Metal etching agent used for etching copper-containing metal layer and preparation method for metal etching agent

A metal etching, copper metal technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of slow etching efficiency, difficult to use effect to meet the needs of users, etc., to improve etching efficiency, excellent flatness , the effect of a good tapered profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

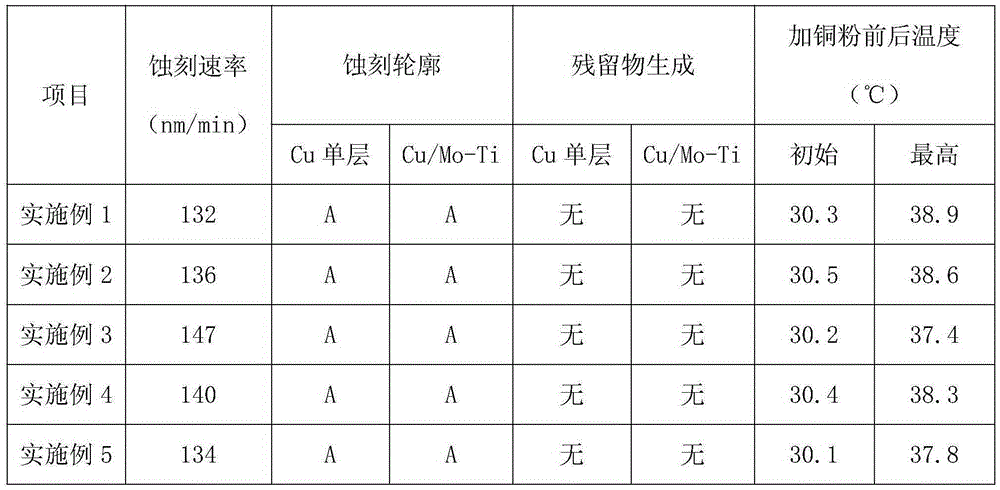

Examples

Embodiment 1

[0017] A metal etchant for etching copper-containing metal layers, which is composed of the following raw materials in parts by weight: 20 parts of hydrogen peroxide, 1 part of acetic acid, 1 part of nitrilotriacetic acid, 10 parts of sodium carboxymethyl cellulose, boric acid 15 parts, 12 parts of sodium fumarate, 1 part of sodium fluoride, 4 parts of ethylene glycol, 2 parts of benzidine yellow, 6 parts of barium stearate, 8 parts of azobisisobutyronitrile.

[0018] The method for preparing the metal etchant for etching the copper-containing metal layer described in this embodiment includes the following steps:

[0019] 1) Measure acetic acid, sodium carboxymethyl cellulose, boric acid, sodium fumarate, sodium fluoride, ethylene glycol and benzidine yellow, add them to the container, heat to 50°C, stir and mix for 5 minutes to obtain the first mixture liquid;

[0020] 2) Cool the first mixed solution to room temperature naturally, weigh out and add barium stearate, heat to 42°C, s...

Embodiment 2

[0024] A metal etchant for etching copper-containing metal layers, which is composed of the following raw materials in parts by weight: 30 parts of hydrogen peroxide, 5 parts of acetic acid, 3 parts of nitrilotriacetic acid, 15 parts of sodium carboxymethyl cellulose, boric acid 20 parts, 14 parts sodium fumarate, 2 parts sodium fluoride, 10 parts ethylene glycol, 10 parts benzidine yellow, 8 parts barium stearate, 12 parts azobisisobutyronitrile.

[0025] The method for preparing the metal etchant for etching the copper-containing metal layer described in this embodiment includes the following steps:

[0026] 1) Measure acetic acid, sodium carboxymethyl cellulose, boric acid, sodium fumarate, sodium fluoride, ethylene glycol and benzidine yellow, add them to the container, heat to 60°C, stir and mix for 10 minutes to obtain the first mixture liquid;

[0027] 2) Cool the first mixed liquid to room temperature naturally, weigh and add barium stearate, heat to 48°C, stir and mix for 1...

Embodiment 3

[0031] A metal etchant for etching copper-containing metal layers, which is composed of the following raw materials in parts by weight: 25 parts of hydrogen peroxide, 3 parts of acetic acid, 2 parts of nitrilotriacetic acid, 13 parts of sodium carboxymethyl cellulose, boric acid 18 parts, 13 parts of sodium fumarate, 2 parts of sodium fluoride, 6 parts of ethylene glycol, 6 parts of benzidine yellow, 7 parts of barium stearate, 10 parts of azobisisobutyronitrile.

[0032] The method for preparing the metal etchant for etching the copper-containing metal layer described in this embodiment includes the following steps:

[0033] 1) Measure acetic acid, sodium carboxymethylcellulose, boric acid, sodium fumarate, sodium fluoride, ethylene glycol and benzidine yellow, add them to the container, heat to 55°C, stir and mix for 8 minutes to obtain the first mixture liquid;

[0034] 2) Cool the first mixed liquid to room temperature naturally, weigh and add barium stearate, heat to 45°C, stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com