; the preparation process is simple and low in cost.

Owner:TAIHU JINZHANG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com